Europium-doped calcium silicate luminescent material and preparation method and application thereof

A technology of calcium aluminosilicate and luminescent materials, applied in luminescent materials, electroluminescent light sources, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

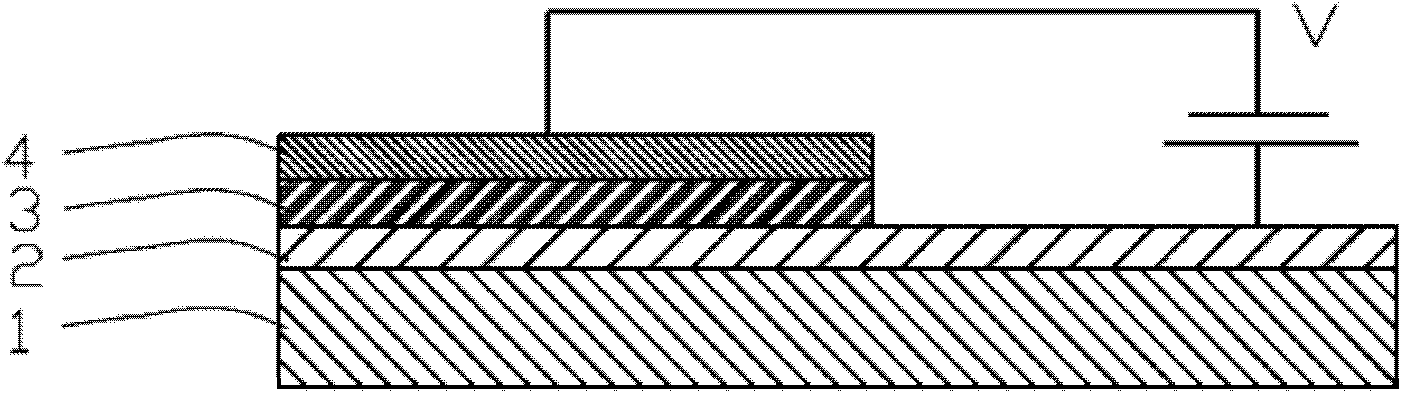

[0022] The preparation method of the above-mentioned europium-doped calcium aluminosilicate luminescent material comprises the following steps:

[0023] Step S11, according to CaAl 2 Si 2 o 8 :xEu 3+ The stoichiometric ratio of each element weighs CaO, Al 2 o 3 , SiO 2 and Eu 2 o 3 Powder, where 0.0005≤x≤0.09.

[0024] In this step, preferably, x is 0.0045.

[0025] It can be understood that CaO, Al can also be weighed in this step 2 o 3 , SiO 2 and Eu 2 o 3 Powder and mixed evenly, the mass percentage of CaO is 20%~30%, Al 2 o 3 The mass percentage of Eu is 28%~43%, Eu 2 o 3 The mass percentage content is 0.01 ~ 2%, and the balance is SiO 2 . Preferably, the mass percentage of CaO is 24%, Al 2 o 3 The mass percentage content is 32%, Eu 2 o 3 The mass percentage content is 0.5%.

[0026] Step S12, sintering the mixed powder at 900° C. to 1300° C. for 0.5 hours to 5 hours to obtain the target product.

[0027] In this step, it is preferable to sinter at...

