Method for building grouted overlapping assembly type reinforced concrete shear wall structure

A reinforced concrete and shear wall technology, applied in the field of construction, can solve the problems of low industrialization, low construction efficiency, difficult quality assurance, and high construction costs, and achieve the effects of reducing construction costs, improving quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

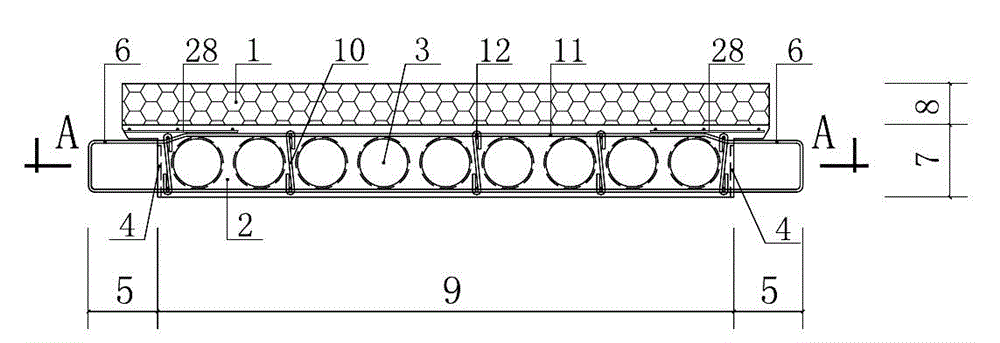

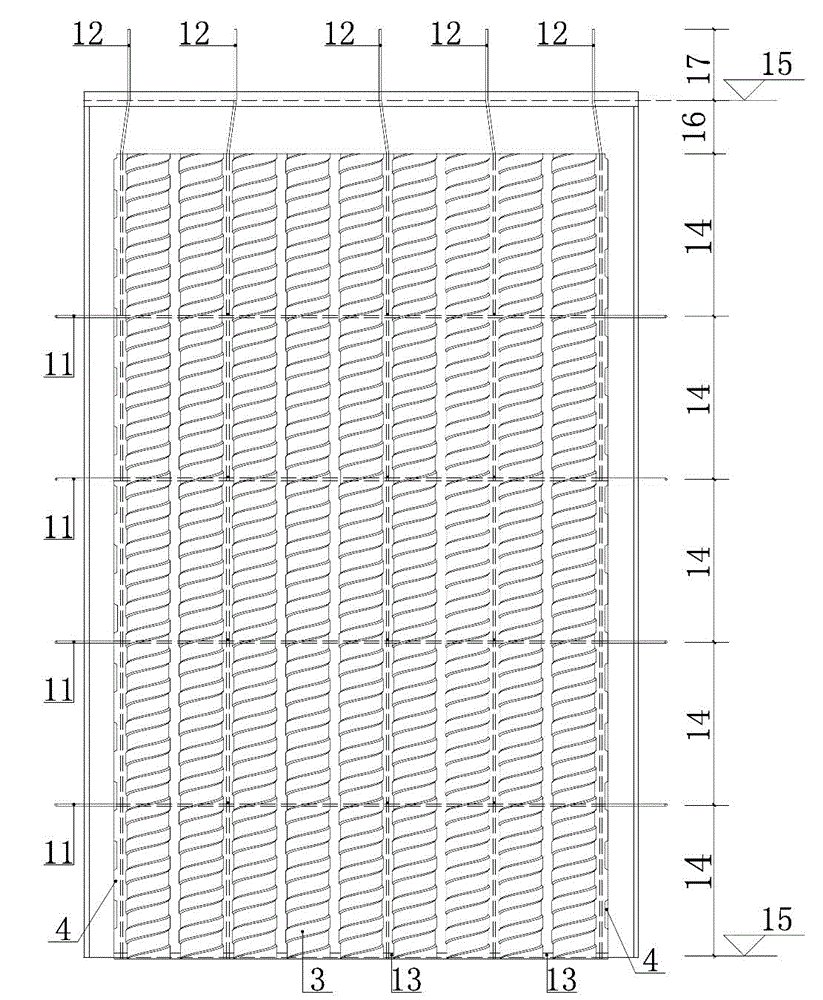

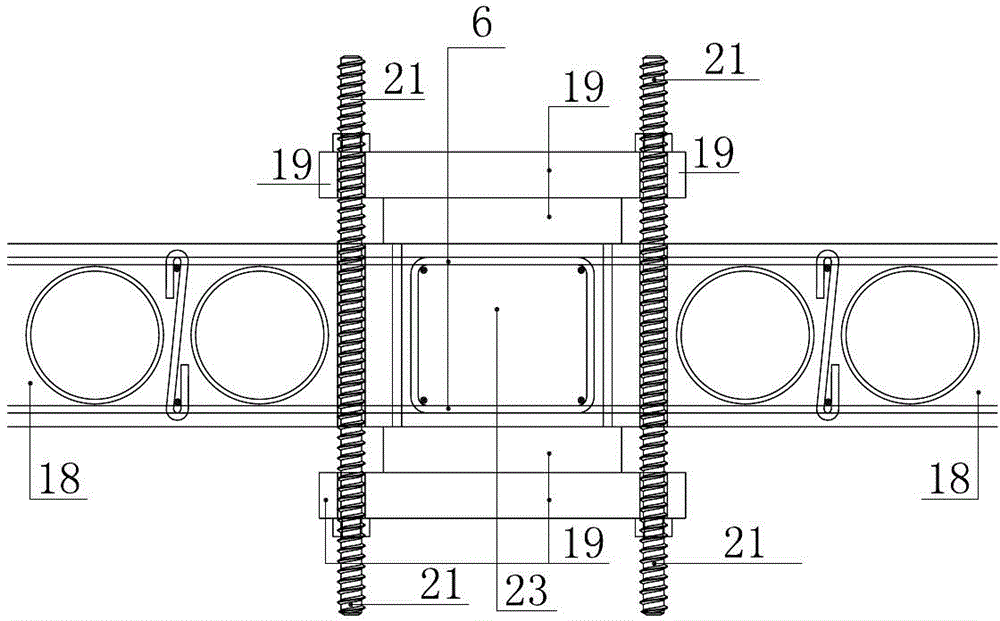

[0046] The split design of the structural member of the present invention is as attached figure 1 As shown, the factory prefabricated concrete hollow shear wall element is used, and a small amount of cast-in-place concrete is used to connect the nodes (attached Figure 4 , 5 , 6, 7, 8, 9), and the method of pouring laminated concrete on the hollow part of the precast concrete hollow shear wall component unit to realize the overall connection of each prefabricated component unit and become the overall structure of the shear wall to achieve Equivalent to the purpose of cast-in-place concrete structure, the specific method is:

[0047] According to the splitting principle of the technical solution of the present invention, the overall structure that has been designed is split into a plurality of components, which are respectively component a, component b, component c, component d, component e, ..., component n, and the above components have a-b , b-c, c-d, d-e, e-n and other m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com