High-efficiency and low-emission novel composite thermodynamic cycle control method for engine

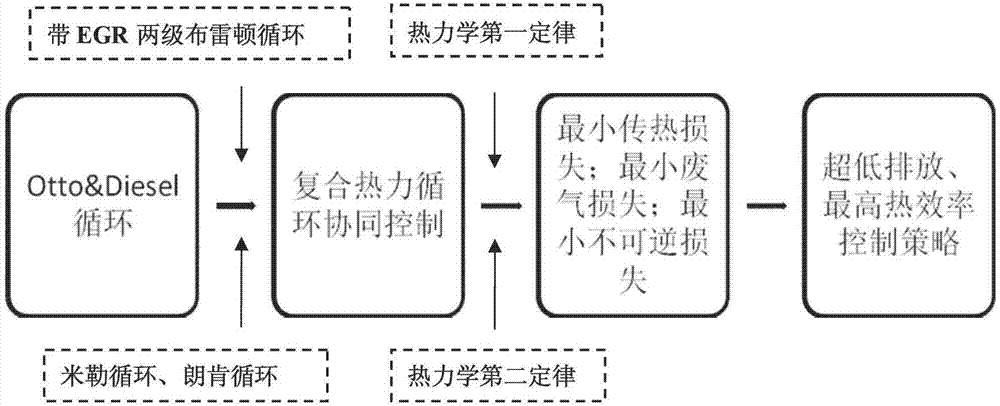

A thermodynamic cycle and control method technology, applied in engine control, combustion engine, machine/engine, etc., can solve the problems of intensity mixing time, low chemical reaction rate, high thermal efficiency, thermal efficiency and harmful emission control, etc., to improve transient response characteristics , increase the power per liter and low-speed torque, and reduce the effect of combustion heat transfer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

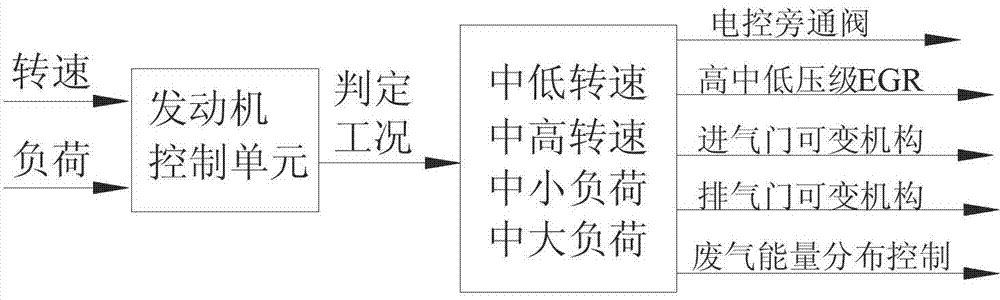

[0027] (1) The control unit reads the speed signal of the sensor installed on the crankshaft of the engine and the engine load signal of the sensor installed on the accelerator pedal, and judges the load and speed conditions of the engine operation according to the speed signal and engine load signal. ;

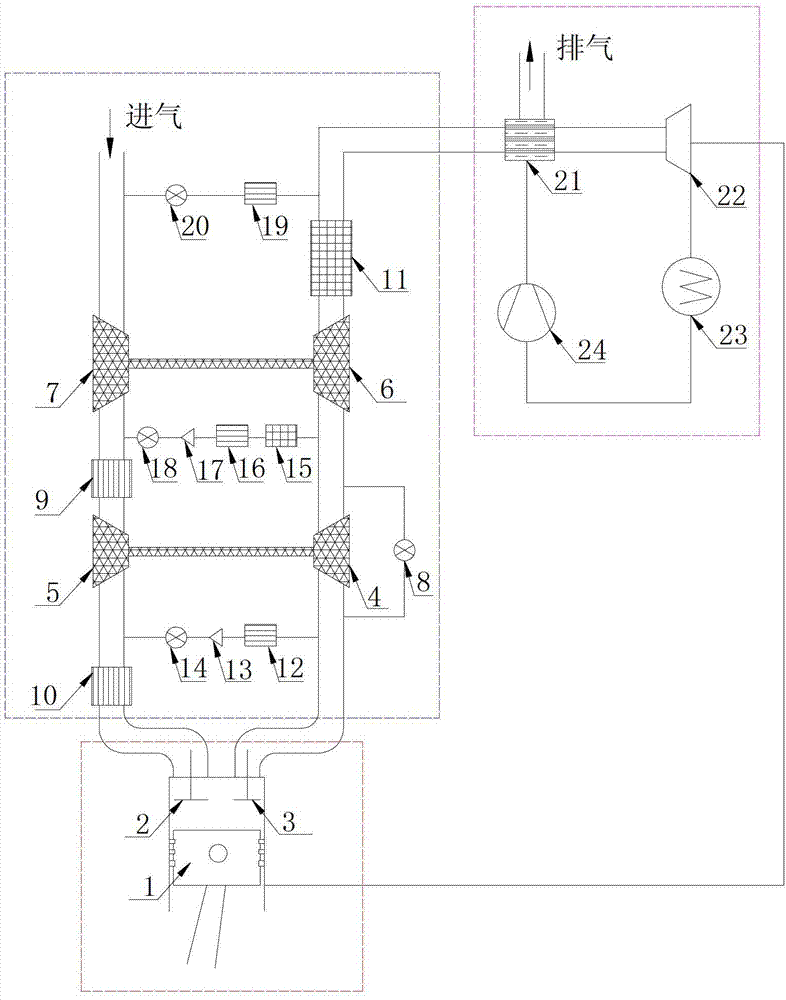

[0028] (2) If the judgment result in step (1) is a low-to-medium speed operating condition, the control unit will send a closing signal to the electronically controlled bypass valve installed on the engine exhaust bypass pipe, and the exhaust gas will pass through the high-pressure stage. The turbine and the low-pressure stage turbine expand in sequence. At this time, the intermediate-pressure exhaust gas recirculation valve and the low-pressure exhaust gas recirculation valve are opened, and part of the exhaust gas flows through the second particulate trap, the intermediate-pressure exhaust gas recirculation cooler, and the second The one-way valve and the medium-pressure exhau...

Embodiment 2

[0034] (1) The control unit reads the speed signal of the sensor installed on the crankshaft of the engine and the engine load signal of the sensor installed on the accelerator pedal, and judges the load and speed conditions of the engine operation according to the speed signal and engine load signal. ;

[0035] (2) If the judgment result in step (1) is a low-to-medium speed operating condition, the control unit will send a closing signal to the electronically controlled bypass valve installed on the engine exhaust bypass pipe, and the exhaust gas will pass through the high-pressure stage. The turbine and the low-pressure stage turbine expand in sequence. At this time, the intermediate-pressure exhaust gas recirculation valve and the low-pressure exhaust gas recirculation valve are opened, and part of the exhaust gas flows through the second particulate trap, the intermediate-pressure exhaust gas recirculation cooler, and the second The one-way valve and the medium-pressure exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com