Cabazitaxel crystal and preparation method thereof

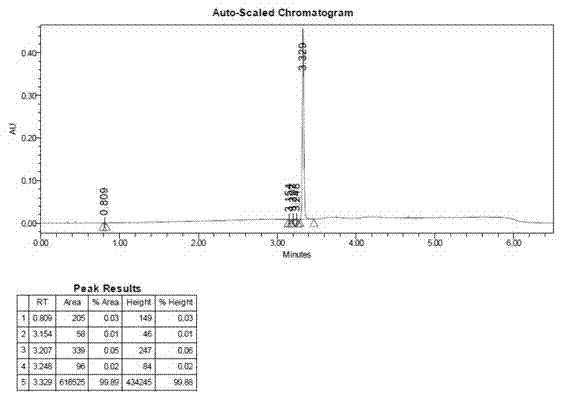

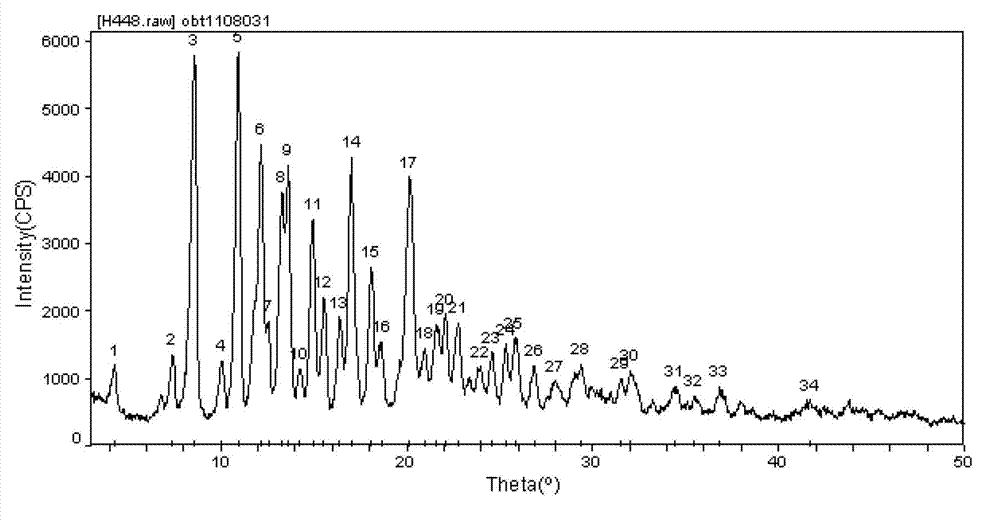

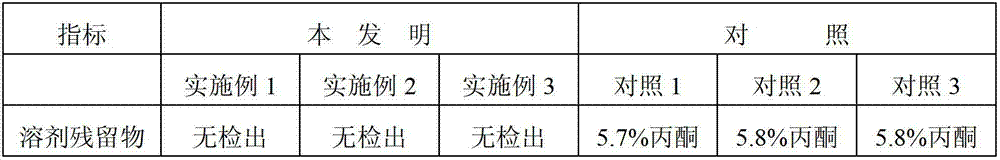

A technology of docetaxel and dimethoxy, which is applied in the field of cabazitaxel crystals and its preparation, can solve problems such as complex process, harsh reaction conditions, and influence on the purity of cabazitaxel, and achieve improved reaction efficiency and good purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Dissolve 4g of Cabazitaxel powder in 100ml of acetonitrile (heated to 30°C), then slowly add the resulting solution dropwise (about 20 minutes) into 1300ml of distilled water (frozen to 0-3°C, with a certain stirring speed), drop Stirring was continued for 30 minutes after addition, and white powder was obtained by suction filtration.

[0032] 2. The obtained white powder was dried under reduced pressure (vacuum 10-20 Pa) at room temperature for 48 hours to obtain 3.7 g of white powder.

[0033] 3. Dissolve 3.7g of the white powder obtained in operation 2 in 100ml of acetonitrile (heated to 30°C), then slowly add the resulting solution dropwise (about 20min) to 1300ml of distilled water (frozen to 0-3°C, with a certain stirring speed) After the dropwise addition, continue to stir for 30 minutes, and filter with suction to obtain a white powder.

[0034] 4. The resulting white powder was dried under reduced pressure (vacuum 10-20 Pa) at room temperature for 48 hours ...

Embodiment 2

[0036] 1. Dissolve 40g of Cabazitaxel powder in 1L of acetonitrile (heated to 30°C), then slowly add the resulting solution dropwise (about 2h) to 13L of distilled water (frozen to 0-3°C, with a certain stirring speed) while stirring , continued to stir for 30 min after the dropwise addition, and filtered with suction to obtain a white powder.

[0037] 2. The obtained white powder was dried under reduced pressure (vacuum 10-20 Pa) at room temperature for 48 hours to obtain 37.4 g of white powder.

[0038] 3. Dissolve 37.4g of the white powder obtained in operation 2 in 1L of acetonitrile (heated to 30°C), then slowly add the resulting solution dropwise (about 2h) to 13L of distilled water (frozen to 0-3°C, stirring regularly) speed), continue to stir for 30 minutes after the dropwise addition, and filter with suction to obtain a white powder.

[0039]4. The obtained powder was dried under reduced pressure (vacuum 10-20 Pa) at room temperature for 48 hours to obtain 35.8 g of ...

Embodiment 3

[0041] 1. Dissolve 80g of Cabazitaxel powder in 2L of acetonitrile (heated to 30°C), then slowly add the resulting solution dropwise (about 3h) to 26L of distilled water (frozen to 0-3°C, with a certain stirring speed) while stirring , continued to stir for 30 min after the dropwise addition, and filtered with suction to obtain a white powder.

[0042] 2. The obtained white powder was dried under reduced pressure (vacuum 10-20 Pa) at room temperature for 48 hours to obtain 75.1 g of white powder.

[0043] 3. Dissolve 75.1g of the white powder obtained in operation 2 in 2L of acetonitrile (heated to 30°C), then slowly add the resulting solution dropwise (for about 3 hours) to 26L of distilled water (frozen to 0-3°C, stirring regularly) speed), continue to stir for 30 minutes after the dropwise addition, and filter with suction to obtain a white powder.

[0044] 4. The resulting white powder was dried under reduced pressure (vacuum 10-20 Pa) at room temperature for 48 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com