Method for extracting and purifying fucoxanthin from brown alga

A technology of fucoxanthin and purification method in brown algae, applied in the direction of organic chemistry, can solve the problems of long operation time, expensive, high processing cost, etc., achieve the effect of economical price, reduce residue, and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

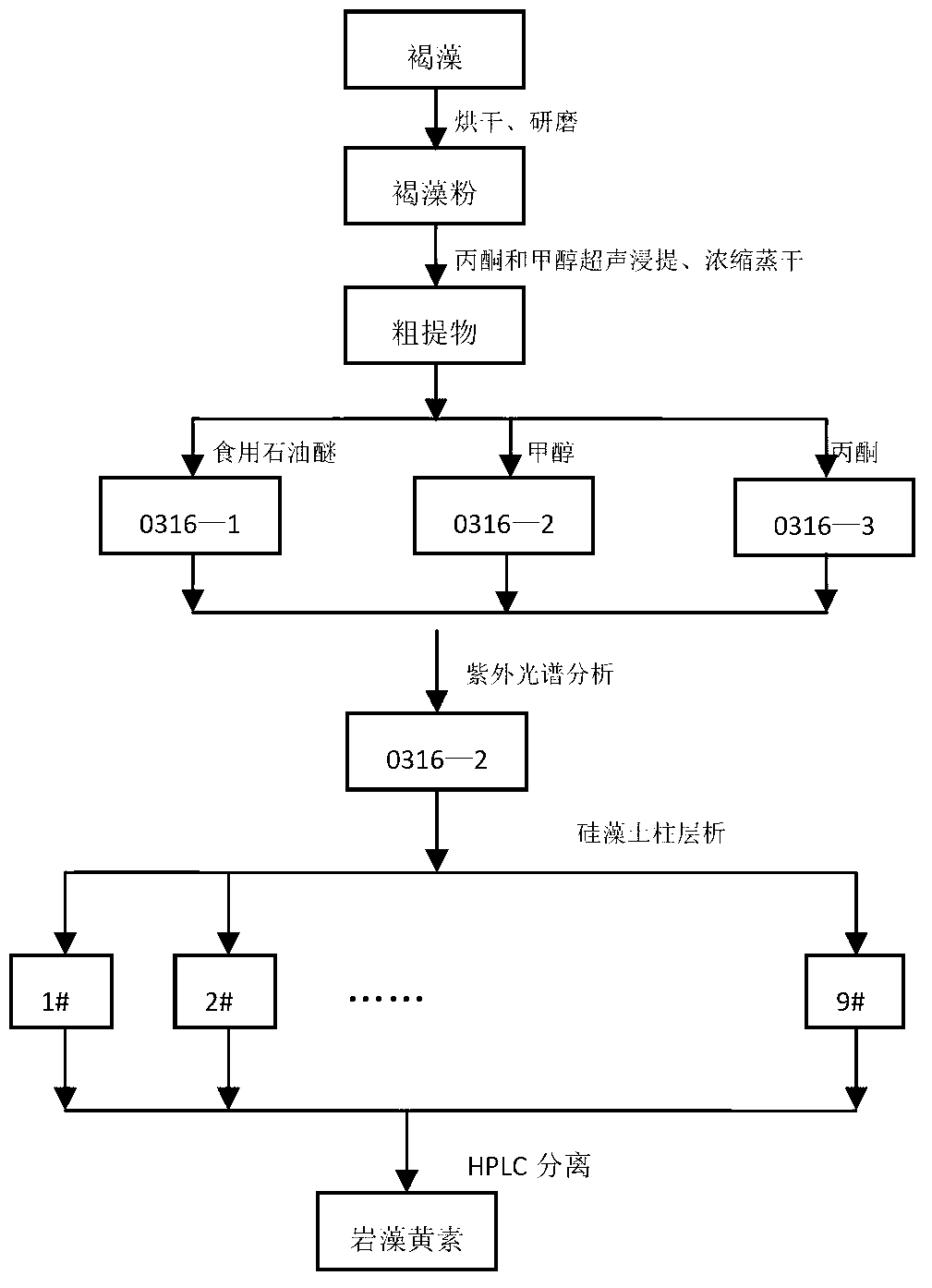

[0026] Embodiment 1: Extract and purify fucoxanthin from kelp

[0027] 1. Preparation and screening of kelp crude extract

[0028] Wash and dry 10kg of kelp, put it in an oven, and dry it at 45°C to obtain a dry weight of 346.49g of kelp. The dried kelp was crushed and ground into powder, and ultrasonically extracted with acetone:methanol=3:1 mixture at 45°C for 4 hours. Leach for 3 times, filter the extract, and evaporate the clear liquid to dryness under vacuum at 45°C to obtain the crude extract of kelp.

[0029] Edible petroleum ether, acetone and methanol were sequentially added to the crude kelp extract for dissolution to obtain samples 0316-1-3.