Embodiment 1

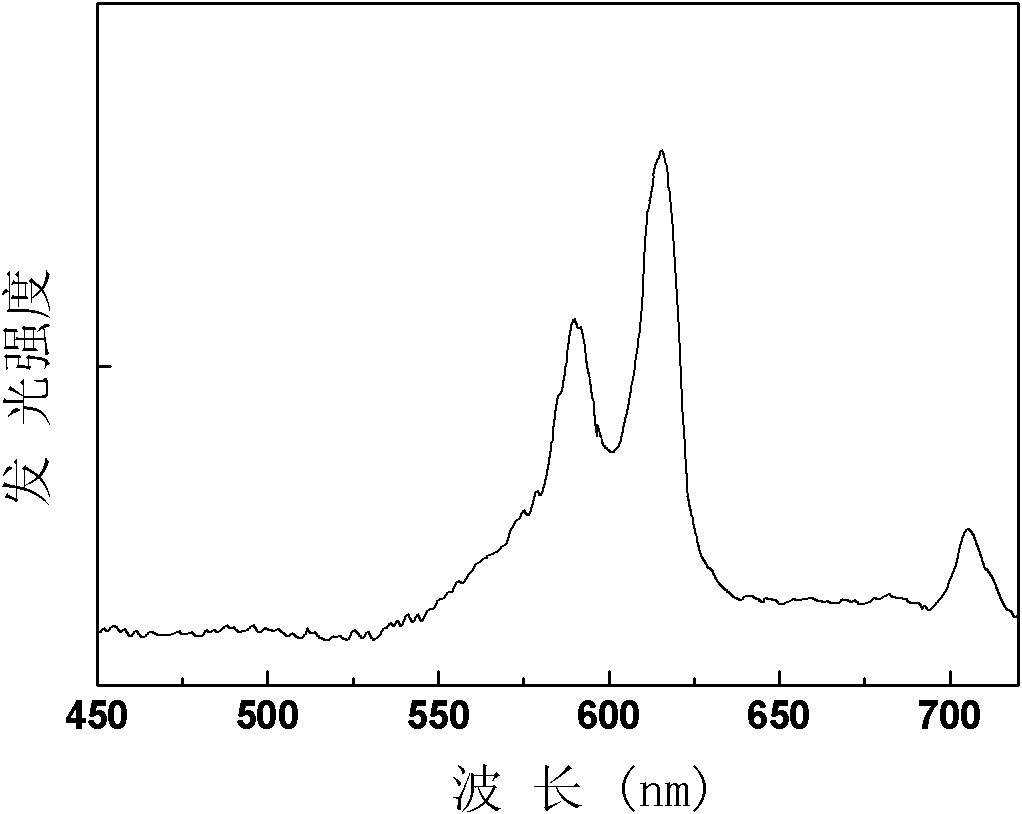

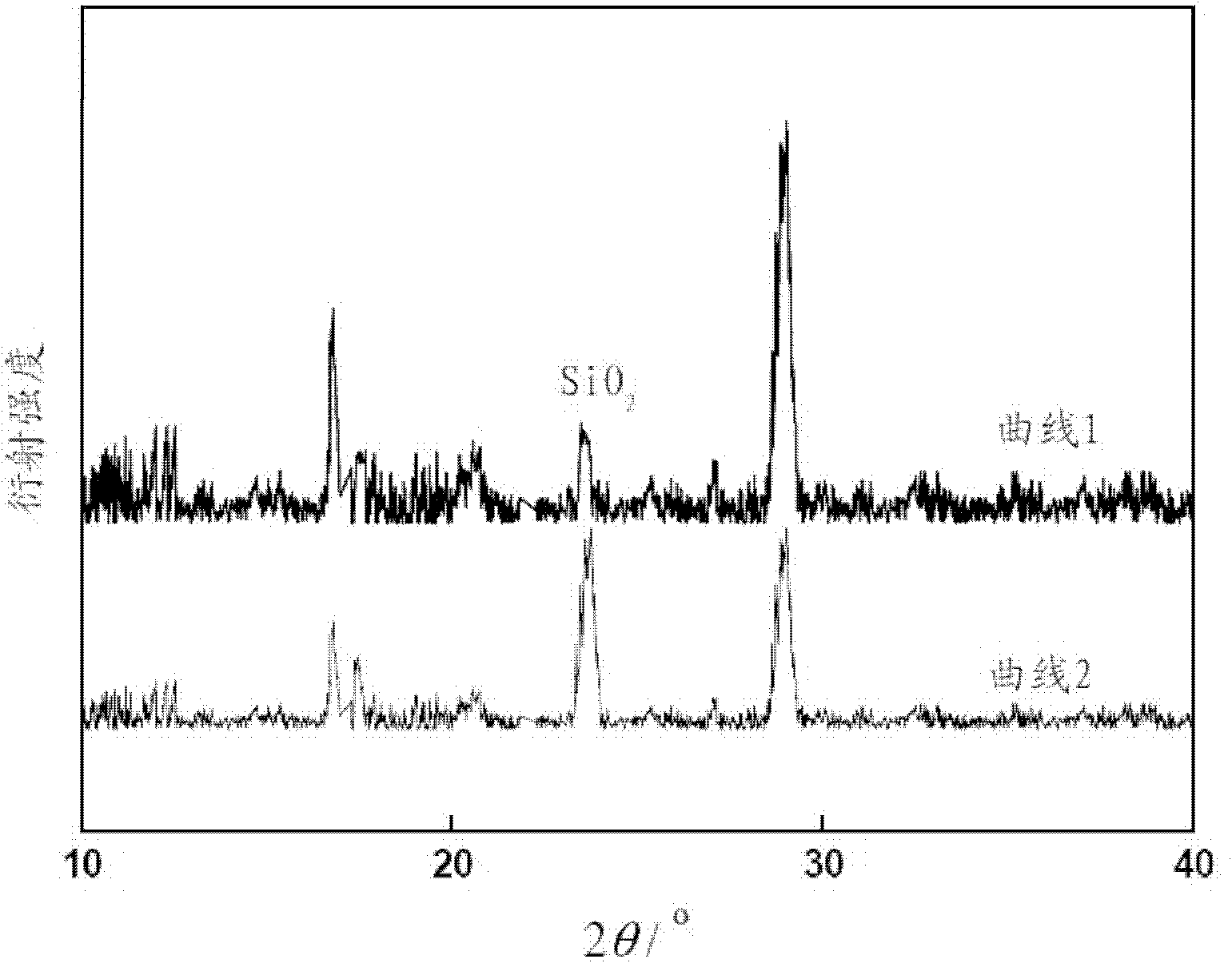

[0044] Selecting the powder with a purity of 99.99%, the CaO with a mass percentage of 24%, and the Al with a mass percentage of 32% 2 o 3 , the mass percentage is 0.5% Eu 2 o 3 and SiO with a mass percentage of 43.5% 2 , after uniform mixing, sintering at 1250° C. for 3 hours to form a ceramic target with a diameter of 50 mm and a thickness of 2 mm, and the target was loaded into a vacuum chamber. Then, the glass substrate with indium tin oxide (ITO) was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, treated with oxygen plasma, and placed in a vacuum chamber. The distance between the target and the substrate is set to 60mm. Use a mechanical pump and a molecular pump to pump the vacuum of the cavity to 5.0×10 -4 Pa, the working gas flow rate of argon is 25 sccm, the pressure is adjusted to 2.0 Pa, and the substrate temperature is 500°C. The obtained samples were annealed in a 0.01 Pa vacuum furnace for 2 h at a temperature of 600 ...

Embodiment 2

[0049] Select the powder with a purity of 99.99%, and the mass percentage is 20% CaO, and the mass percentage is 43% Al 2 o 3 , with a mass percentage of 0.01% Eu 2 o 3 and SiO with a mass percentage of 36.99% 2 , after uniform mixing, sintering at 900°C to form a ceramic target with a diameter of 50mm and a thickness of 2mm, and put the target into a vacuum chamber. Then, the glass substrate with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, treated with oxygen plasma, and placed in a vacuum chamber. The distance between the target and the substrate was set to 45 mm. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 1.0×10 -3 Pa, the working gas flow rate of argon is 10 sccm, the pressure is adjusted to 0.2 Pa, and the substrate temperature is 250°C. The obtained samples were annealed in a 0.01 Pa vacuum furnace for 1 h at an annealing temperature of 500 °C. Then a layer of Ag is vapor-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com