Preparation method of graphene covered silica gel

A technology of graphene wrapping and graphene, which is applied in chemical instruments and methods, silicon compounds, and other chemical processes, can solve the problems of long preparation cycle, low graphene bonding amount, and reduced adsorption amount, and achieve simple preparation methods Fast, high graphene content, good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of graphene-coated silica gel

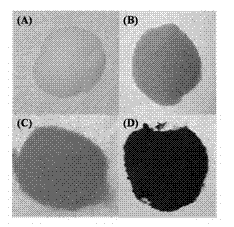

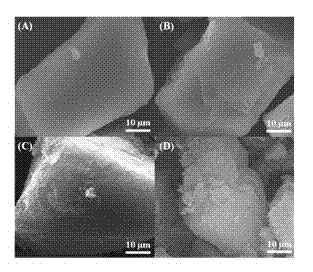

[0023] First prepare amino silica gel dispersion with a concentration of 7.0 g / mL and graphene oxide dispersion with a concentration of 2.0 g / mL, and then mix the two. After mixing, the concentrations of amino silica gel and graphene oxide are 3.5 g / mL and 1.0 g, respectively. / mL, stir the mixture for 2 h, put the mixture into the reaction kettle, react at 230 °C for 3 h, and use N,N-dimethylformamide to float the reaction product to remove the graphite not wrapped on the silica gel ene, to obtain graphene-wrapped silica gel D (such as figure 2 shown).

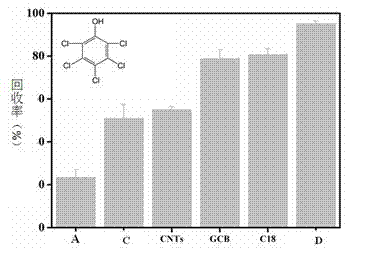

[0024] (2) Comparison of materials prepared by the present invention and materials prepared by prior art

[0025] In order to compare with the method of reducing graphene oxide-wrapped silica gel material in the prior art, free graphene oxide is removed before thermal reduction, only graphene oxide-wrapped silica gel is thermally reduced, and graphene-wrapped silica ge...

Embodiment 2

[0027] Preparation of graphene-coated silica gel

[0028] First prepare amino silica gel dispersion liquid with a concentration of 7.0 g / mL and graphene oxide dispersion liquid with a concentration of 1.0 g / mL, and then mix the two. The concentrations of amino silica gel and graphene oxide in the mixed liquid are 3.5 g / mL and 0.5 g / mL respectively. g / mL, stir the mixed solution for 2 h, put the mixed solution in a reaction kettle, react at 230 °C for 3 h, and use N,N-dimethylformamide to float the reaction product to remove the uncoated silica gel. Graphene, get graphene-coated silica gel.

Embodiment 3

[0030] Preparation of graphene-coated silica gel

[0031] Firstly, a dispersion of amino silica gel with a concentration of 7.0 g / mL and a dispersion of graphene oxide with a concentration of 5.0 g / mL were prepared, and then the two were mixed. After mixing, the concentrations of amino silica gel and graphene oxide were 3.5 g / mL and 2.5 g / mL, respectively, and the mixture was stirred for 1 h. The mixture was put into the reactor and reacted at 230 °C for 3 h. The reaction product is then floated with N,N-dimethylformamide to remove the graphene not wrapped on the silica gel to obtain the graphene-wrapped silica gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com