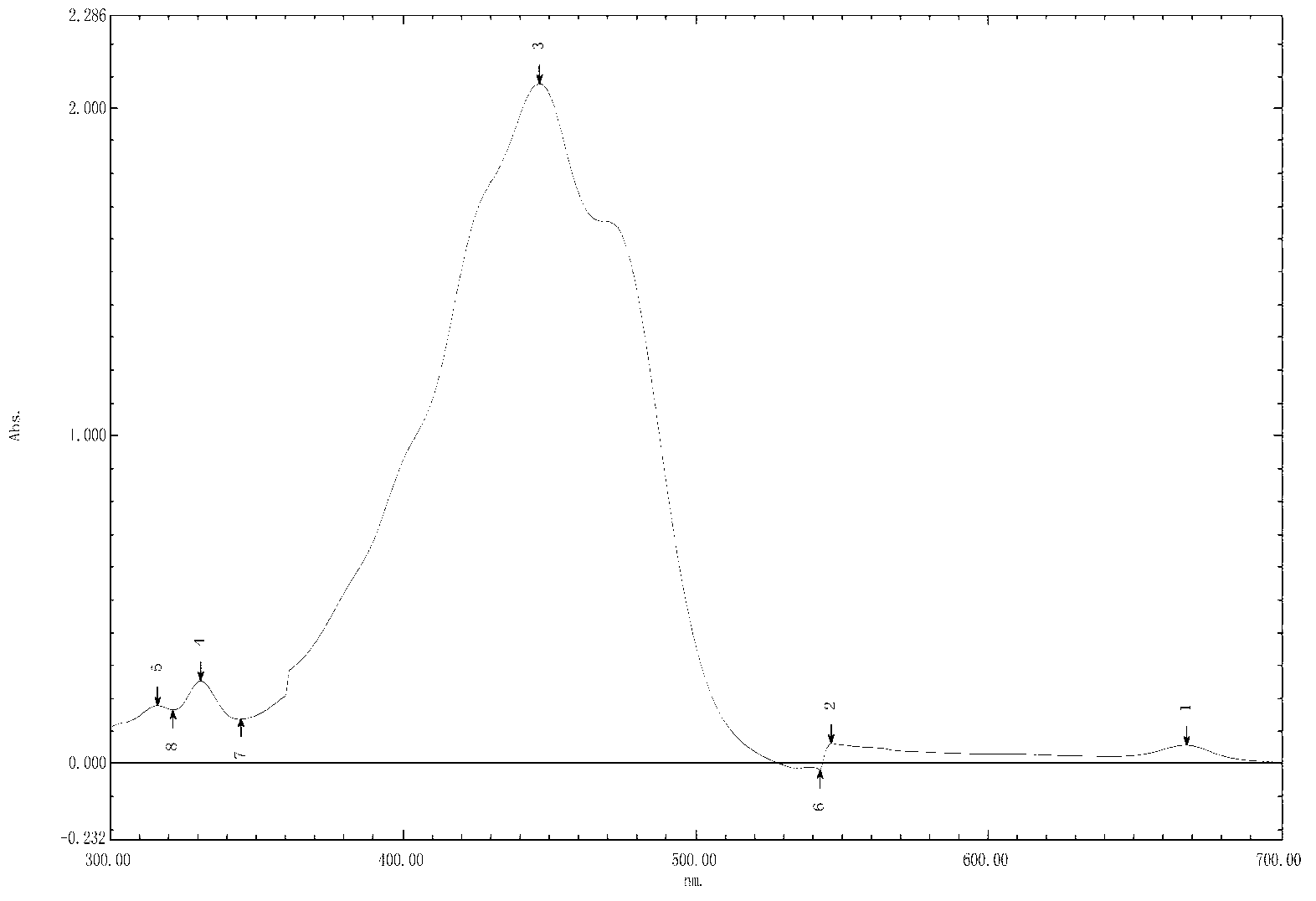

[0030] Use an ultraviolet spectrophotometer to scan the 0316-1~3 samples at a wavelength of 300~500nm, and use the corresponding pure solvent as a blank reference. The results show that the sample 0316-3, that is, the methanol extract has the largest absorption peak at 450nm, and the content of carotenoids and their derivat...

Embodiment 2

[0034] Example 2: Extraction and purification of fucoxanthin from macroalgae

[0035] 1. Preparation of macroalgae crude extract

[0036] Wash and dry 10kg macroalgae, put them in an oven, and dry them at 45°C. The dried macroalgae was crushed and ground into powder, and ultrasonically extracted with a mixture of acetone:methanol=3:1 at 45°C for 4 hours. Extracted 3 times, filtered the extract, and evaporated to dryness in a vacuum at 45°C to obtain a dry crude sample of macroalgae. Add 20ml of methanol to dissolve the dry sample and use it as a sample for column chromatography.

