Air-cooled heat pump circulating system and heating and refrigerating methods thereof

A technology of circulation system and air-cooled heat pump, which is applied in the field of air-cooled heat pump circulation system and refrigeration system heat exchanger, can solve the problems of small heat transfer temperature difference and reduced heat transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

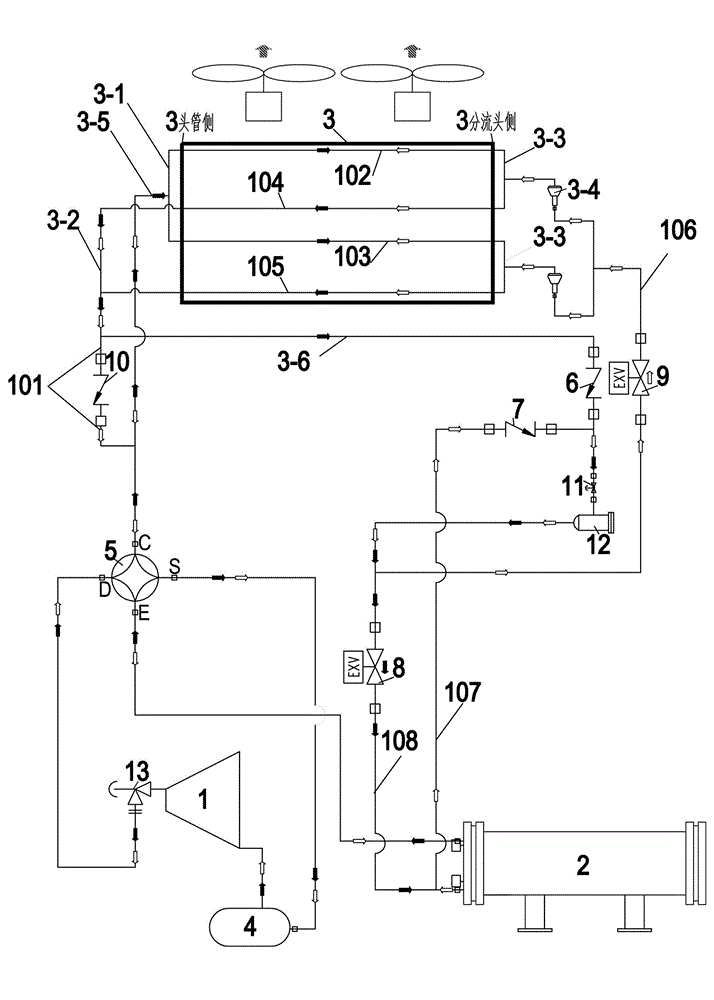

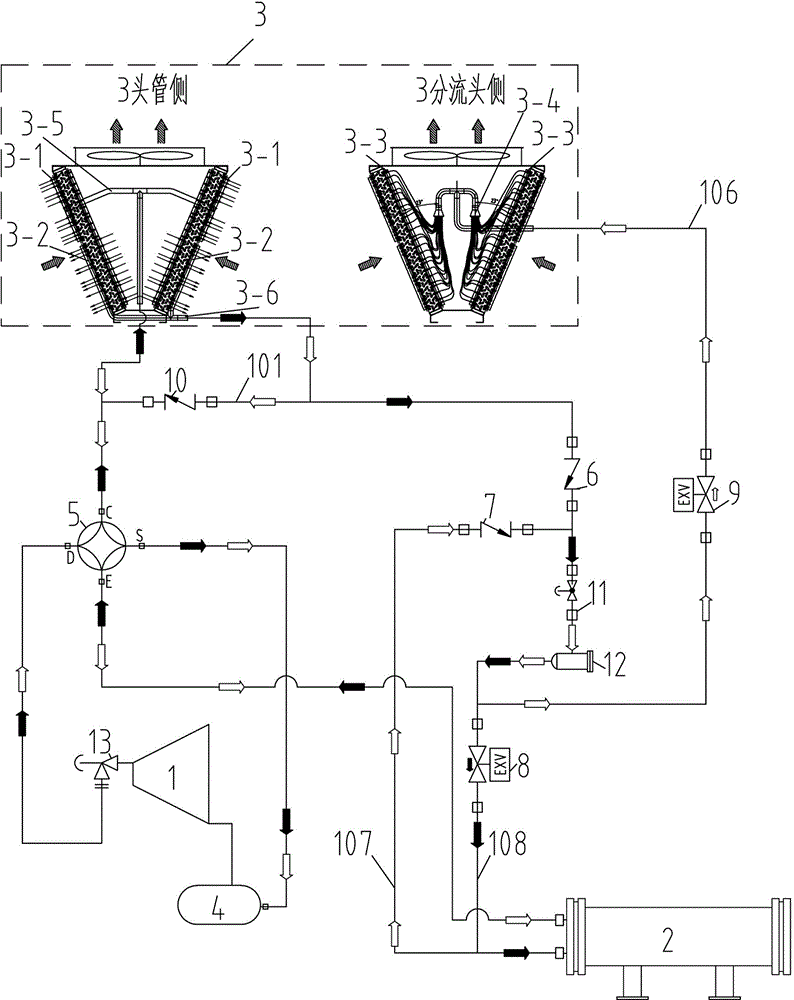

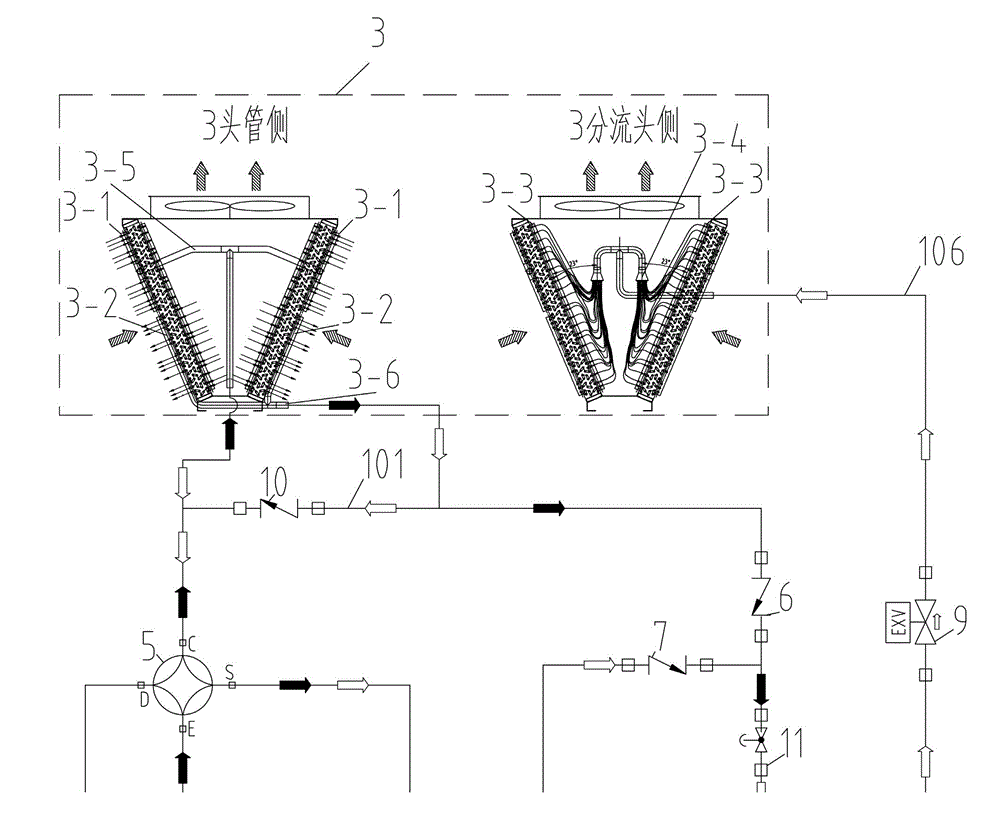

[0043] Refer to attached Figure 1~3 , an air-cooled heat pump circulation system includes a shell-and-tube heat exchanger 2, an air-cooled fin-tube heat exchanger 3, a compressor 1, a gas-liquid separator 4, a four-way reversing valve 5, a refrigeration check valve 6, Heating check valve 7, cooling expansion valve 8, heating expansion valve 9, heating suction check valve 10, exhaust angle valve 13, liquid stop valve 11 and liquid dry filter 12;

[0044] The air-cooled finned tube heat exchanger 3 has a condenser air header / evaporator return air header 3-1, a condenser liquid header / evaporator return air header 3-2, and a condenser secondary distribution set. Liquid pipe / evaporator liquid header 3-3, split head and split pipe 3-4, condenser exhaust head pipe / evaporator return head pipe 3-5 and condenser liquid phase pipe 3-6.

[0045] The exhaust port of the compressor 1 is connected to the air-cooled finned tube heat exchanger 3 through the exhaust angle valve 13, the D port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com