Metal foil for negative electrode collector

A technology of negative electrode current collector and metal foil, which is applied in the field of metal foil for new negative electrode current collector, can solve the problems of strength decrease, current collector strength decrease, etc., and achieve the effect of low resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

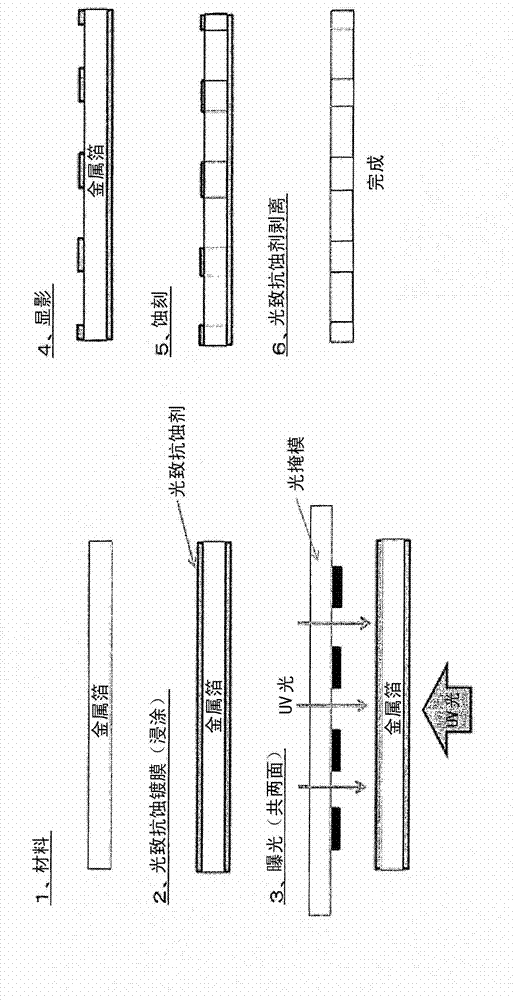

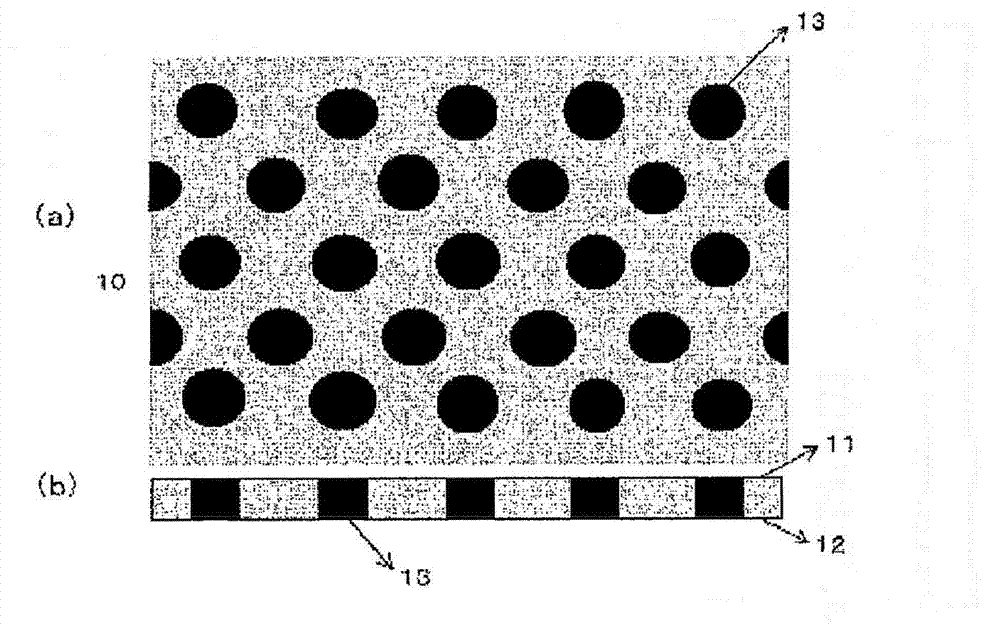

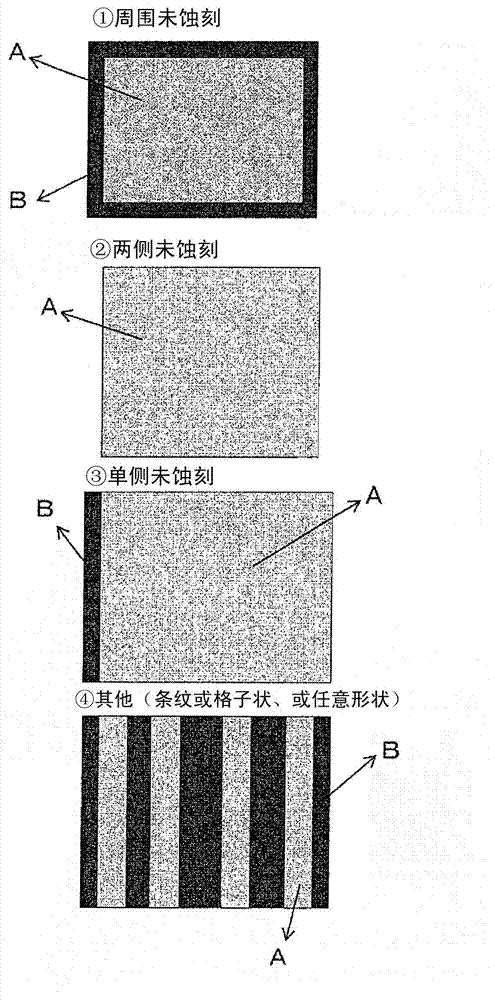

[0078] Electrodeposited copper foil, which is a coil-shaped winding product with a thickness of 10 μm, a width of 300 mm, and a length of 250 m, is dip-coated via a negative-type acrylic resin photoresist solution, and coated on both sides. After 5 μm, drying was performed at 80°C. by optical mapper as depicted by the Figure 4 Photomask of the pattern shown, irradiated at 100mj / cm on one side 2 Ultraviolet rays, on the other side, irradiate the above-mentioned ultraviolet rays on the entire surface under a matte mask. As a developing step, in order to dissolve the photoresist in the photomask portion, the photoresist was removed by dipping in a carbonated soda solution. The obtained material was immersed in copper chloride at a liquid temperature of 50° C. to etch the metal foil. The immersion time at this time was 30 seconds. After performing etching, the photoresist layer was stripped by dipping in a sodium carbonate (NaOH) solution. Then, antirust treatment, washing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com