Processing technique for efficiently removing ocean oil spill

A treatment process and oil spill technology, which is applied in the cleaning of open water surfaces, water conservancy projects, and general water supply conservation, etc., and can solve problems such as refractory degradation, short action period, and low oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: a kind of treatment process of efficiently removing marine oil spill, comprises the following steps:

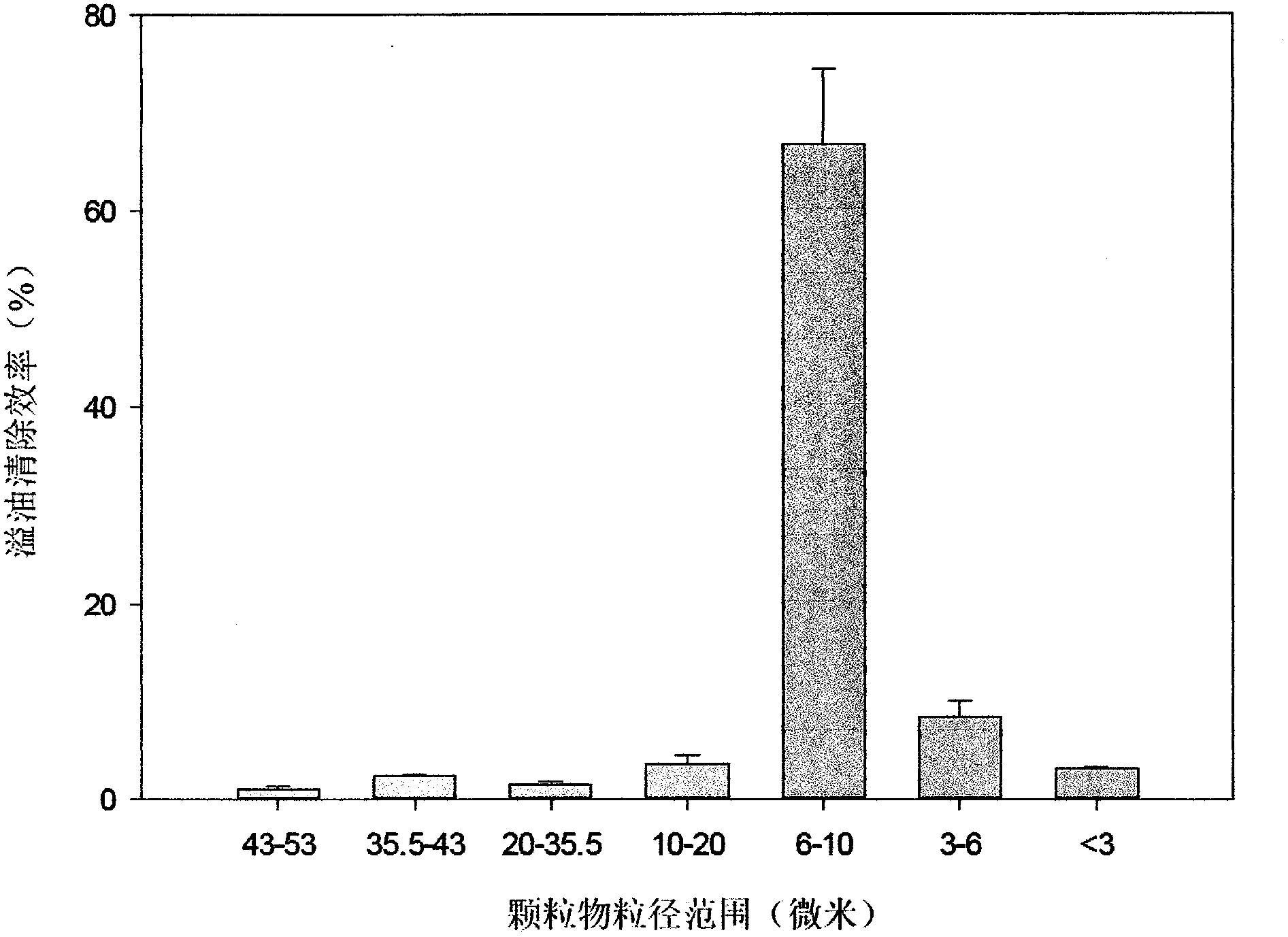

[0048] (1) Air-dry and sieve the sediments taken from the muddy beach at the estuary of the Dagu River, the content of organic matter in the described sediments is 8g / kg, and the density is 2.5g / cm 3 , to obtain particles with a particle size not greater than 35.5 μm;

[0049] (2) Sorting operation:

[0050] ① Filtrate the seawater taken from the sea area of Jiaozhou Bay with a 0.45 μm microporous membrane to obtain filtered seawater;

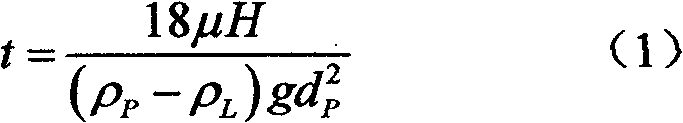

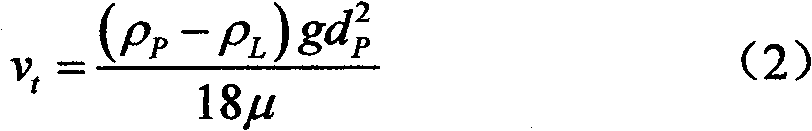

[0051] ②The appropriate height of the cylindrical reactor is marked as H, and the appropriate height of the bottom of the cylindrical reactor is marked as h; the particles with a particle size not greater than 35.5 μm obtained after air-drying and sieving are mixed with an appropriate amount of filtered seawater in the cylindrical reactor. Mix well in the reactor, make 10g / L seawater solution, and start timing;

[005...

Embodiment 2

[0060] Embodiment 2: a kind of processing technology of efficient removal marine oil spill, comprises the following steps:

[0061] (1) Air-dry and sieve the sediments taken from the silty beach at the estuary of the Dagu River, the content of organic matter in the described sediments is 10g / kg, and the density is 3.0g / cm 3 , to obtain particles with a particle size not greater than 35.5 μm;

[0062] (2) Sorting operation:

[0063] ① Filtrate the seawater taken from the sea area of Jiaozhou Bay with a 0.45 μm microporous membrane to obtain filtered seawater;

[0064] ②The appropriate height of the cylindrical reactor is marked as H, and the appropriate height of the bottom of the cylindrical reactor is marked as h; the particles with a particle size not greater than 35.5 μm obtained after air-drying and sieving are mixed with an appropriate amount of filtered seawater in the cylindrical reactor. Mix well in the reactor, make 10g / L seawater solution, and start timing;

[0...

Embodiment 3

[0073] Embodiment 3: a kind of processing technology for efficiently removing marine oil spills, comprising the following steps:

[0074] (1) Air-dry and sieve the sediments taken from the silty beach at the estuary of the Dagu River, the content of organic matter in the described sediments is 9g / kg, and the density is 2.8g / cm 3 , to obtain particles with a particle size not greater than 35.5 μm;

[0075] (2) Sorting operation:

[0076] ① Filtrate the seawater taken from the sea area of Jiaozhou Bay with a 0.45 μm microporous membrane to obtain filtered seawater;

[0077] ②The appropriate height of the cylindrical reactor is marked as H, and the appropriate height of the bottom of the cylindrical reactor is marked as h; the particles with a particle size not greater than 35.5 μm obtained after air-drying and sieving are mixed with an appropriate amount of filtered seawater in the cylindrical reactor. Mix well in the reactor, make 10g / L seawater solution, and start timing; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com