Column-slot combined technology for grading calcium collophanite

A combined process and collophosite technology, applied in flotation, solid separation, etc., can solve problems affecting normal production, pipeline blockage, etc., achieve the effects of reducing chemical consumption, easy regulation, and prolonging flotation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

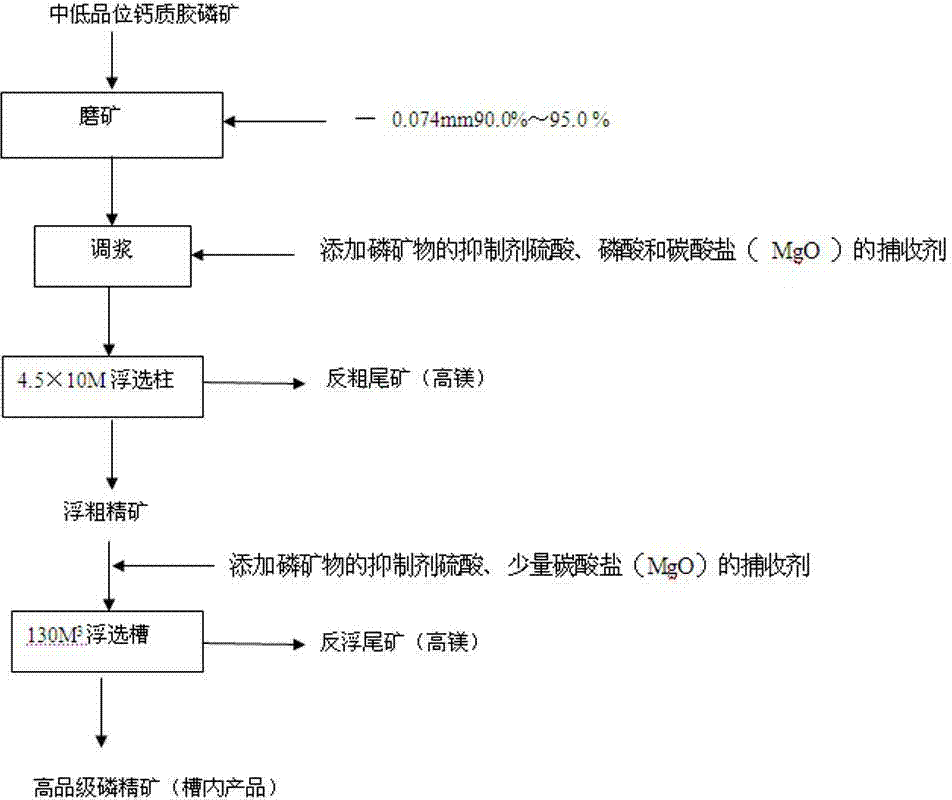

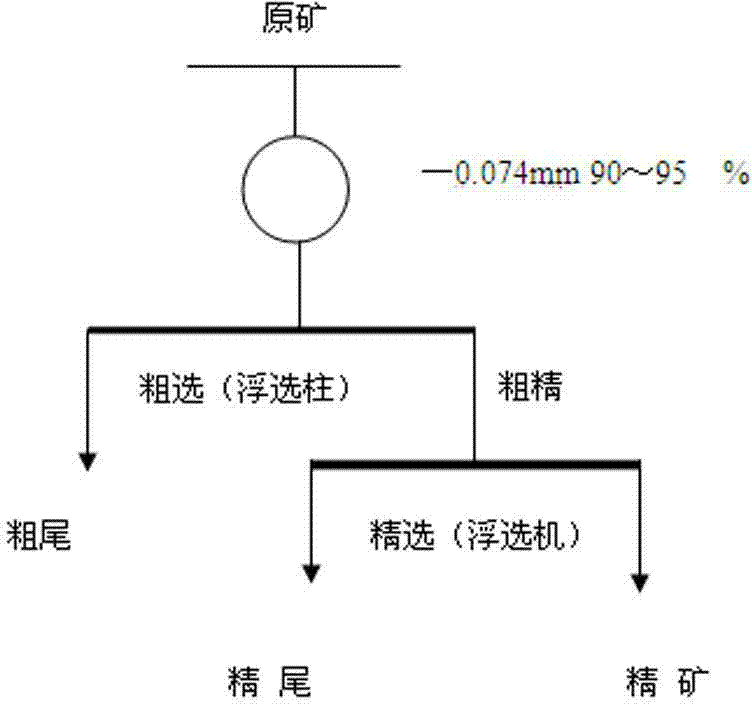

Method used

Image

Examples

Embodiment 1

[0026] A calcareous colloid ore mining area in Yunnan, according to the above-mentioned process plan of the present invention, at room temperature, add YP4: 20.60Kg / t, YP3: 4.5 Kg / t, YP2-3: 3.0 Kg / t, and reverse float and concentrate Use 130M 3 Flotation machine, select and add YP4: 5.5Kg / t, YP2-3: 1.5 Kg / t; the following indicators can be obtained, raw ore P 2 o 5 Content 22.0wt%, MgO content 5.40wt%, concentrate P 2 o 5 Content 30.10wt%, MgO content 0.80wt% , Yield 61.61% , The recovery rate is 84.30%, and the magnesium removal rate is 90.87%.

Embodiment 2

[0028] A calcareous colloid ore mining area mine sample, according to the above-mentioned process plan of the present invention, at room temperature, add YP4: 19.45Kg / t, YP3: 4.0 Kg / t, YP2-3: 2.5Kg / t, reverse flotation concentration using 130M 3 Flotation machine, select and add YP4: 5.0Kg / t, YP2-3: 1.3 Kg / t; the following indicators can be obtained, raw ore P 2 o 5 Content 24.0wt%, MgO content 4.50wt%, concentrate P 2 o 5 Content 30.50wt%, MgO content 0.74wt% , Yield 68.60% , The recovery rate was 87.18%, and the magnesium removal rate was 88.72%.

Embodiment 3

[0030] A calcareous colloid ore mining area mine sample, according to the above-mentioned process plan of the present invention, at room temperature, add YP4: 25.45Kg / t, YP3: 4.8 Kg / t, YP2-3: 3.0Kg / t, reverse flotation concentration using 130M 3 Flotation machine, select and add YP4: 6.5Kg / t, YP2-3: 1.8 Kg / t; the following indicators can be obtained, raw ore P 2 o 5 Content 20.15wt%, MgO content 6.13wt%, concentrate P 2 o 5 Content 29.64wt%, MgO content 0.65wt% , Yield 55.84% , The recovery rate was 82.14%, and the magnesium removal rate was 94.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com