Coloring agent for wear-resistant floor, and preparation method thereof

A dyeing agent and flooring technology, which is applied in the field of wear-resistant flooring dyeing agent and its preparation, can solve the problems of lack of literature on wear-resistant flooring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

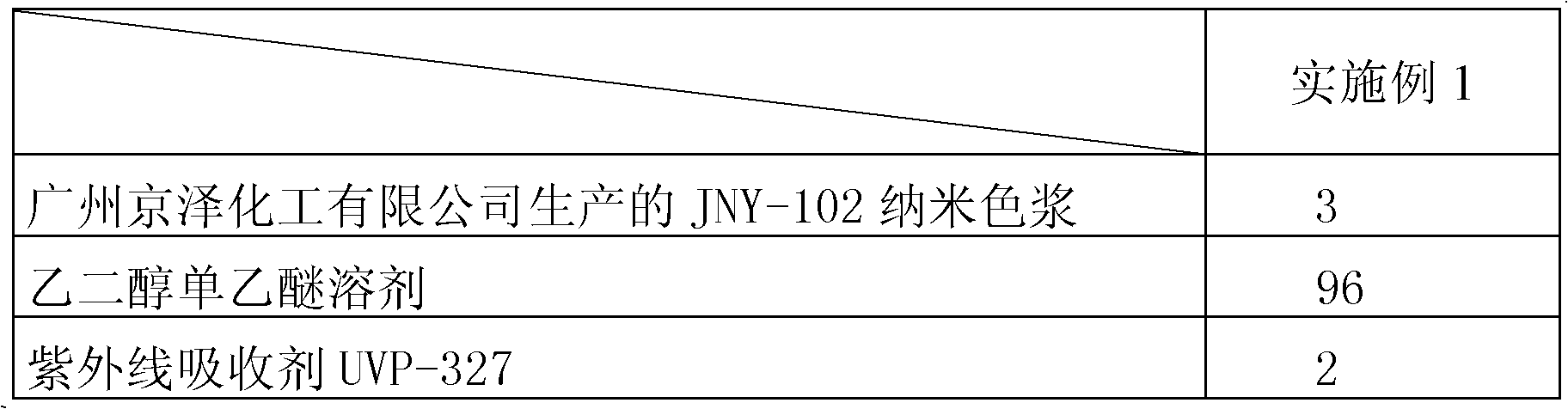

[0047] Table 1: Formula table of embodiment 1 Unit: kilogram

[0048]

[0049] Preparation method of staining agent for wear-resistant floor:

[0050] Weigh the nano-color paste, solvent and light stabilizer in proportion.

[0051] Pour the solvent into the blender, then add the light stabilizer and stir.

[0052] After 5 minutes, add nano color paste and continue stirring for 20 minutes.

[0053] After the inspection by the quality inspector, it will be packed.

[0054] Specific application of stains for wear-resistant floors:

[0055]After cleaning the surface of the wear-resistant floor, use a stone grinder for rough grinding with a 100-mesh resin grinding disc. After the rough grinding is completed, use a professional roller to evenly coat the wear-resistant floor stain on the base surface. The parts can be constructed with a paint brush. After it dries up, use a 400-mesh resin grinding disc to polish it for the second time, and repeat the dyeing work. After paint...

