In-situ uranium leaching and mining treatment method by adding O2 into CO2

A treatment method and in-situ leaching technology, which is applied in the direction of mining fluids, earthwork drilling, boreholes/well components, etc., can solve problems such as blockage of underground ore-bearing aquifers, groundwater pollution, etc., and improve salinity and desorption rate Enhanced, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Groundwater composition types of a uranium-bearing aquifer based on HCO 3 -Na and HCO 3 ·Cl-Na type is the main type, and the roof and floor of the uranium-bearing layer are mainly mudstone, with a relatively stable thickness and good water-proof performance. Salinity 3.5g / L, water temperature 15°C, pH 6.8, Eh: 150mv, HCO 3 - : 2000mg / L, O 2 <2mg / L, the hydrogeochemical environment is in a weak oxidation-reduction transition zone state.

[0023] Adopt the CO of a kind of uranium described in the present invention 2 Add O 2 The in-situ leaching mining treatment method comprises the steps of:

[0024](1) The leaching solution is natural bicarbonate-type groundwater (HCO in ore deposit groundwater 3 - content is 2000mg / L, pH value is 6.8), add O 2 After that, it is injected into the underground ore-bearing aquifer through the injection pipeline, and the injection pressure of the leaching solution is controlled at 1.6Mp, O 2 The adding pressure of the solution is ...

Embodiment 2

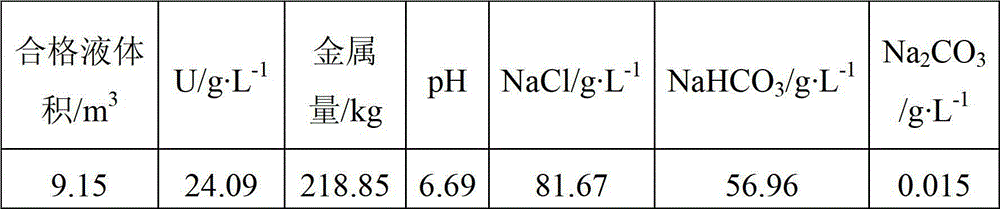

[0046] The water inflow in a uranium ore-bearing aquifer is 108m 3 / d, permeability coefficient 0.23m / d. The roof and floor of the uranium-bearing layer are mainly mudstone, with relatively stable thickness and good water-proof performance. Groundwater composition types in uranium-bearing aquifers in terms of HCO 3 -Na and HCO 3 Mainly Cl-Na type, salinity 5.7g / L, water temperature 16°C, pH 8.4, Eh: 400mv, HCO 3 - : 2600mg / L, the hydrogeochemical environment is in a weak oxidation-reduction transition zone state.

[0047] Adopt the CO of a kind of uranium described in the present invention 2 Add O 2 The in-situ leaching mining treatment method comprises the steps of:

[0048] (1) The leaching solution is natural bicarbonate-type groundwater (HCO in ore deposit groundwater 3 - content is 2600mg / L, pH value is 6.8), add O 2 After that, it is injected into the underground ore-bearing aquifer through the injection pipeline, and the injection pressure of the leaching solu...

Embodiment 3

[0074] The bicarbonate-type groundwater in-situ leaching uranium mining process described in the present invention is adopted in a uranium mining area. The water inflow of the ore-bearing aquifer in this mining area is 90m 3 / d, permeability coefficient 0.12m / d. The roof and floor of the uranium-bearing layer are mainly mudstone, with relatively stable thickness and good water-proof performance. Groundwater composition types in uranium-bearing aquifers in terms of HCO 3 -Na and HCO 3 Mainly Cl-Na type, pH value 7, Eh: 300mv, HCO 3 - : 2100mg / L, the hydrogeochemical environment is in a weak oxidation-reduction transition zone state.

[0075] Adopt the CO of a kind of uranium described in the present invention 2 Add O 2 In-situ leaching mining treatment method, which comprises the following steps:

[0076] (1) The leaching solution is natural bicarbonate-type groundwater (HCO in ore deposit groundwater 3 - content is 2100mg / L, pH value is 7), add O 2 After that, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com