Impregnated pitch with low quinoline insoluble content, low softening point and high residual carbon and preparation process and application of impregnated pitch

A technology with low softening point and preparation process, which is applied in the field of impregnated asphalt, can solve the problems of low softening point of coking value, high equipment requirements, high investment, etc., and achieve the effect of shortening reaction time, reducing investment and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

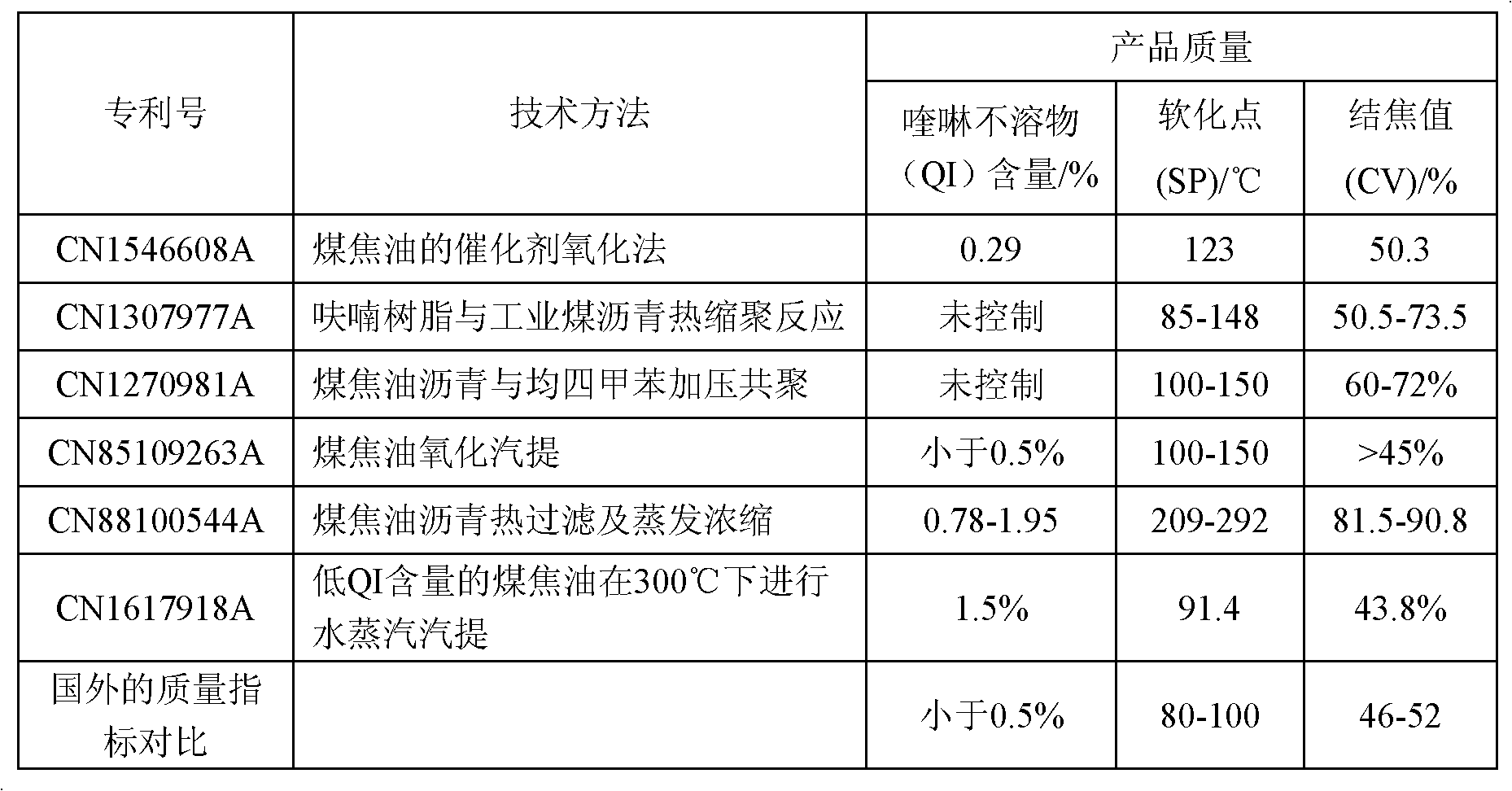

Problems solved by technology

Method used

Image

Examples

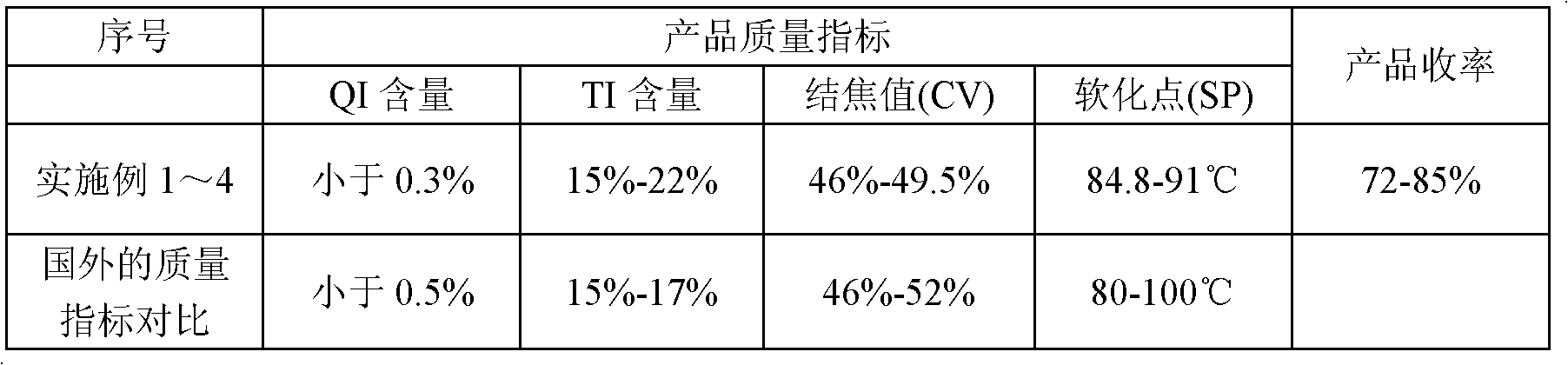

Embodiment 1

[0028] Add 800 g of raw material purified soft pitch (QI: <0.1%) into a three-necked flask, and under stirring at a rate of 541 rpm, the raw material is heated to 395 ° C at a heating rate of 7.5 ° C / min, and after 45 minutes of atmospheric thermal polycondensation, the raw material is heated to 8 ° C. The cooling rate of / min lowered the product to below 300°C to obtain 576 g of impregnated pitch, QI content: 0.10%, TI content 20.4%, coking value: 47.3%, softening point: 84.8°C.

Embodiment 2

[0030] Add 800 g of raw material purified soft pitch (QI: <0.1%) into the three-necked flask, and under stirring at a rate of 622 rpm, the raw material is heated to 375 ° C at a heating rate of 7.5 ° C / min, and after 75 minutes of normal pressure thermal polycondensation, the raw material is heated to 8 ° C. The cooling rate of / min lowered the product to below 300°C to obtain 680g of impregnated asphalt, QI content: 0.30%, TI content 17.4%, coking value: 46.6%, softening point: 88.6°C.

Embodiment 3

[0032] Add 800 g of raw material purified soft pitch (QI: <0.1%) into a three-necked flask, and under stirring at a rate of 786 rpm, the raw material is heated to 410 ° C at a heating rate of 8 ° C / min. The cooling rate of / min lowered the product to below 300°C to obtain 584g of impregnated pitch, QI content: 0.14%, TI content 19.4%, coking value: 48.76%, softening point: 91°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com