Embodiment 2

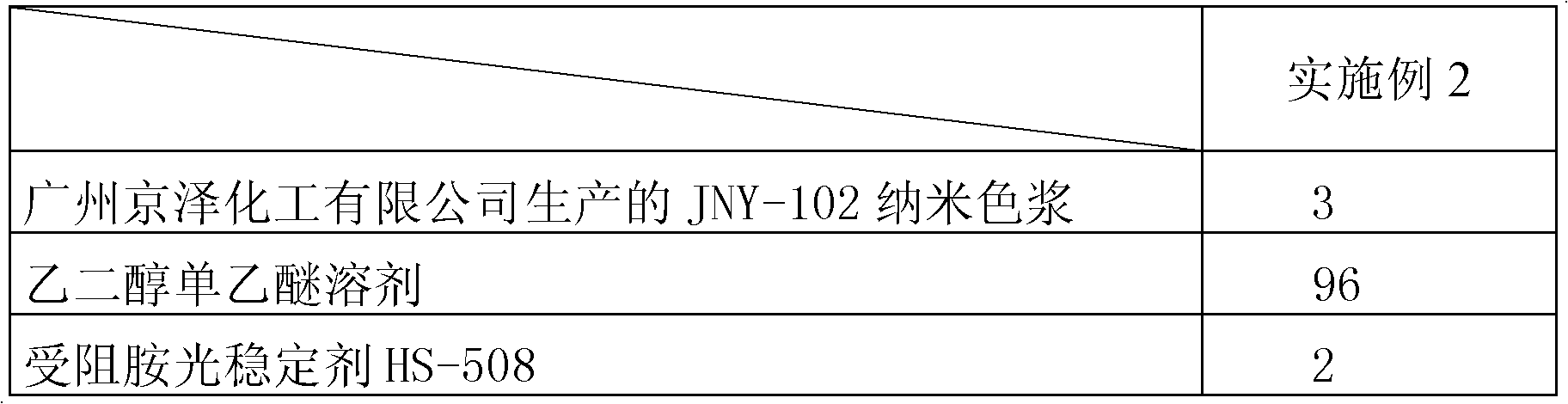

[0060] Table 2: Formula table of embodiment 2 Unit: kilogram

[0061]

[0062] The preparation method and specific application method of the dyeing agent for wear-resistant floor are the same as in Example 1.

[0063] Penetration depth: 1mm. Natural exposure test: 4 months to completely fade. The time used for the polishing and fading test: about 30 minutes.

Embodiment 3

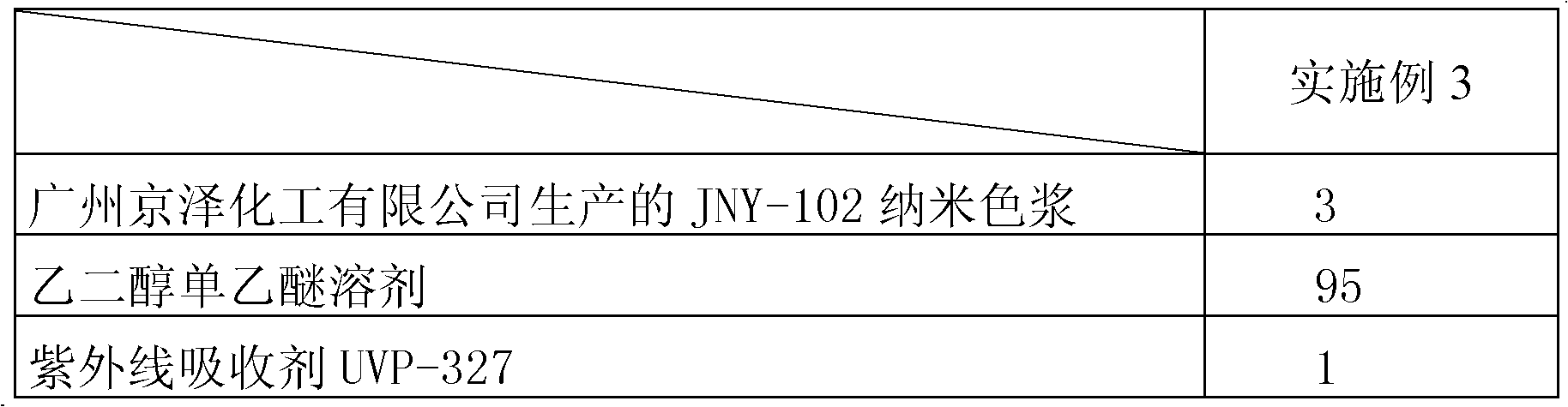

[0065] Table 3: Formula table of embodiment 3 Unit: kilogram

[0066]

[0067]

[0068] The preparation method and specific application method of the dyeing agent for wear-resistant floor are the same as in Example 1.

[0069] Penetration depth: 2mm. Natural exposure test: 6 months to completely fade. The time used for the polishing and fading test: about 50 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com