Anti-corrosion and high-gloss paint and preparation method and use thereof

A high-gloss, coating technology, applied in the direction of anti-corrosion coatings, coatings, devices for coating liquids on the surface, etc., can solve the problems of increasing the conductivity of the paint film without considering the direct effect, and achieve good chemical stability and rough surface , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

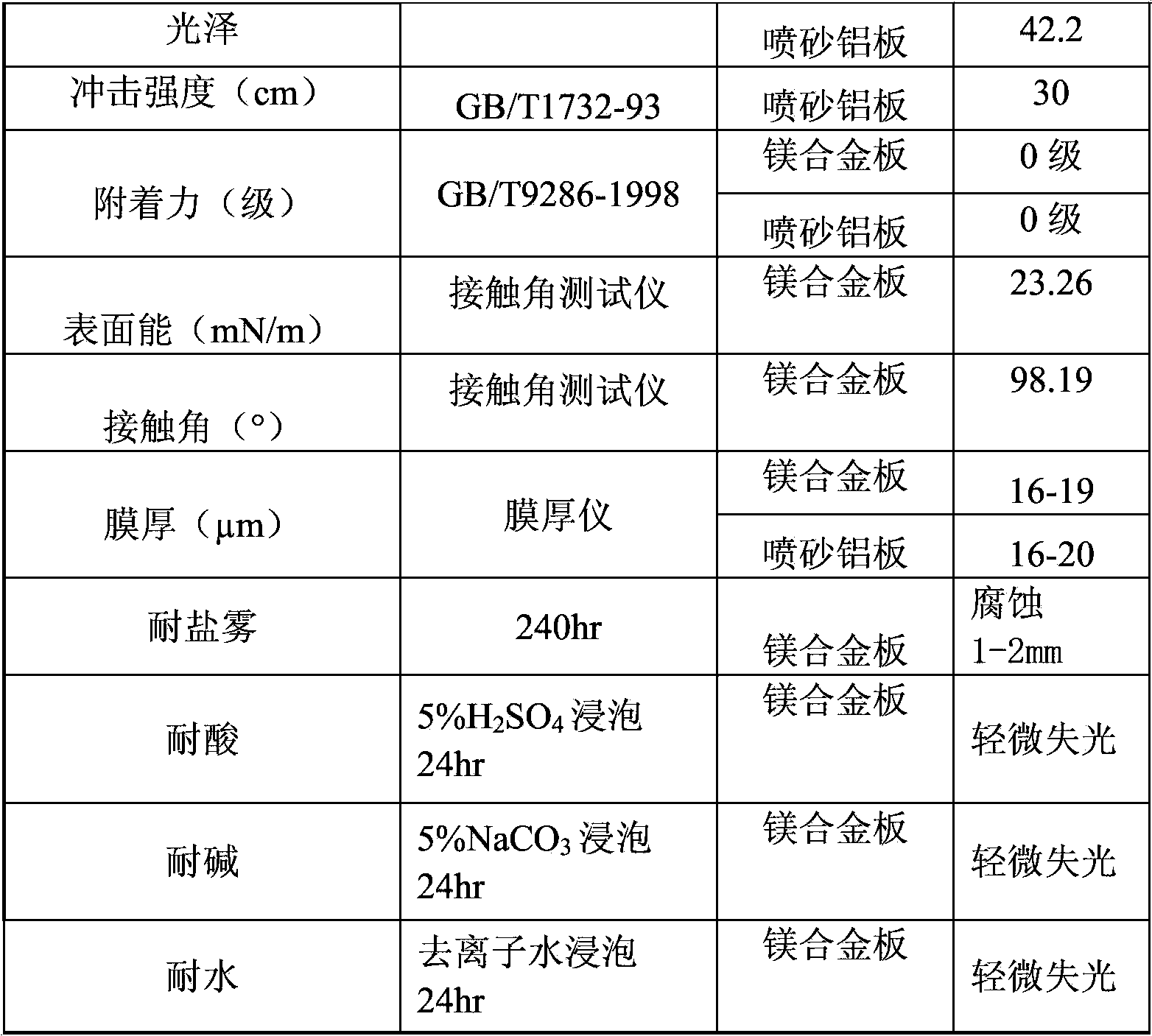

Examples

Embodiment 1

[0042] An anti-corrosion and high-gloss paint, which comprises a base paint and a silicone resin, the volume ratio of the base paint and the silicone resin is 1:0.5.

