Method for manufacturing gate structure

A gate structure and structure surface technology, which is applied in the field of semiconductor integrated circuit manufacturing technology, can solve problems such as impact, insufficient stability, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

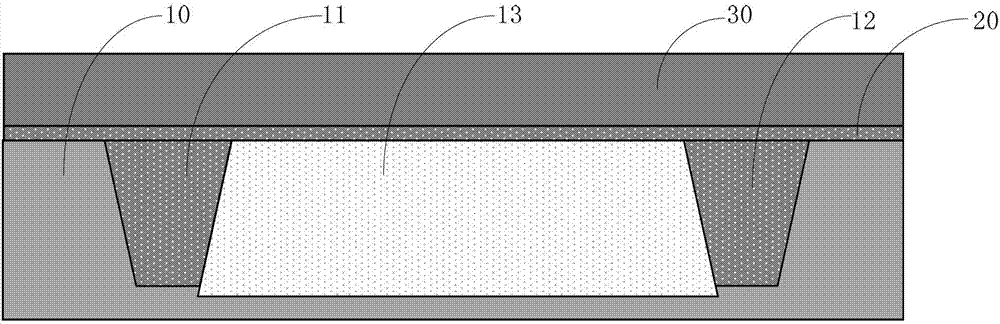

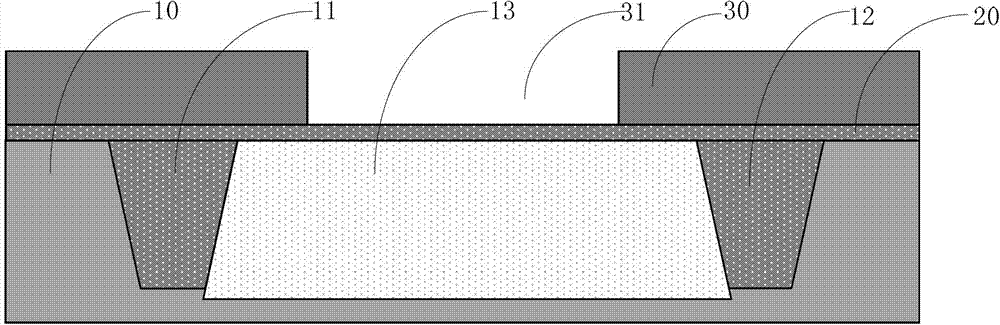

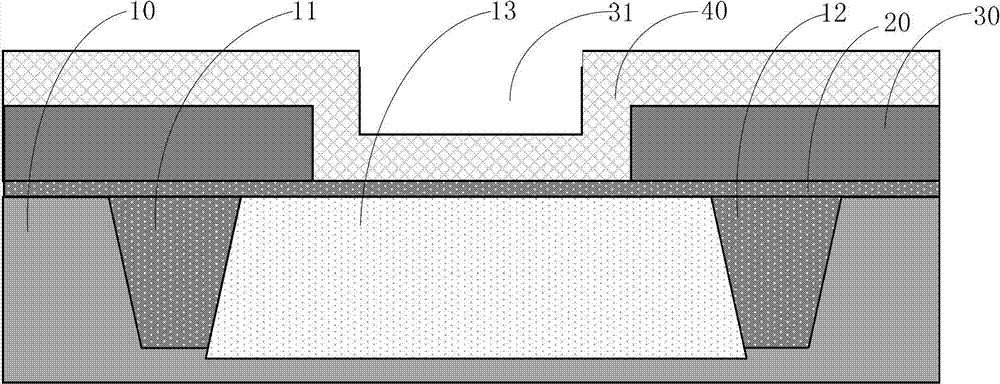

[0025] Figure 1-Figure 5 The process (cross-sectional view) of the method for fabricating a gate structure in Embodiment 1 of the present invention is shown.

[0026] see figure 1 ,

[0027] A substrate 10 is provided; a gate dielectric layer 20 is formed on the substrate 10 ; and a sacrificial layer 30 is deposited on the gate dielectric layer 20 .

[0028] The substrate 10 is a silicon substrate, and two device isolation layers 11 and 12 are formed in the substrate 10 . The two device isolation layers 11 , 12 are generally used to isolate the NMOS region and the PMOS region in the substrate 10 . The device isolation layer is formed by a shallow trench isolation (STI) method. A well 13 is formed between the two device isolation layers 11 , 12 .

[0029] The gate dielectric layer generally adopts oxide, nitride or oxynitride or composite. In this embodiment, silicon oxide is used for the gate dielectric layer 20 . Gate dielectric layer 20 is approximately 200 Angstroms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com