Attapulgite clay based adsorbing material and preparation method thereof

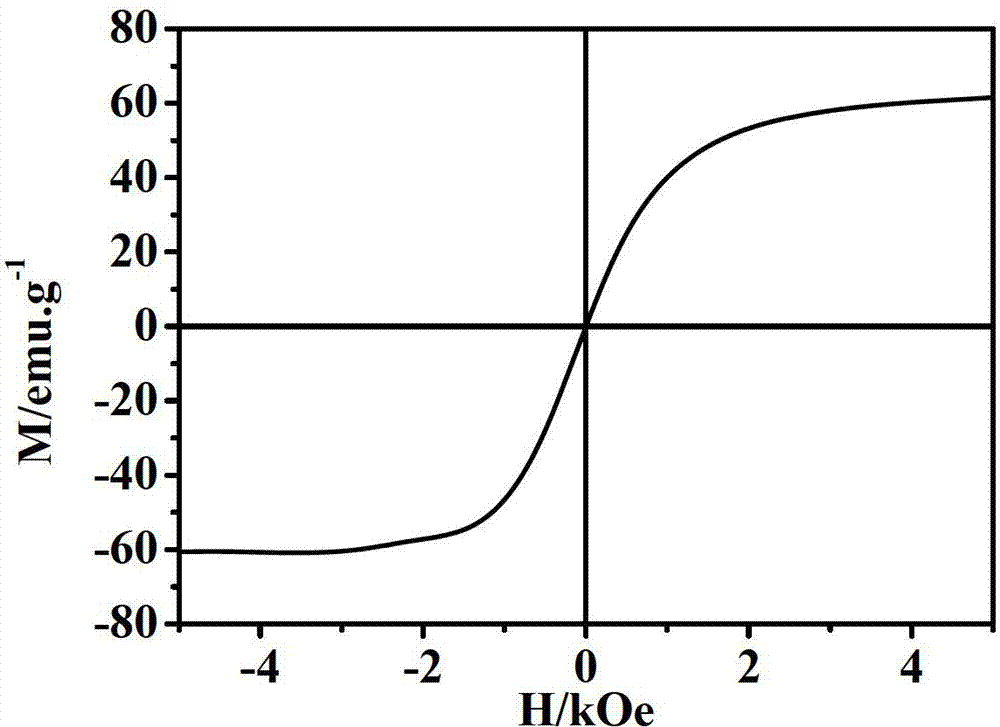

An adsorption material and attapulgite technology, which is applied in the field of attapulgite-based adsorption materials and its preparation, can solve problems such as separation and recovery difficulties, and achieve the effects of easy separation and recovery, excellent magnetic properties, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 2g NaOH into 25mL triethanolamine (TEG) solution, pass N 2 protection, heated to 100°C for 1h under magnetic stirring, and then cooled to 70°C to obtain brown-red NaOH / TEG solution;

[0032] (2) Disperse 1 g of attapulgite into 20 mL of TEG, ultrasonically disperse for 30 min, then add 4 mmol of polyacrylic acid (PAA, Mw=1800) and 2 mmol of FeCl 3 , through N 2 Protected, heated to 100°C under stirring, kept warm for 1h, continued to heat up to 210°C, then quickly injected 5mL NaOH / TEG solution, and kept the temperature for 30min to continue the reaction and then lowered to room temperature, the product was washed several times with ethanol and deionized water , and finally dispersed in 20 mL of deionized water to obtain surface carboxylated Fe 3 o 4 / attapulgite composite dispersion;

[0033] (3) 0.72g chitosan (molecular weight is 1.1×10 5 , the degree of deacetylation is 90%) was dissolved in 20mL mass concentration of 2% acetic acid aqueous solution, an...

Embodiment 2

[0039] (1) Add 5g NaOH to 25mL diethylene glycol (DEG) solution, pass N 2 protection, heated to 120°C for 0.5h under magnetic stirring, and then cooled to 60°C to obtain a brown-red NaOH / DEG solution;

[0040] (2) Disperse 1g of attapulgite into 30mL of DEG, ultrasonically disperse for 30min, then add 10mmol of polyacrylic acid (PAA, Mw=1800) and 8mmol of FeCl 3 , through N 2 Protected, heated to 120°C under stirring, kept warm for 0.5h, continued to heat up to 220°C, then quickly injected 3mL NaOH / DEG solution, and kept the temperature for 60min to continue the reaction and then lowered to room temperature, the product was washed with ethanol and deionized water for several times, and finally dispersed in 20mL deionized water to obtain surface carboxylated Fe 3 o 4 / attapulgite composite dispersion;

[0041] (3) 4.5g chitosan (molecular weight is 2.0×10 5 , the degree of deacetylation is 75%) was dissolved in 25 mL of 5% acetic acid aqueous solution, and then the chitosa...

Embodiment 3

[0047] (1) Add 3g NaOH to 25mL triethanolamine (TEG) solution, pass N 2 protection, heated to 110°C for 1h under magnetic stirring, and then cooled to 60°C to obtain a brown-red NaOH / TEG solution;

[0048] (2) Disperse 1g of attapulgite into 20mL of TEG, ultrasonically disperse for 30min, then add 4mmol of polyacrylic acid (PAA, Mw=2000) and 4mmol of FeCl 3 , through N 2 protection, heated to 110°C under stirring, kept warm for 0.5h, then continued to heat up to 230°C, then quickly injected 2mL NaOH / TEG solution, and kept the temperature for 2h to continue the reaction and then lowered to room temperature, the product was washed with ethanol and deionized water for several times, and finally dispersed in 20mL deionized water to obtain surface carboxylated Fe 3 o 4 / attapulgite composite dispersion;

[0049] (3) 1.0g chitosan (molecular weight is 2.0×10 5 , the degree of deacetylation is 90%) was dissolved in 30mL mass concentration of 3% acetic acid aqueous solution, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com