Double-sided pressure-sensitive adhesive sheet

A pressure-sensitive adhesive sheet, pressure-sensitive adhesive technology, applied in the direction of pressure-sensitive films/sheets, adhesives, adhesive products, etc., can solve the problems of removability (deterioration of rework performance, etc., achieve excellent removability, improve anchoring Excellent performance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] (Preparation of evaluation samples)

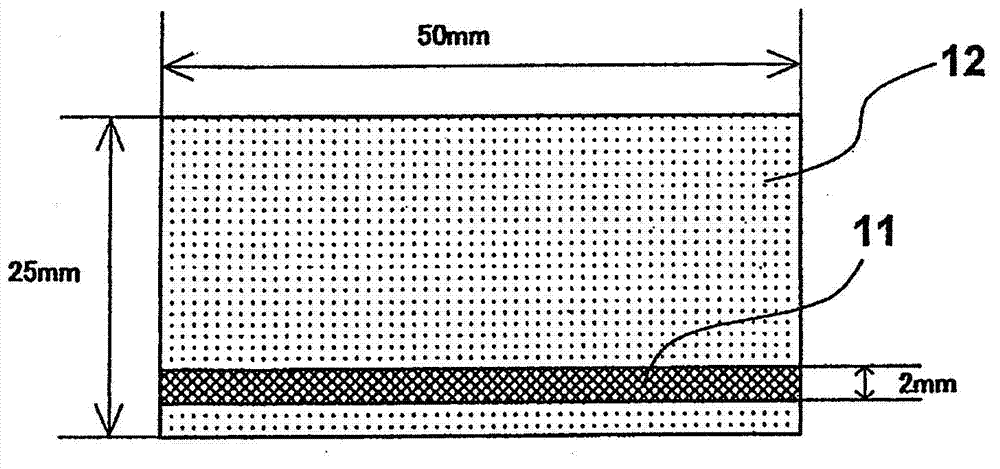

[0082] figure 1 is a schematic diagram (plan view) showing a polyolefin foam substrate (evaluation sample) fixed to an evaluation board for the dent test. exist figure 1 Among them, 11 denotes a polyolefin foam substrate, and 12 denotes an evaluation board.

[0083]The polyolefin foam base material was cut into a sheet having a width of 2 mm and a length of 50 mm to prepare an evaluation sample. Then, the polyolefin foam substrate 11 (evaluation sample) was attached to an evaluation board 12 (acrylic board, size: width 25 mm, length 50 mm, thickness 5 mm) (reference figure 1 ).

[0084] (Determination of dent resistance)

