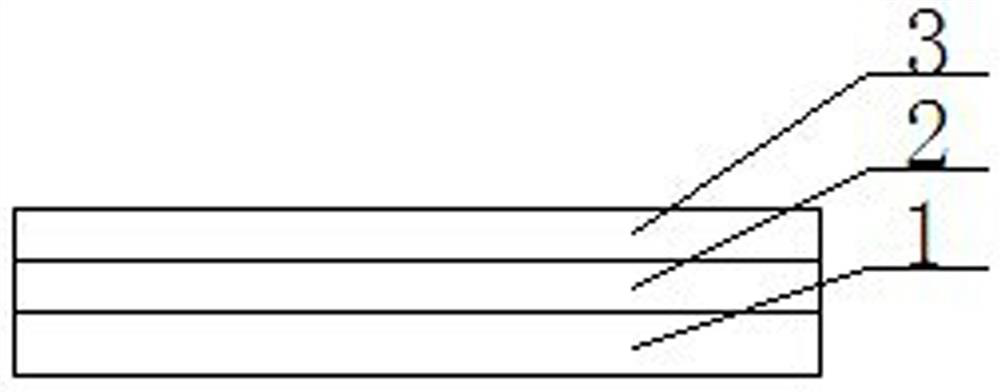

A process-free heat-sensitive plate for on-machine development with a nano-micron structure protective layer

A protective layer, nano-micron technology, applied in the photo-engraving process of the pattern surface, photosensitive materials for opto-mechanical equipment, printing plates, etc. Problems such as poor permeability, to achieve the effect of high print resistance and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

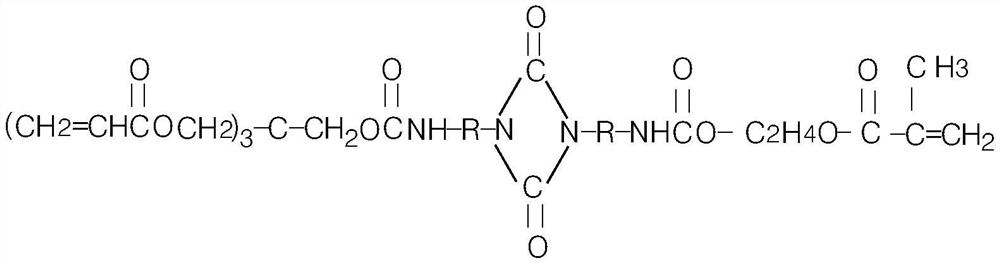

Method used

Image

Examples

Synthetic example 1

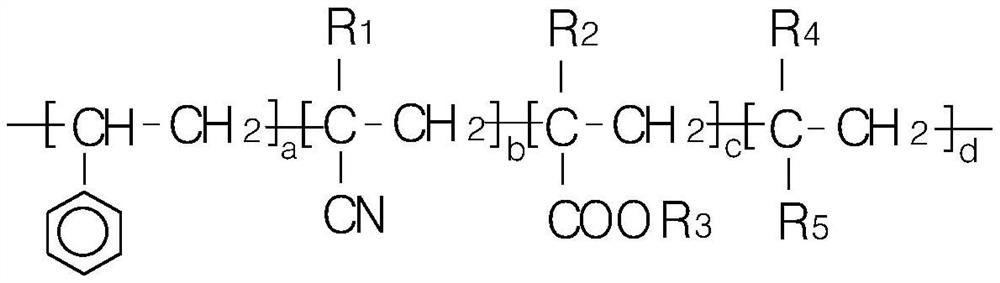

[0096] Synthesis Example 1 (Emulsion Particle P1)

[0097] Add 300g isopropanol, 100g deionized water, 10g (10% by weight) example compound A1 (n is 60) to a 1000ml four-necked flask with temperature-controlled heating, mechanical stirring, condensation reflux and nitrogen protection device, heat and stir evenly , 70g (70% by weight) St (styrene), 10g (10% by weight) AN (acrylonitrile), 10g (10% by weight) HEMA hydroxyethyl methacrylate and 0.7g AIBN (azo bisisobutyronitrile), the dropwise addition time was 1 hour, and 0.3 g of AIBN (azobisisobutyronitrile) was added after the reaction for 7.5 hours, and the reaction was continued for another 12 hours.

[0098] The solid content was 25%, the GPC molecular weight was 93600, and the particle diameter was 200 nm.

Synthetic example 2

[0099] Synthesis Example 2 (Emulsion Particle P2)

[0100] Add 357g isopropanol, 119g deionized water, 10g (10% by weight) example compound A2 (n is 50) to a 1000ml four-necked flask with temperature-controlled heating, mechanical stirring, condensation reflux and nitrogen protection device, heat and stir evenly , 60g (60% by weight) St (styrene), 20g (20% by weight) AN (acrylonitrile), 10g (10% by weight) HEMA hydroxyethyl methacrylate and 0.7g AIBN (azo Diisobutyronitrile), the dropwise addition time was 1.5 hours, and 0.3 g of AIBN (azobisisobutyronitrile) was added after the reaction for 7.5 hours, and the reaction was continued for another 12 hours.

[0101] The solids content (solute / solvent) was 21%, the GPC molecular weight was 76800, and the particle diameter was 150 nm.

Synthetic example 3

[0102] Synthesis Example 3 (Emulsion Particle P3)

[0103] Add 417g isopropanol, 139g deionized water, 10g (10% by weight) example compound A1 (n is 40) to a 1000ml four-necked flask with temperature-controlled heating, mechanical stirring, condensation reflux and nitrogen protection device, heat and stir evenly , 50g (50% by weight) St (styrene), 30g (30% by weight) AN (acrylonitrile), 10g (10% by weight) HEA hydroxyethyl acrylate and 0.7g AIBN (azodiisopropyl acrylate) were added dropwise at 60°C Butyronitrile), the dropwise addition time was 2.0 hours, and 0.3 g of AIBN (azobisisobutyronitrile) was added after the reaction for 7.5 hours, and the reaction was continued for another 12 hours.

[0104] The solids content was 18%, the GPC molecular weight was 63700, and the particle diameter was 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com