Vehicle-mounted multi-degree of freedom numerical control hedge trimming machine

A hedge trimmer and a degree of freedom technology, applied in the field of hedge trimmers, can solve the problems of inconsistency in trimming height, low working efficiency of hedge trimmers, threats to personnel safety, etc. The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

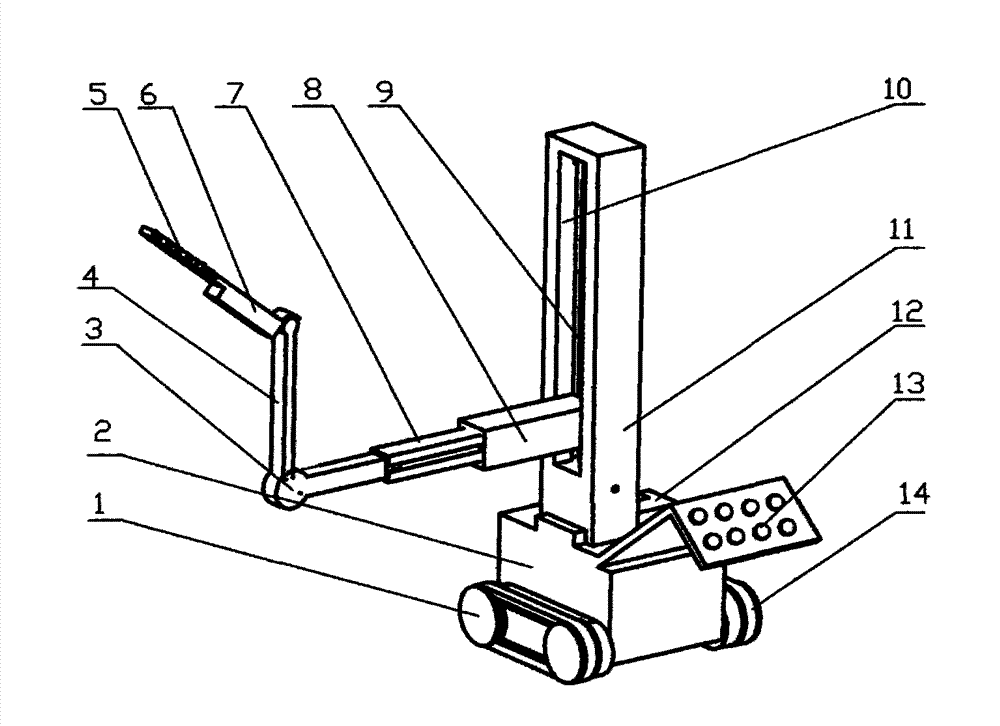

[0015] Such as figure 1 As shown, the present invention includes a load-bearing trolley 2 and a trimmer placed on the load-bearing trolley 2, and is characterized in that: the load-bearing trolley 2 is a small and simple car, and the load-bearing trolley 2 is provided with a wheel 1, a storage battery, a numerical control system and a console 13 and The base 12 that is used to install the trimmer; The trimmer includes a column 11, cross arm 8, pivoting arm 4, trimming motor, tool rest 6 and cutter 5, and the column 11 can move laterally on the base 12; One side of the column 11 has The chute 10 is equipped with a transmission screw 9; the cross arm 8 passes through the chute 10 and is installed on the transmission screw 9, and can move up and down in the chute 10; the cross arm 8 is provided with a telescopic rod 7; the telescopic rod 7 passes through the Rotating shaft 3 is connected with pivoting arm 4, and pivoting arm 4 can rotate up and down; The carrying trolley is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com