Tellurium-containing glass material and preparation method and application thereof

A glass material and paste technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as pollution and toxicity, and achieve the effect of strong chemical stability, high thermal stability, excellent performance and characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

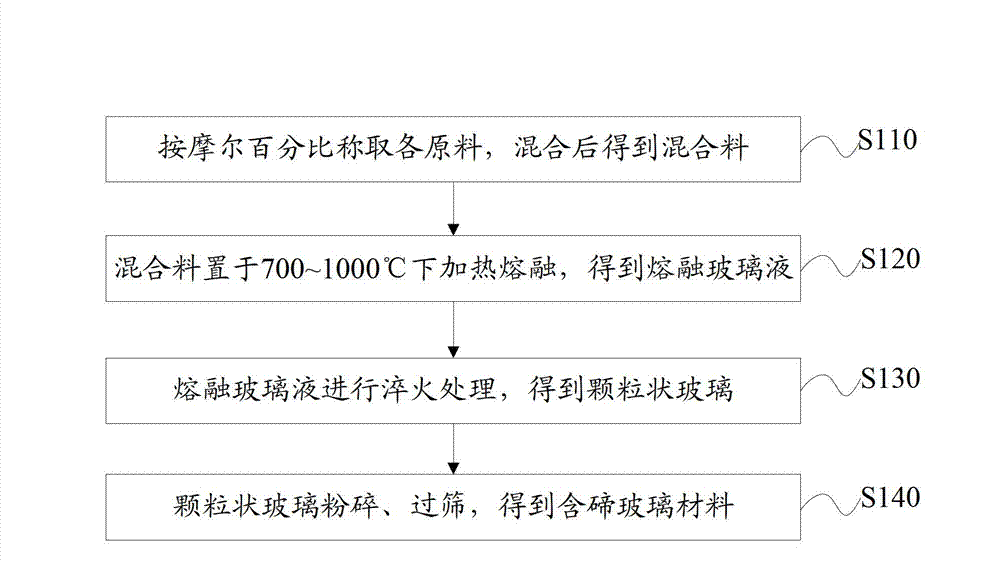

[0050] In addition, this embodiment also provides a method for preparing a tellurium-containing glass material, such as figure 1 shown, including the following steps:

[0051] Step S110, weighing each raw material according to the following mole percentages, and mixing to obtain a mixture,

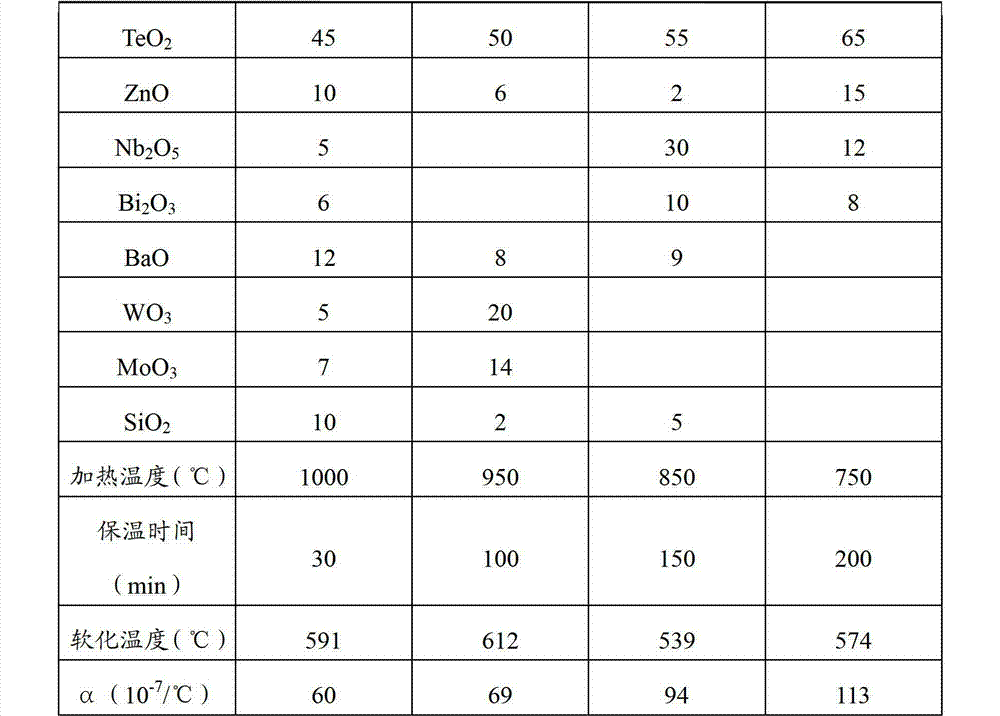

[0052] TeO 2 0~70%;

[0053] ZnO 2~25%;

[0054] Nb 2 o 5 0~30%;

[0055] Bi 2 o 3 0~25%;

[0056] BaO 0~20%;

[0057] WO 3 0~30%;

[0058] MoO 3 0~20%; and

[0059] SiO 2 0~25%.

[0060] Step S 120, heat and melt the mixture at 700-1000° C. to obtain molten glass.

[0061] Step S130, quenching the molten glass to obtain granular glass.

[0062] Among them, the quenching treatment is water quenching.

[0063] In step S140, the granular glass is ball-milled and sieved, and the collected glass powder is the glass material.

[0064] Wherein, the mesh size of the molecular sieve used in the sieving process is greater than 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com