[0043] The invention relates to a preparation method of an anti-corrosion and high-gloss coating. After mixing a basic coating and a silicone resin, the anti-corrosion and high-gloss coating is obtained.

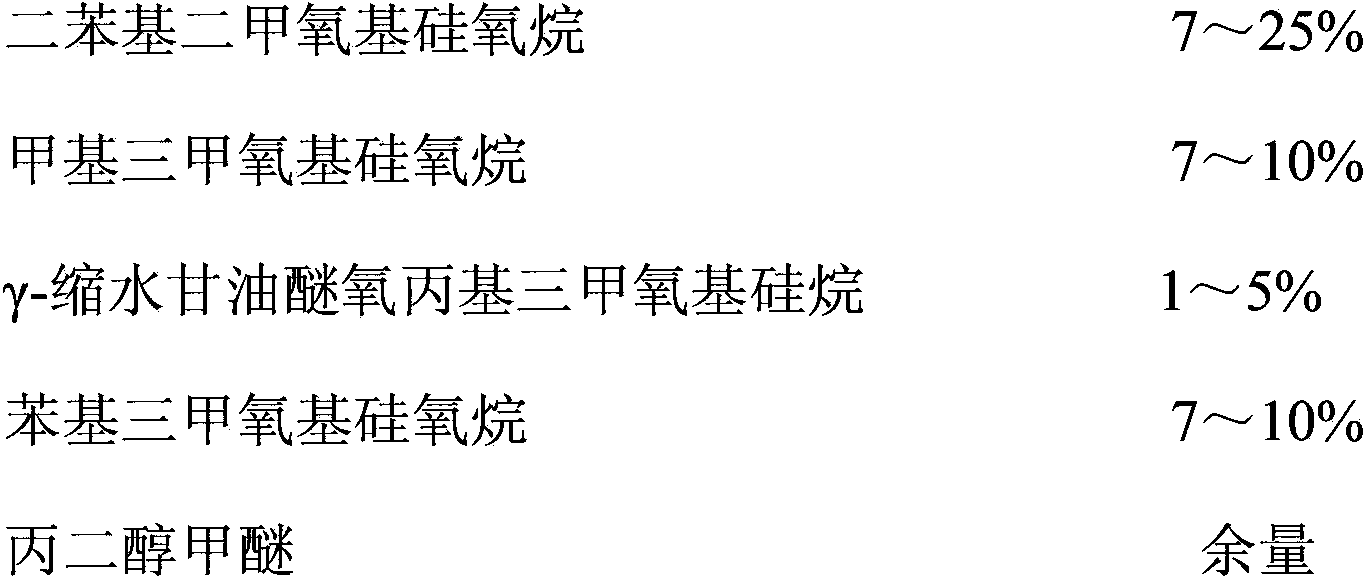

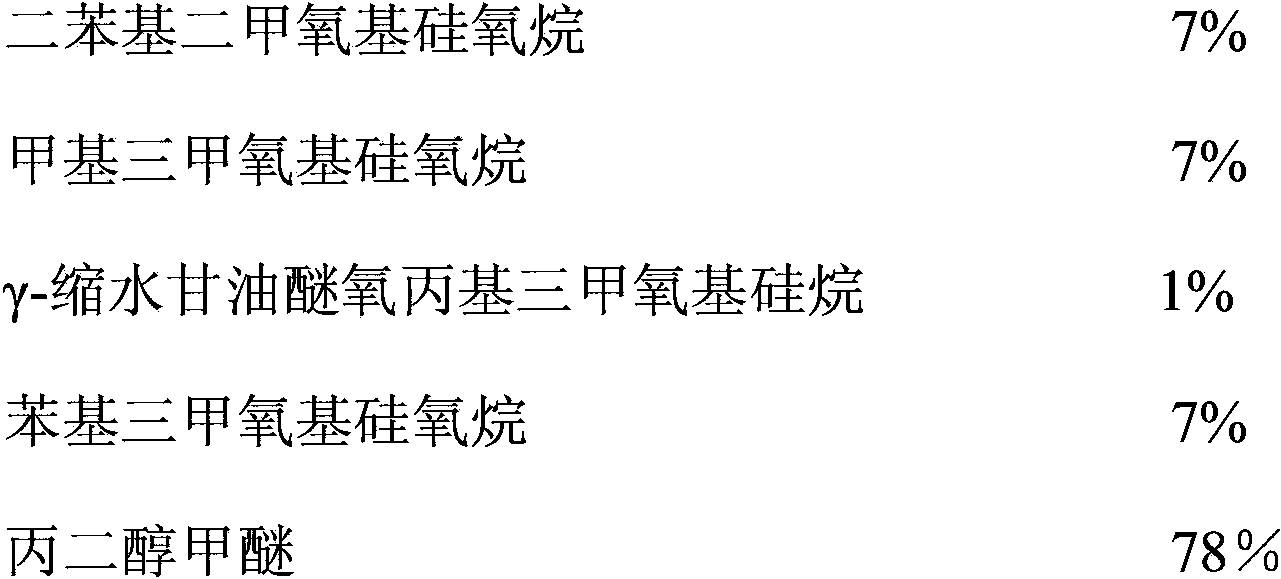

[0044] Described basic paint, its component volume percent is:

[0045] pH regulator 10%

[0046] Functional catalyst 0.002%

[0047] Silicone Composition 89.998%

[0048] The preparation method of described basic paint, its concrete steps are:

[0049] 1. Control the temperature in the reactor at 40°C, and add the siloxane composition according to the amount while stirring. The stirring rate is 300r / min, and the stirring is slow for about 5 minutes until the mixture is uniform;

[0050] Second, the H in the pH regulator 2 Mix O and the mixed acid evenly in another clean container, and slowly add it dropw...

Embodiment 2

[0073] An anti-corrosion and high-gloss paint, which comprises a base paint and a silicone resin, the volume ratio of the base paint and the silicone resin is 1:2.

[0074] The invention relates to a preparation method of an anti-corrosion and high-gloss coating. After mixing a basic coating and a silicone resin, the anti-corrosion and high-gloss coating is obtained.

[0075] Described basic paint, its component volume percent is:

[0076] pH regulator 18%

[0077] Functional catalyst 0.2%

[0078] Silicone composition 81.8%

