Chinese yam drink production method

A production method and yam technology, which is applied in the field of yam beverage production, can solve problems affecting product taste and quality, discontinuous production, low production efficiency, etc., achieve good peeling effect, reduce production feasible cost, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

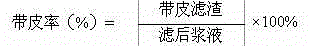

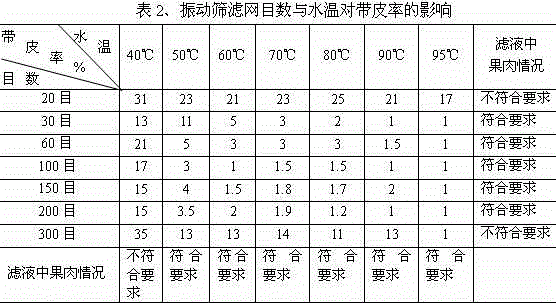

Method used

Image

Examples

Embodiment 1

[0018] A kind of production method of yam beverage, it comprises the steps:

[0019] 1) Wash 20 selected fresh yams (parts by weight, the same below) free from pests, impurities, and deterioration, cut into sections, pre-boil at 86°C for 10 minutes, remove, transfer to a colloid mill and add 65 Start pulping (grinding 3 times) after water with a temperature of 80°C, and adjust the gap between the grinding discs of the colloid mill to 8 μm;

[0020] 2) The slurry obtained from pulping is filtered by the sprinkler to the vibrating screen. The filter screen is 50 mesh. The filtrate is pumped into the blending tank, and auxiliary materials are added to the blending tank (the auxiliary materials consist of 8 parts of white sugar, 0.2 parts of pectin and 0.3 parts of carboxymethyl Base cellulose sodium) after mixing, add purified water to make the volume to 100 parts, homogenize, degas, fill, sterilize and pack to obtain the finished beverage.

Embodiment 2

[0022] A kind of production method of yam beverage, it comprises the steps:

[0023] 1) Wash and cut 20 parts of selected fresh yams (parts by weight, the same below) at 83°C for 20 minutes, take them out, transfer them to a colloid mill and add 80 parts of water at a temperature of 60°C Start pulping (grinding 2 times), and adjust the disc gap of the colloid mill to 15 μm;

[0024] 2) The slurry obtained from pulping is filtered by the sprinkler to the vibrating screen. The filter screen is 100 mesh. The filtrate is pumped into the blending tank, and auxiliary materials are added to the blending tank (the auxiliary materials consist of 6 parts of white sugar, 0.3 parts of pectin and 0.2 parts of carboxymethyl Base cellulose sodium) after mixing, add purified water to make the volume to 100 parts, homogenize, degas, fill, sterilize and pack to obtain the finished beverage.

Embodiment 3

[0026] A kind of production method of yam beverage, it comprises the steps:

[0027] 1) Wash and cut 40 parts of selected fresh yams (parts by weight, the same below) at 88°C for 20 minutes, take them out, transfer them to a colloid mill and add 240 parts of water at a temperature of 70°C Start pulping (grinding 3 times), and adjust the disc gap of the colloid mill to 25 μm;

[0028] 2) The slurry obtained from pulping is filtered by the sprinkler to the vibrating screen. The filter screen is 200 mesh. The filtrate is pumped into the blending tank, and auxiliary materials are added to the blending tank (the auxiliary materials consist of 8 parts of white sugar, 0.2 parts of pectin and 0.3 parts of carboxymethyl Base cellulose sodium) after mixing, add purified water to make the volume to 100 parts, homogenize, degas, fill, sterilize and pack to obtain the finished beverage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com