Method for manufacturing polytetrafluoroethylene high-frequency circuit board

A high-frequency circuit board, polytetrafluoroethylene technology, applied in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc. Stable, high precision, and the effect of improving product quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

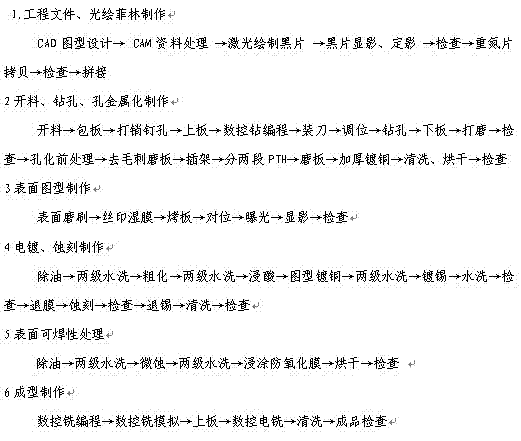

[0008] exist figure 1 Among them, the present invention is a manufacturing method of a polytetrafluoroethylene high-frequency circuit board, which includes the following steps: Step 1: Carry out engineering and photo-painting data production: first, carry out graphic design on the template, and use the designed graphics according to the production process According to the parameters, the engineering documents are processed, and then the processed documents are made up according to the production conditions. A high-precision laser photoplotter with a resolution of 20240dpi is used to make black negatives, and a 100-fold magnifying glass is used to wash and develop the photopainted negatives. Fixing, cleaning, air-drying; then check the finished negative, and finally use the checked negative as the master to copy the diazo film with a 5KW exposure machine, and check and splice the copied diazo film; step 2 : Production of material cutting, drilling, and hole metallization: First...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com