Palladium ruthenium/multiwall carbon nanotube (PdRu/MWNT) catalyst and preparation method thereof

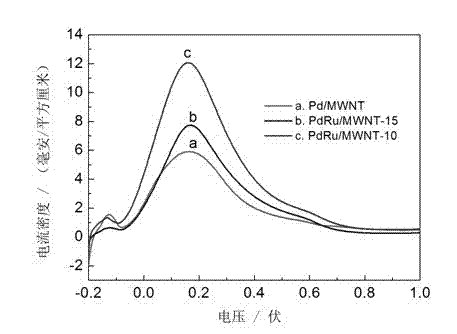

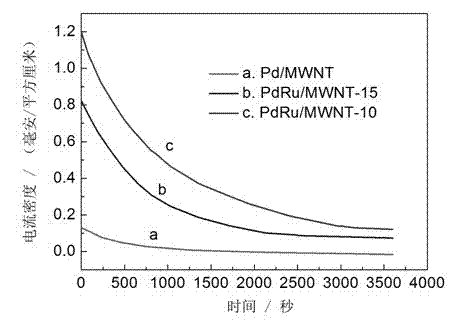

A technology of multi-walled carbon nanotubes and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. ability and other issues, to achieve the effect of stabilizing electrocatalytic activity, improving electrochemical activity, improving electrocatalytic activity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

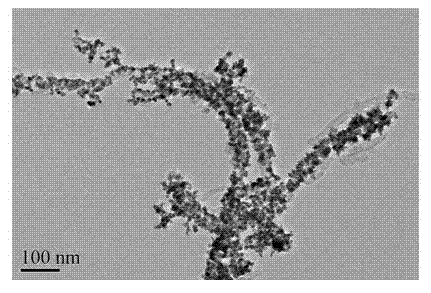

Image

Examples

Embodiment 1

[0020] 1) Put the carbon nanotubes in the mixed acid of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid and concentrated nitric acid in the mixed acid is 3:1, react with ultrasonic at a constant temperature of 80 °C for 6 h, wash and filter with deionized water, until The filtrate has a neutral pH value and is dried at a low temperature to obtain functional grouped multi-walled carbon nanotube materials;

[0021] 2) Weigh palladium chloride (PdCl 2 ) was dispersed in deionized water, and ultrasonicated at a constant temperature of 50°C for 20 min to obtain uniform PdCl 2 aqueous solution, wherein the concentration of palladium (Pd) is 0.05mg / mL;

[0022] 3) Weigh ruthenium trichloride (RuCl 3 ) was dispersed in deionized water to obtain a uniform ruthenium trichloride aqueous solution, wherein the ruthenium ion concentration was 0.05 mg / L;

[0023] 4) Take 20 mg of the multi-walled carbon nanotube material prepared in ...

Embodiment 2

[0026] 1) Put the carbon nanotubes in the mixed acid of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid and concentrated nitric acid in the mixed acid is 3:1, ultrasonic reaction at a constant temperature of 90 °C for 7 h, washing and filtering with deionized water, until The filtrate has a neutral pH value and is dried at a low temperature to obtain functional grouped multi-walled carbon nanotube materials;

[0027] 2) Weigh palladium chloride (PdCl 2 ) was dispersed in deionized water, and ultrasonicated at a constant temperature of 50°C for 25 min to obtain uniform PdCl 2 aqueous solution, wherein the concentration of palladium (Pd) is 0.1 mg / mL;

[0028] 3) Weigh ruthenium trichloride (RuCl 3 ) was dispersed in deionized water to obtain a uniform ruthenium trichloride aqueous solution, wherein the ruthenium ion concentration was 0.1 mg / L;

[0029] 4) Take 10 mg of the multi-walled carbon nanotube material prepared ...

example example 3

[0032] 1) Put the carbon nanotubes in the mixed acid of concentrated sulfuric acid and concentrated nitric acid, the volume ratio of concentrated sulfuric acid and concentrated nitric acid in the mixed acid is 3:1, 100 °C constant temperature ultrasonic reaction for 8 h, washing and filtering with deionized water, until The filtrate has a neutral pH value and is dried at a low temperature to obtain functional grouped multi-walled carbon nanotube materials;

[0033] 2) Weigh palladium chloride (PdCl 2 ) was dispersed in deionized water, and ultrasonicated at a constant temperature of 50°C for 25 min to obtain uniform PdCl 2 aqueous solution, wherein the concentration of palladium (Pd) is 0.1 mg / mL;

[0034] 3) Weigh ruthenium trichloride (RuCl 3 ) was dispersed in deionized water to obtain a uniform ruthenium trichloride aqueous solution, wherein the ruthenium ion concentration was 0.05 mg / L;

[0035] 4) Take 15 mg of the multi-walled carbon nanotube material prepared in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com