Sparsely twisted type expanded lead

A technology of expanding diameter wire and aluminum wire, applied in the field of sparsely twisted diameter expanding wire, can solve the problems of poor structural stability of the wire, increase the overall weight of the wire, uneven distribution of the sparse winding layer, etc., and achieve simple structure and internal space stability. The effect of improving and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

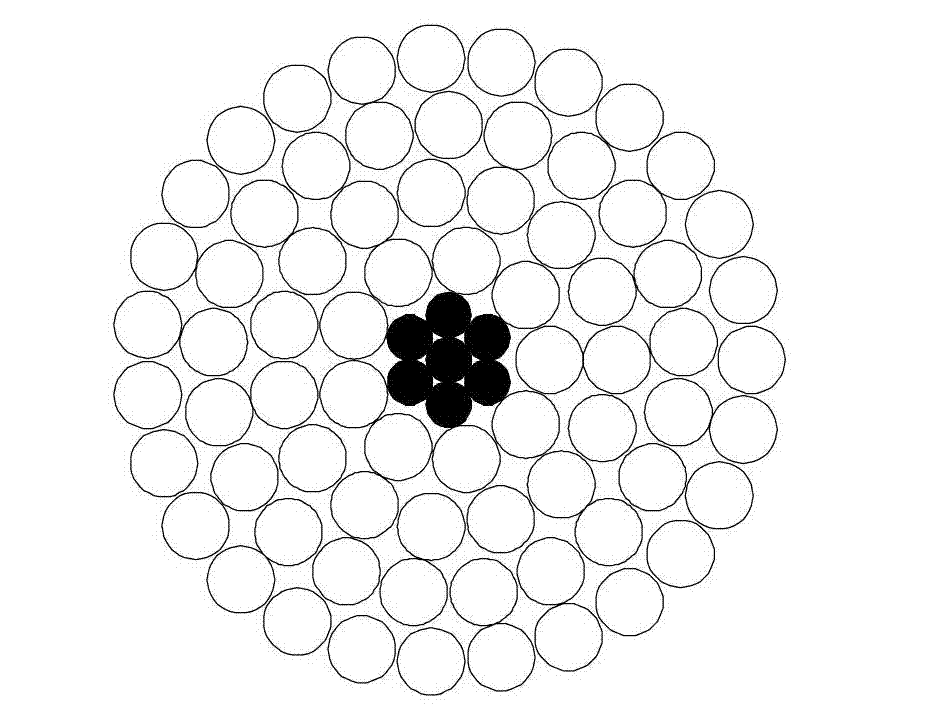

[0045] Embodiment 1, when the diameter-expanding wire adopts the structure of a round wire:

[0046] as attached image 3 As shown in the diameter-expanding wire of the round wire structure, the inner layer 2 is a single-layer structure, and the middle layer 3 is at least one layer structure; the inner layer 2 and the middle layer 3 have a diameter of D 1 and D 2 The wire is twisted, where D 2 1. D 1 D. 2 Type or D 1 D. 2 D. 2 Type, that is, the wire adopts a combination structure of large and small wires, or a combination structure of large and small wires. The staggered distribution structure of wires with different diameters enables the wires to achieve a larger diameter expansion rate and reduce corona loss. At the same time, the internal space stability of the wires is improved. After the critical tension test, there is no obvious indentation on the inner layer, which solves the problem of unstable wire expansion due to excessive gaps.

[0047] The outer layer 4...

