Dinnerware made from bran

A bran and tableware technology, which is applied in the field of environmental protection new material products, can solve problems such as unfavorable environmental protection, accumulation, waste of resources, etc., and achieve the effects of avoiding cross infection of diseases, simple production process and rich materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

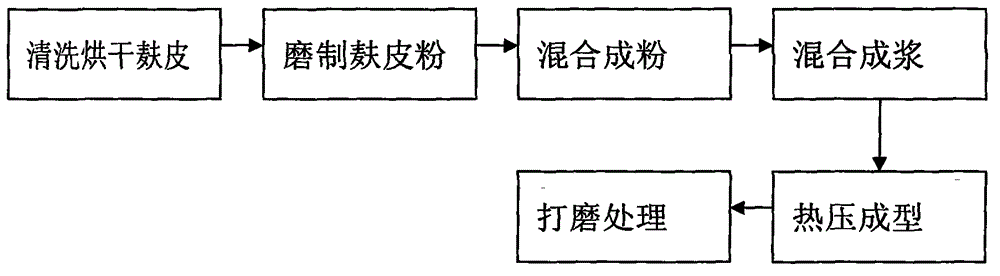

[0033] The production process of the tableware made of crop bran, the specific production process is:

[0034] The first step is to clean the crop bran to remove dust and stale matter, then dry and grind it into a 90-mesh dry crop bran powder;

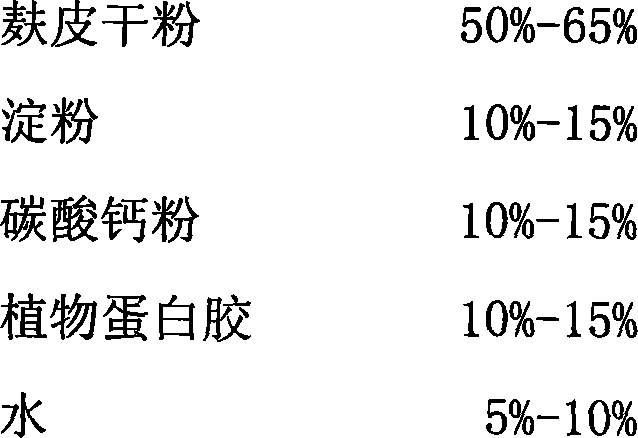

[0035] In the second step, the dry crop bran powder, starch, calcium carbonate powder, and vegetable protein glue are weighed and mixed according to the proportions of 50%, 10%, 15%, and 15%, respectively, and the four dry powders are stirred and mixed evenly to form a mixed powder;

[0036] The third step is to add water into the mixed powder according to the proportion of 10% water, and stir it. It takes 30 minutes to stir, and it is prepared into a viscous slurry;

[0037] Step 4: Pour the powder slurry into a hot press molding machine according to a certain amount, and extrude the tableware; the powder slurry is extruded under high temperature and high pressure, and the temperature during extrusion is 300°C, and the tableware is ex...

Embodiment 2

[0040] The production process of the tableware made of crop bran, the specific production process is:

[0041] The first step is to clean the crop bran to remove dust and stale matter, then dry and grind it into a 70-mesh dry crop bran powder;

[0042] In the second step, the dry crop bran powder, starch, calcium carbonate powder, and vegetable protein glue are weighed and mixed according to the proportions of 65%, 10%, 10%, and 10%, respectively, and the four dry powders are stirred and mixed evenly to form a mixed powder;

[0043] The third step is to add water into the mixed powder according to the proportion of 5% water, and stir it. It takes 30 minutes to stir, and it is prepared into a viscous slurry;

[0044] Step 4: Pour the powder slurry into a hot press molding machine according to a certain amount, and extrude the tableware; the powder slurry is extruded under high temperature and high pressure, and the temperature during extrusion is 500°C, and the tableware is ext...

Embodiment 3

[0047] The production process of the tableware made of crop bran, the specific production process is:

[0048] The first step is to clean the crop bran to remove dust and stale matter, then dry and grind it into a 90-mesh dry crop bran powder;

[0049] In the second step, dry crop bran powder, starch, calcium carbonate powder, and vegetable protein glue are weighed and mixed according to the proportions of 52%, 15%, 13%, and 12%, respectively, and the four dry powders are stirred and mixed evenly to form a mixed powder;

[0050] The third step is to weigh and add water to the mixed powder according to the proportion of 8% water, and stir it. It takes 30 minutes to stir, and it is prepared into a viscous powder slurry;

[0051] The fourth step is to pour the powder slurry into a hot press molding machine according to a certain amount, and extrude the tableware; the powder slurry is extruded under high temperature and high pressure, and the temperature during extrusion is 400 ° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com