Construction method of a large-diameter gravel pile

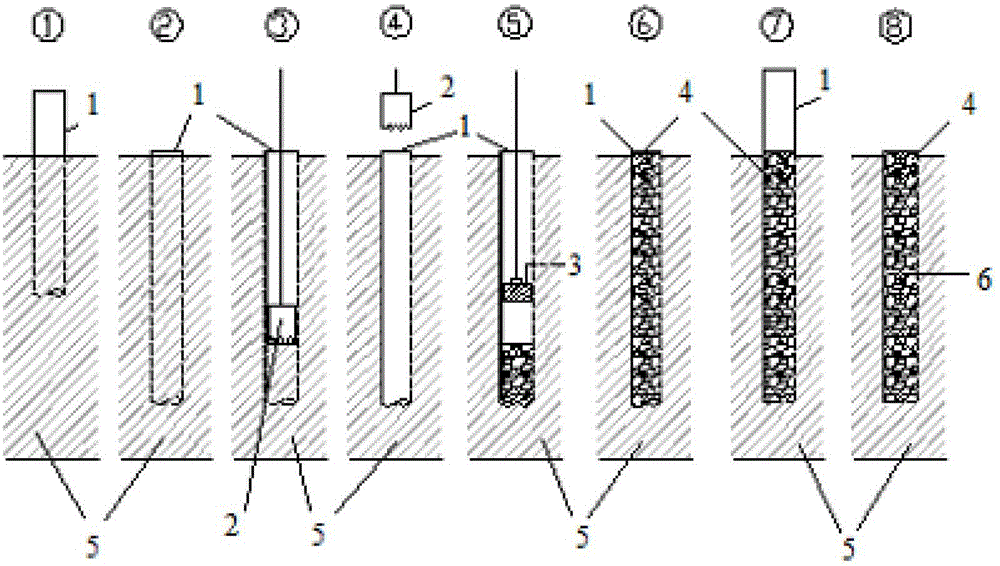

A construction method and large-diameter technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of restricting the popularization and application of gravel piles, low bearing capacity of small-diameter piles, and difficulty in constructing large-diameter piles, etc. The effect of controllable pile quality, low construction difficulty and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A petrochemical storage land is a large-scale land reclamation site, and the surface layer is backfilled with mountain stone filler with a thickness of 5-8m and a particle size of up to 80cm. There are silt or silty clay layers with a thickness of 20-30m distributed below the fill layer. According to the survey report, the silt-like soft soil layer is an under-consolidated soil layer. After calculation, the settlement after the site construction reaches 1-2m, and the consolidation period of 20-30 years is required for the consolidation degree to reach more than 90%, which is far from enough To meet the needs of engineering construction, effective foundation treatment measures must be adopted before it can be used as construction land. The proposed structures on the site are steel storage tanks with diameters ranging from 40 to 60 m, and the foundation pressure is 220 to 250 kPa. The bearing capacity and settlement deformation of the site foundation cannot meet the founda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com