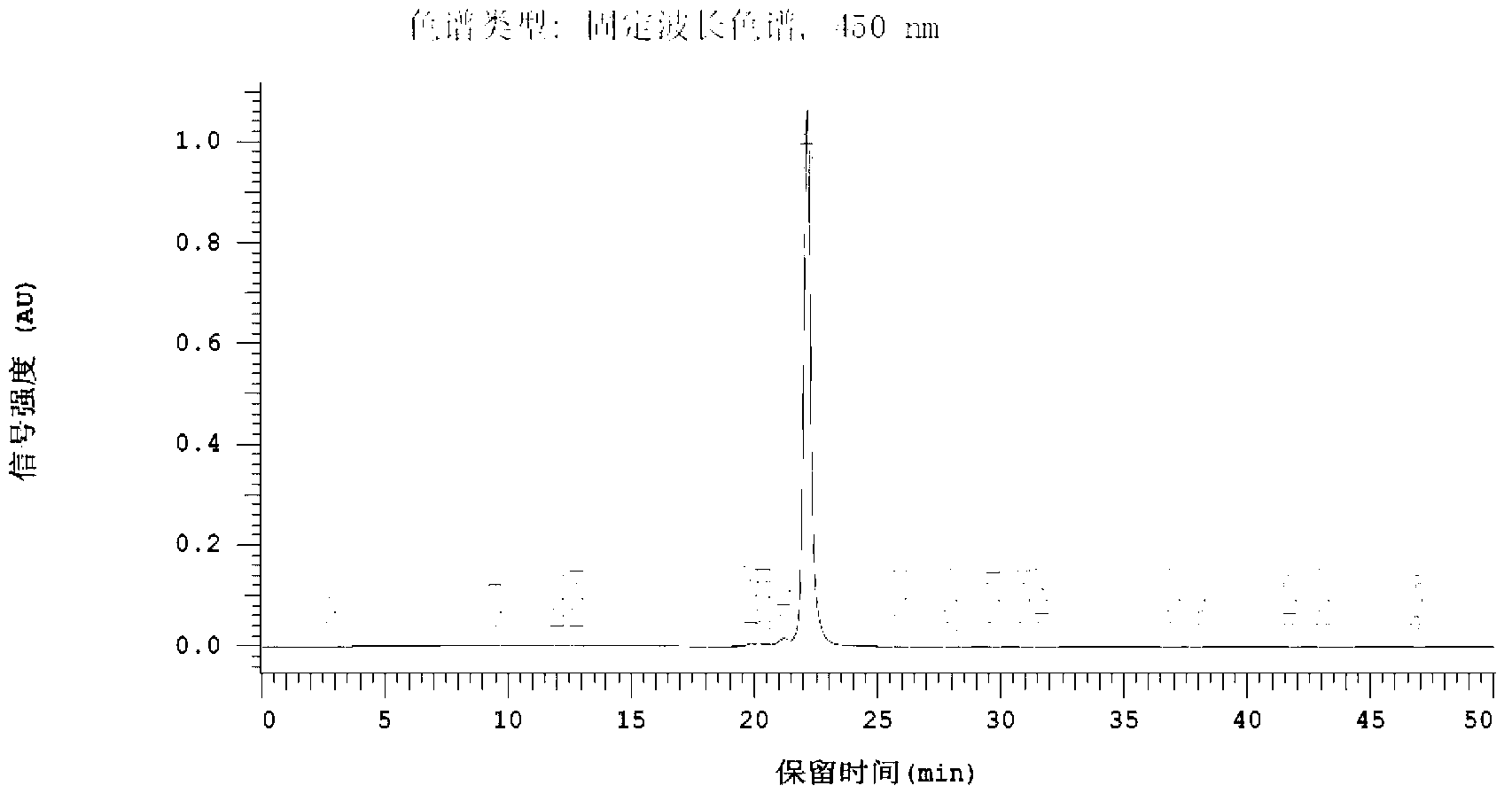

[0037] 2. Separation and purification of fucoxanthin

[0038] Firstly, the dry method is used to pack the column, and the column filler is diatomaceous earth. Add a small amount of diatomaceous earth to the samples obtained in the above steps, mix them dry and load them. Use edible petroleum ether and acetone with a volume ratio of 1:0.75 as the eluent for gradient elution, and finally use 1L of...

Embodiment 3

[0040] Embodiment 3: Extract and purify fucoxanthin from Sargassum

[0041] One, the preparation of Sargassum crude extract

[0042] Wash and dry 10kg of sargassum, place in an oven, and dry at 45°C. The dried Sargassum was crushed and ground into powder, and ultrasonically extracted with a mixture of acetone:methanol=3:1 at 45°C for 4 hours. Leach for 3 times, filter the extract, and evaporate the clear liquid to dryness in a vacuum at 45° C. to obtain a dry crude sample of Sargassum. Add 20ml of methanol to dissolve the dry sample and use it as a sample for column chromatography.

[0043] 2. Separation and purification of fucoxanthin

[0044]Firstly, the dry method is used to pack the column, and the column filler is diatomaceous earth. Add a small amount of diatomaceous earth to the samples obtained in the above steps, mix them dry and load them. Use edible petroleum ether and acetone with a volume ratio of 1:0.52 as the eluent for gradient elution, and finally use 1L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com