Slurry bed methanation catalyst, preparing method and application

A methanation catalyst and slurry bed technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the limitation of the industrialization process of the slurry bed methanation process, catalyst particle size, strength and low temperature reaction performance can not be better satisfied, Increase catalyst wear and other problems, achieve the effect of increasing low-temperature activity, small particle size, and good catalytic methanation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

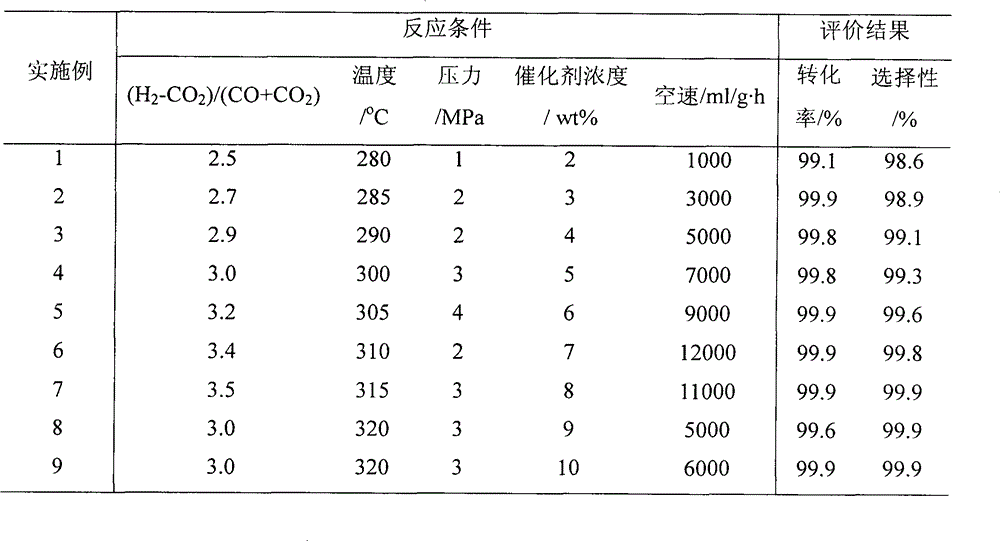

Examples

Embodiment 1

[0026] Carrier pretreatment: 60-80 mesh, specific surface area is 150m 2 / g γ-Al 2 o 3 Calcination at 400°C for 1h; impregnation: 2.43g of NiCl 2 ·6H 2 O was dissolved in 15ml of water and mixed with 10g of calcined γ-Al 2 o 3 Equal volume immersion at room temperature for 5 hours;

[0027] ·Drying and roasting: put the impregnated sample into an oven and dry at 90°C for 5h, grind the dried powder and place it in a muffle furnace and roast at 350°C for 6h to obtain NiO / γ-Al 2 o 3 Prebody;

[0028] Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor body is composed of 5% H in volume 2 with 95%N 2 Ni / γ-Al was obtained after reduction at 450℃ for 12h in a mixed atmosphere 2 o 3 , the composition of the product catalyst is: Ni5wt%, γ-Al 2 o 3 95wt%;

[0029] The catalyst prepared in this embodiment is carried out in a 500ml slurry bed high-pressure reactor, and the reaction conditions and performance evaluation results are shown in Attached Table 1. The specific step...

Embodiment 2

[0032] Carrier pretreatment: 80-100 mesh, specific surface area is 200m 2 / g γ-Al 2 o 3 Roast at 450°C for 1.5h;

[0033] Impregnation: 4.86gNiCl 2 ·6H 2 O and O.14gMoCl 5 Dissolve in 15ml of water and mix it with 10g of roasted γ-Al 2 o 3 Equal volume immersion at room temperature for 10 hours;

[0034] Drying and roasting: put the impregnated sample into an oven and dry at 100°C for 10h, grind the dried powder and place it in a muffle furnace and roast at 400°C for 5h to obtain NiO / γ-Al 2 o 3 Prebody;

[0035] Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor body is composed of 10% H in volume 2 with 90%N 2 Ni / γ-Al was obtained after reduction at 500℃ for 10h in a mixed atmosphere 2 o 3, the composition of the product catalyst is: Ni 9.05wt%, Mo 0.45wt%, γ-Al 2 0 3 90.50wt%;

[0036] The catalyst prepared in this example was carried out in a 500ml slurry bed high-pressure reactor, and the reaction conditions and performance evaluation results are shown in ...

Embodiment 3

[0038] Carrier pretreatment: 100-120 mesh, specific surface area is 250m 2 / g γ-Al 2 o 3 Calcined at 500°C for 2h;

[0039] Impregnation: 7.29gNiCl 2 ·6H 2 O and 0.31gLa(NO 3 ) 3 ·6H 2 O was dissolved in 15ml of water and mixed with 10g of calcined γ-Al 2 o 3 Equal volume immersion at room temperature for 15 hours;

[0040] ·Drying and roasting: put the impregnated sample into an oven and dry at 110°C for 15h, grind the dried powder and place it in a muffle furnace and roast at 450°C for 4h to obtain NiO / γ-Al 2 o 3 Prebody;

[0041] Hydrogen reduction: NiO / γ-Al 2 o 3 The precursor body is composed of 15% H in volume 2 with 95%N 2 Ni / γ-Al was obtained after reduction at 550°C for 8 hours in a mixed atmosphere 2 o 3 , the composition of the product catalyst is: Ni12.93wt%, La 0.86wt%, γ-Al 2 o 3 86.21wt%;

[0042] The catalyst prepared in this example was carried out in a 500ml slurry bed high-pressure reactor, and the reaction conditions and performance eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com