[0079] The preparation method of described basic paint, its concrete steps are:

[0080] 1. Control the temperature in the reactor at 40°C, and add the siloxane composition according to the amount while stirring. The stirring speed is 300r / min, and the stirring speed is slow for about 5 minutes until the mixture is uniform;

[0081] Second, the H in the pH regulator 2 Mix O and the mixed acid evenly in another clean container, and slowly add it drop...

Embodiment 3

[0099] An anti-corrosion and high-gloss paint, which comprises a base paint and a silicone resin, the volume ratio of the base paint and the silicone resin being 1:4.

[0100] The invention relates to a preparation method of an anti-corrosion and high-gloss coating. After mixing a basic coating and a silicone resin, the anti-corrosion and high-gloss coating is obtained.

[0101] Described basic paint, its component volume percent is:

[0102] pH regulator 25%

[0103] Functional catalyst 0.5%

[0104] Silicone Composition 74.5%

[0105] The preparation method of described basic paint, its concrete steps are:

[0106] 1. Control the temperature in the reactor at 40°C, and add the siloxane composition according to the amount while stirring. The stirring rate is 300r / min, and the stirring is slow for about 5 minutes until the mixture is uniform;

[0107] Second, the H in the pH regulator 2 Mix O and the mixed acid evenly in another clean container, and slowly add it dropwise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com