Embodiment 2

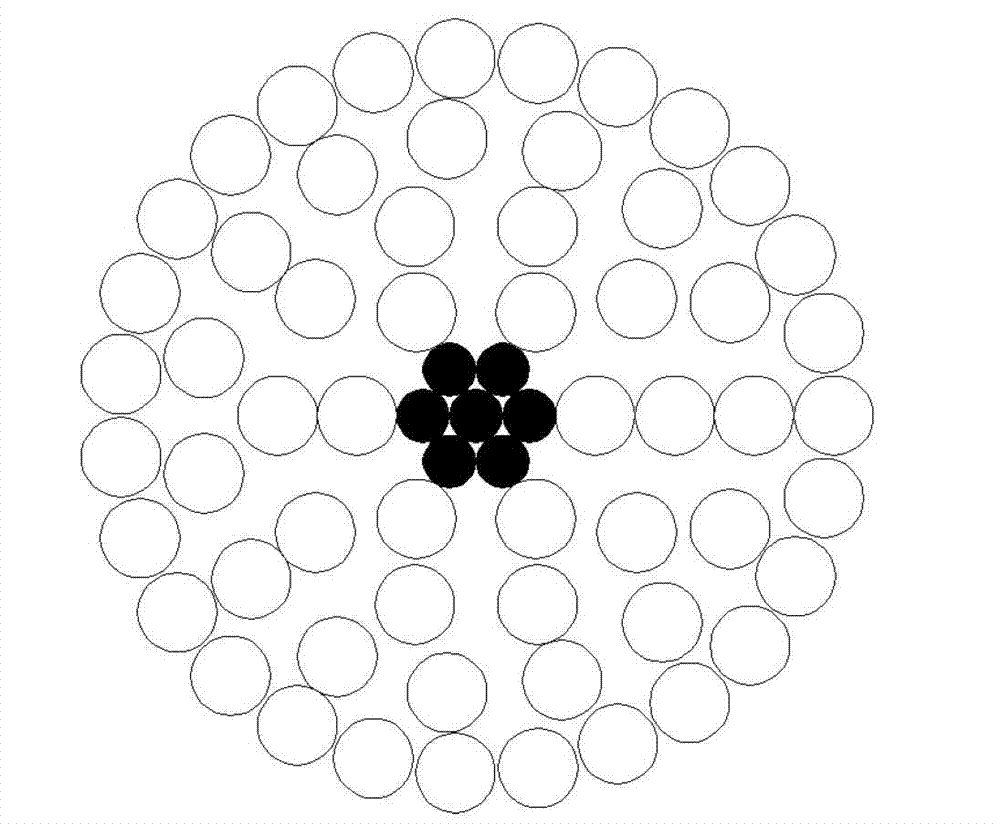

[0050] Embodiment 2, when the expanded-diameter wire adopts a "T"-shaped wire structure:

[0051] as attached Figure 4 As shown in the "T" type wire structure expansion wire, the inner layer 2 is a single-layer structure, and the middle layer 3 is at least one layer structure; the height of the inner layer 2 and the middle layer 3 is H 1 and H 2 The "T"-shaped wire is twisted, and the height of the "T"-shaped wire is the length of the aluminum wire along the radial direction of the expanded diameter wire, H 2 1 . h 1 The cross-sectional area of the wire is S 1 , H 2 The cross-sectional area of the wire is S 2 , where S 2 1 . H 1 h 2 Type or H 1 h 2 h 2 Type, that is, the wire adopts a combination structure of large and small wires, or a combination structure of large and small wires. Conductors with different heights adopt a staggered distribution structure, which enables the conductors to achieve a larger diameter expansion rate and reduce corona loss. At t...

Embodiment 3

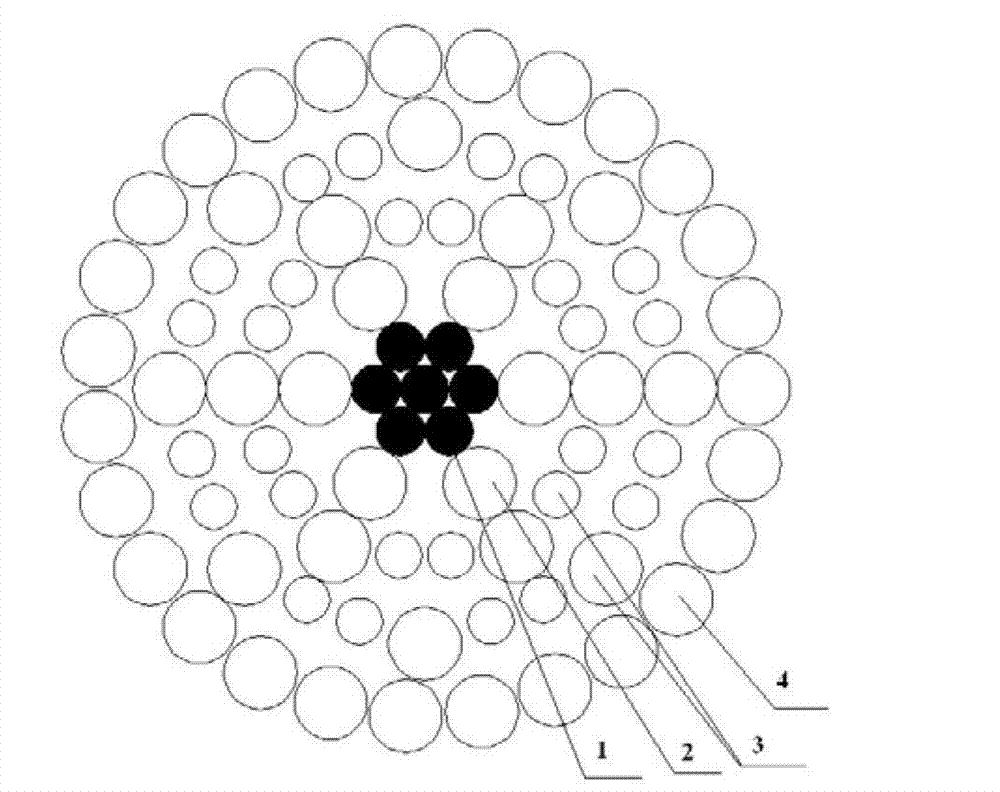

[0056] The diameter-expanding wire can also adopt the round wire structure of the inner layer 2 and the middle layer 3, and the "T" wire structure of the outer layer 4. The wire size on the same circumference of the outer layer 4 must be consistent. Figure 5 As shown, the layout of the wires in the inner layer 2 and the middle layer 3 is the same as that in Embodiment 1.

[0057] In order to increase the calculated breaking force of the wire, the aluminum alloy wire with higher strength is used for the single wire. The expanded diameter conductor of this structure adopts high-strength aluminum alloy wire, which effectively reduces the weight of the conductor, and at the same time achieves the tensile force through the performance of the aluminum alloy itself, without the need for reinforced steel, and the conductor has no hysteresis loss during operation, which improves the performance of the conductor. delivery efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com