Copper loss rate decreasing type driven motor

A technology for driving motors and coils, applied in motors, electric vehicles, electric components, etc., can solve problems such as saturation magnetic flux density and magnetomotive force thinning, and achieve the effects of reducing influence, reducing copper loss, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is just one example, and those with ordinary knowledge in the technical field of the present invention can realize various forms, so it is not limited to the scope of this embodiment.

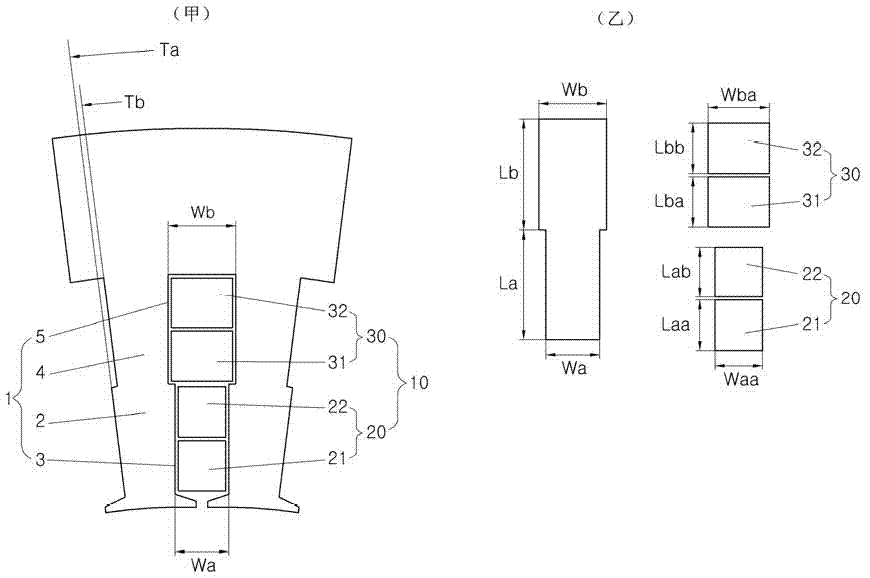

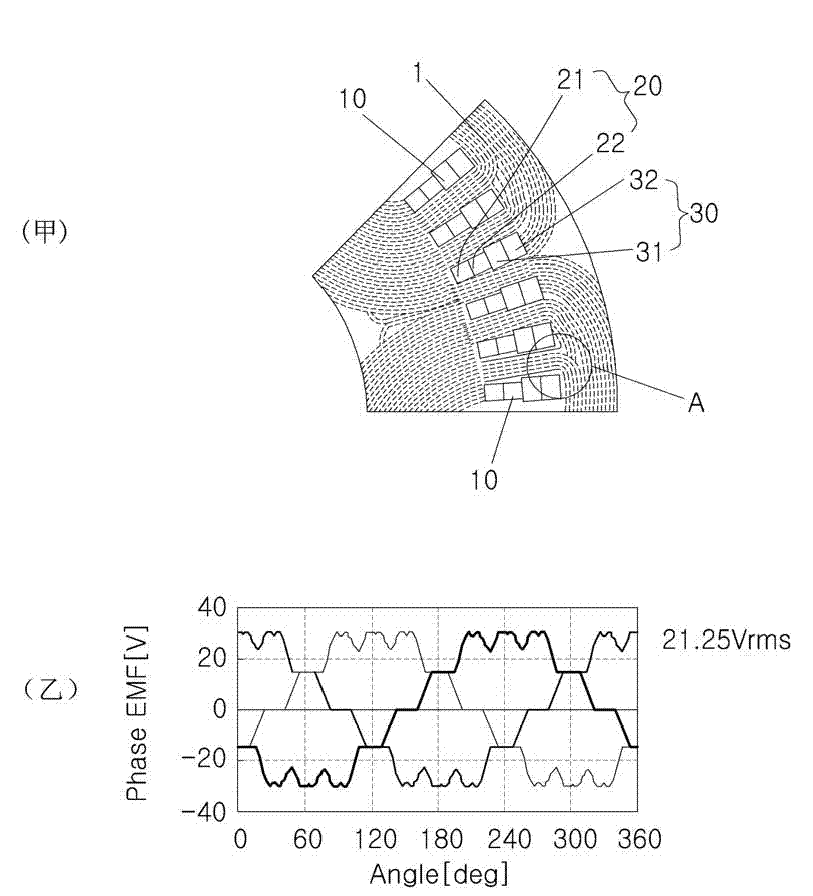

[0048] Fig. 1 shows the coil configuration of the copper loss reduction type drive motor of this embodiment.

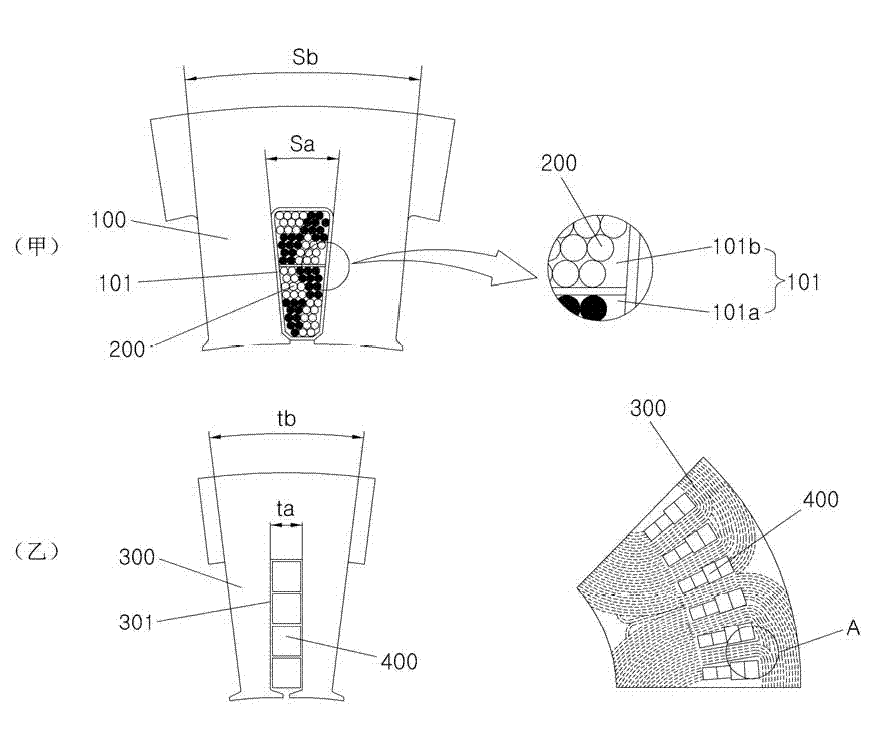

[0049] As shown in Figure 1A, the coil unit 10 is an empty space inside the core slot 1 that is wound to form a core (Core), that is, the coil spaces 3 and 5, but in order to prevent the formation of dead spaces (Dead Space) in the coil spaces 3 and 5 , so that the shape of the coil unit 10 is consistent with the coil spaces 3 and 5 .

[0050] The above-mentioned core slot wedge 1 has a structure in which the width gradually increases from the center to the periphery, and coil spaces 3 and 5 are formed inside the core slot wedge interval, but the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com