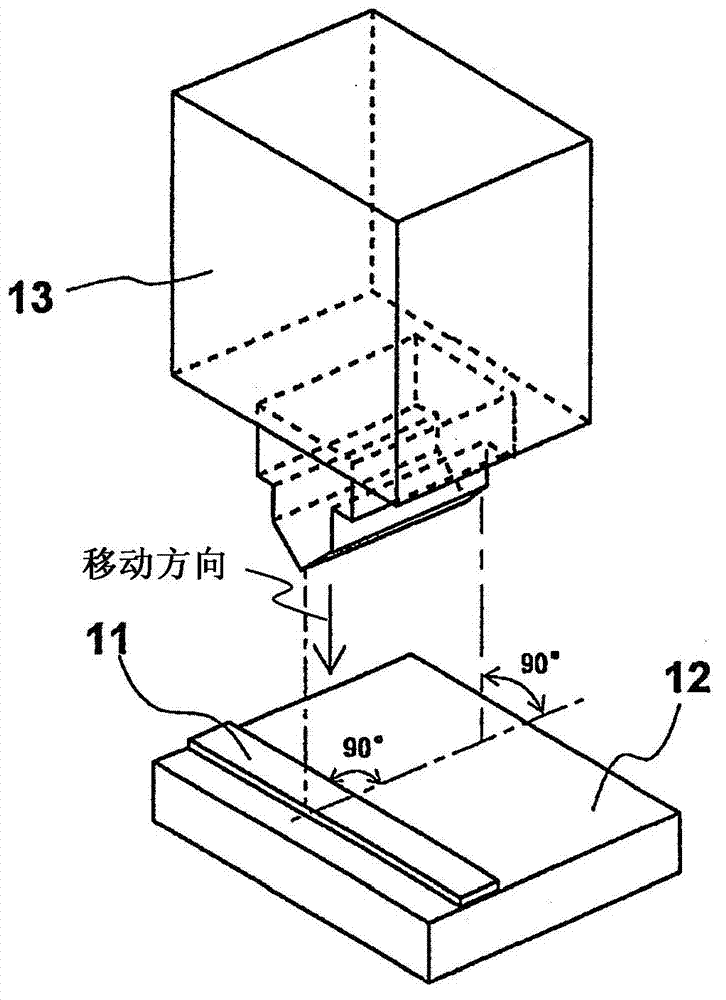

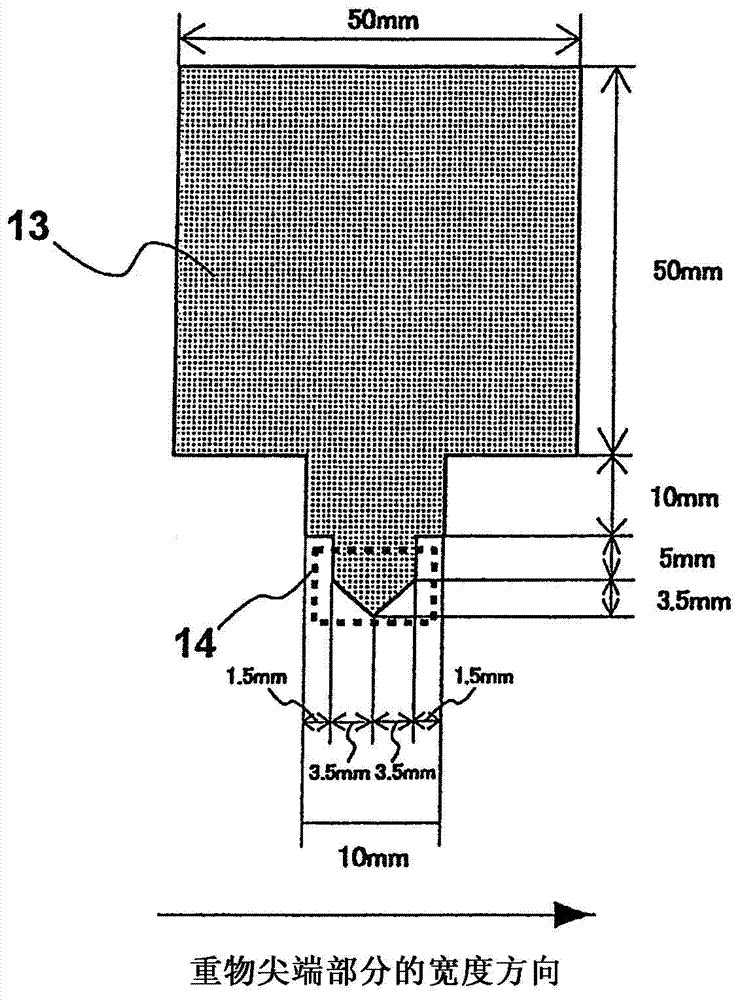

[0085] figure 2 is a schematic diagram (perspective view) illustrating the method of the dent test. exist figure 2 Among them, 13 represents heavy objects. image 3 is a front view (schematic) showing the weight used in the dent test, Figure 4 is a side view (schematic) showing the weight. exist im...

preparation example 1

[0236] Preparation example 1 (preparation of acrylic polymer)

[0237]In a reactor equipped with a condenser tube, a nitrogen inlet tube, a thermometer, a dropping funnel, and a stirrer, add 100 parts by weight of n-butyl acrylate, 2 parts by weight of acrylic acid, 8 parts by weight of vinyl acetate, 0.1 parts by weight of 2-hydroxyethyl acrylate and 0.2 parts by weight of azobisisobutyronitrile (AIBN) (10 hour half-life temperature: 65°C). Next, after nitrogen reflux at room temperature for 1 hour, the temperature was raised, and a polymerization reaction was performed at 58° C. for 6 hours as a main reaction. Then the temperature was further raised, and the first aging reaction was performed at 65° C. for 2 hours. The temperature was raised again, and a second aging reaction was performed at 72° C. for 2 hours. Then, the reaction mixture was cooled to obtain an acrylic polymer solution (referred to as "acrylic polymer solution A"). The acrylic polymer in the acrylic pol...

preparation example 2

[0238] Preparation example 2 (preparation of acrylic polymer)

[0239] Except replacing the solvent (organic solvent) with a mixed solvent of toluene and ethyl acetate (toluene / ethyl acetate=8 / 2 weight ratio) and performing the main reaction at 56° C. for 6 hours, followed by the first reaction at 64° C. The secondary aging reaction was carried out for 2 hours, the temperature was increased, and the second aging reaction was carried out at 73°C for 3 hours, in the same manner as in Preparation Example 1, an acrylic polymer solution (referred to as "acrylic polymer solution") was obtained. B"). The weight-average molecular weight of the acrylic polymer in the acrylic polymer solution B (referred to as "acrylic polymer B") was 550,000, the weight-average molecular weight / number-average molecular weight ratio was 6.2, and the molecular weight among all the polymers was The ratio (content) of the polymer of 100,000 or less was 22% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com