Pan-fired green tea automatic production line control system

An automated production line and control system technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as rough control, rising labor prices, and high labor intensity of workers, so as to ensure continuity and reduce labor demand , The effect of continuous production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The following is an introduction to the control system of the automatic production line of fried green tea:

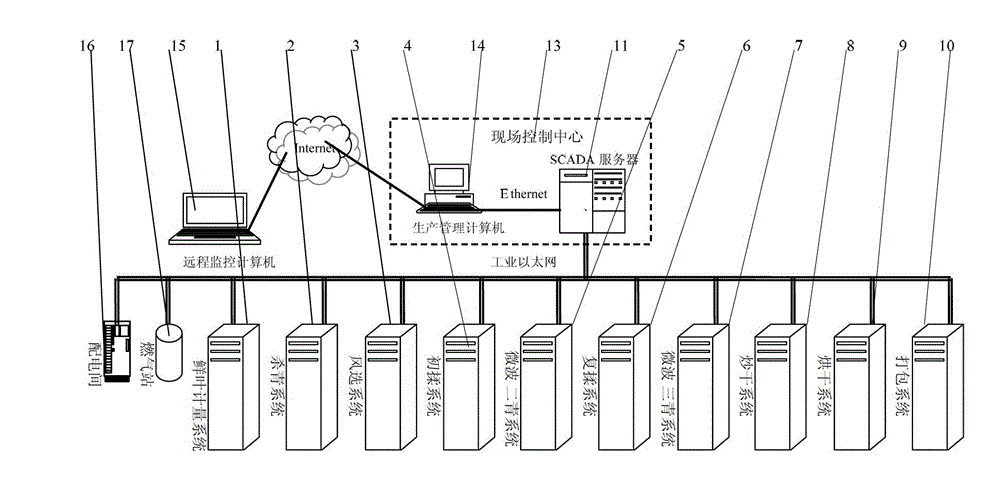

[0039] 1. If figure 1 As shown, with SCADA (data acquisition and monitoring) server as the hub, it includes distributed data acquisition system, process monitoring and management system and data communication network:

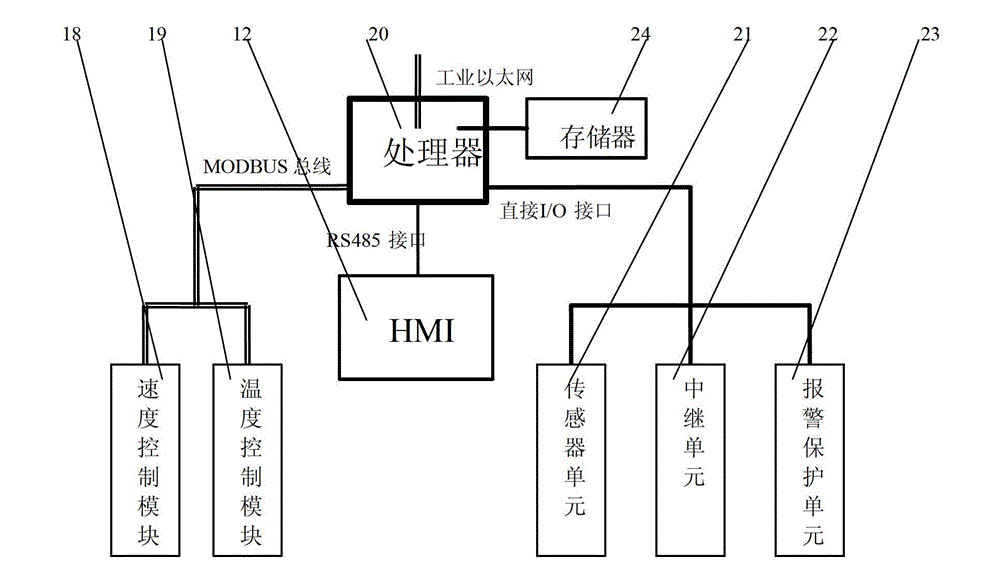

[0040] The distributed data acquisition system, that is, the lower computer system, consists of a core controller, a human-computer interaction touch screen, sensors and control relays. It is responsible for collecting field device information, uploading it to the SCADA server, and directly controlling the field devices. According to the production process of roasted green tea, the design includes fresh leaf metering system, greening system, winnowing system, primary kneading system, microwave second greening system, re-kneading system, microwave three greening system, frying system, drying system, packaging system, etc. 10 lower computer system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com