High-efficiency and clean coal gasification process

A coal gasification and clean technology, applied in the field of coal chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

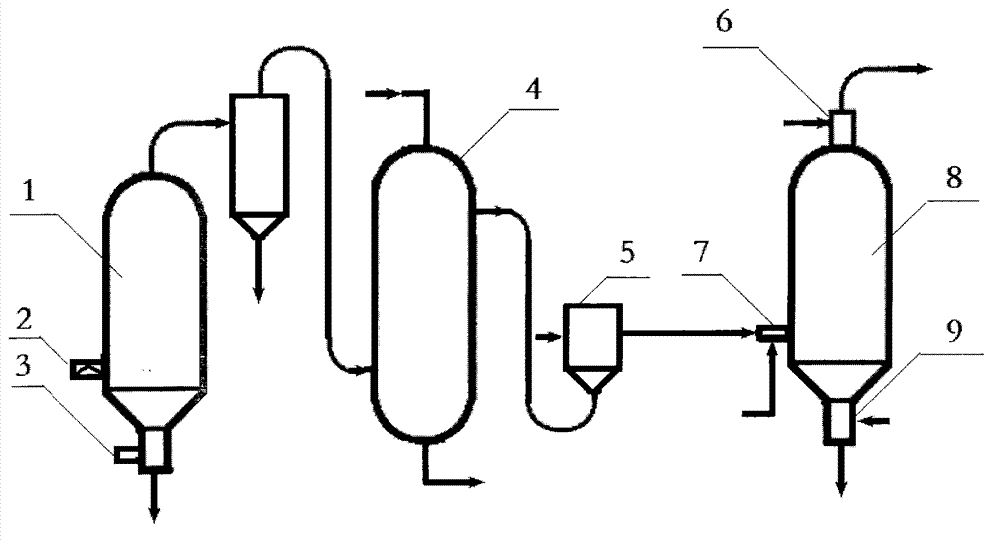

[0006] The pretreated raw coal enters the low-temperature gasification furnace or coking furnace 1 from the coal conveyor 2, and the gasification agent containing oxygen is sent to the low-temperature gasification furnace 1 through the gasification agent nozzle 3 for low-temperature gasification or combustion gas passes through the gas nozzle 3 Enter the coking furnace 1 for internal combustion and heating for coking. The crude gas or coke oven gas produced passes through the coal tar and chemical recovery device 4. After recovering coal tar and chemicals, it enters the gas and coal powder mixing conveying device 5. After the crude gas or coke A certain amount of pulverized coal or other carbon-containing substances are added to the furnace gas and enter the high-temperature entrained-bed gasification furnace 8, and the high-temperature gasification reaction is carried out together with the oxygen or the gasification agent containing oxygen added through the gasification agent n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com