Concrete-poured sandwich metal plate type composite armor and manufacture method thereof

A sandwich and concrete technology, applied to the structure of the armor plate, etc., can solve the problems of lack of resistance to repeated strikes, large damage range of the target plate, and increased vehicle load, etc., to achieve increased toughness and impact resistance. The effect of impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

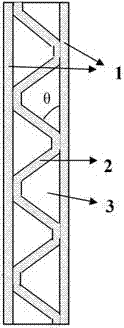

[0034] In this embodiment, a method for preparing concrete pouring sandwich metal plate type composite armor comprises the following steps:

[0035] 1) Preparation of sandwich metal sandwich panels: In this embodiment, the metal front panel 1-1, the metal rear panel 1-2 and the metal core 2 are made of armored steel. , using the sandblasted armor steel plate as the material, a metal core 2 with a thickness of 1 mm and an angle θ of 50° is prepared by hydraulic press molding or bending by a cold bender, and then the armor steel front panel and armor steel rear panel with a thickness of 1 mm The metal core 2 is welded layer by layer between the panels to obtain a sandwich metal sandwich panel;

[0036] 2) Preparation of concrete 3: Mix water, 52.5# cement, silica fume, quartz sand, high-efficiency water reducer, steel fiber or iron powder as raw materials, and mechanically stir for 3 minutes to obtain active powder concrete; silica fume accounts for cement and 20% of the total ...

Embodiment 2

[0039] In this embodiment, a method for preparing concrete pouring sandwich metal plate type composite armor comprises the following steps:

[0040] 1) Preparation of sandwich metal sandwich panels: In this embodiment, the metal front panel 1-1, the metal rear panel 1-2 and the metal core 2 are made of alloy aluminum. , using the sandblasted alloy aluminum plate as the material, a metal core 2 with a thickness of 0.6 mm and an angle θ of 75° is prepared by hydraulic molding or cold bending machine bending, and the metal core 2 is molded by a hydraulic press or cold bending machine Bending to obtain a corrugated structure; then welding the metal core 2 layer by layer between the alloy aluminum front panel and the alloy aluminum rear panel with a thickness of 0.6mm to obtain a sandwich metal sandwich panel;

[0041] 2) Preparation of concrete 3: Mix water, 52.5# cement, silica fume, quartz sand, high-efficiency water reducer, steel fiber or iron powder as raw materials, and mech...

Embodiment 3

[0044] In this embodiment, a method for preparing concrete pouring sandwich metal plate type composite armor comprises the following steps:

[0045]1) Preparation of sandwich metal sandwich panels: In this embodiment, the metal front panel 1-1, the metal rear panel 1-2 and the metal core 2 are made of stainless steel. The sandblasted stainless steel plate is used as the material, and the metal core 2 with a thickness of 0.6mm and an angle θ of 10° is prepared by hydraulic press molding or bending by a cold bender, and then the stainless steel front panel and stainless steel rear panel with a thickness of 0.6mm The metal core 2 is welded layer by layer to obtain a sandwich metal sandwich panel;

[0046] 2) Preparation of concrete 3: Mix water, 52.5# cement, silica fume, quartz sand, high-efficiency water reducer, steel fiber or iron powder as raw materials, and mechanically stir for 15 minutes to obtain active powder concrete; silica fume accounts for cement and 5% of the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com