Method for making air bridge and inductance

An air bridge and inductor technology, applied in the field of microelectronics, can solve the problems of poor controllability of chlorobenzene, low precision of the air bridge, and complicated process of the sacrificial glue block supporting the air, so as to protect the health and reduce parasitics. effect, the effect of facilitating metal climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below through specific embodiments and accompanying drawings.

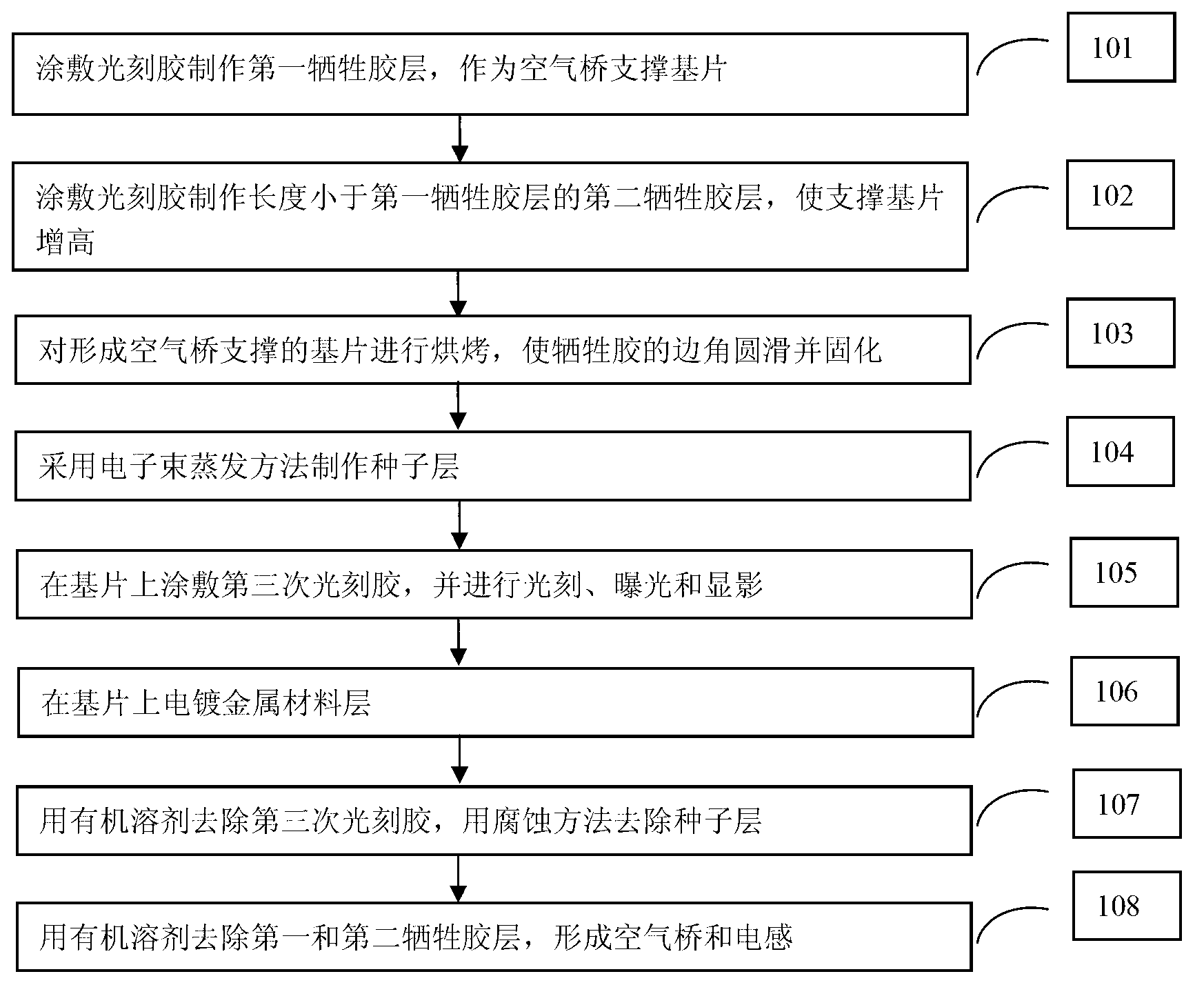

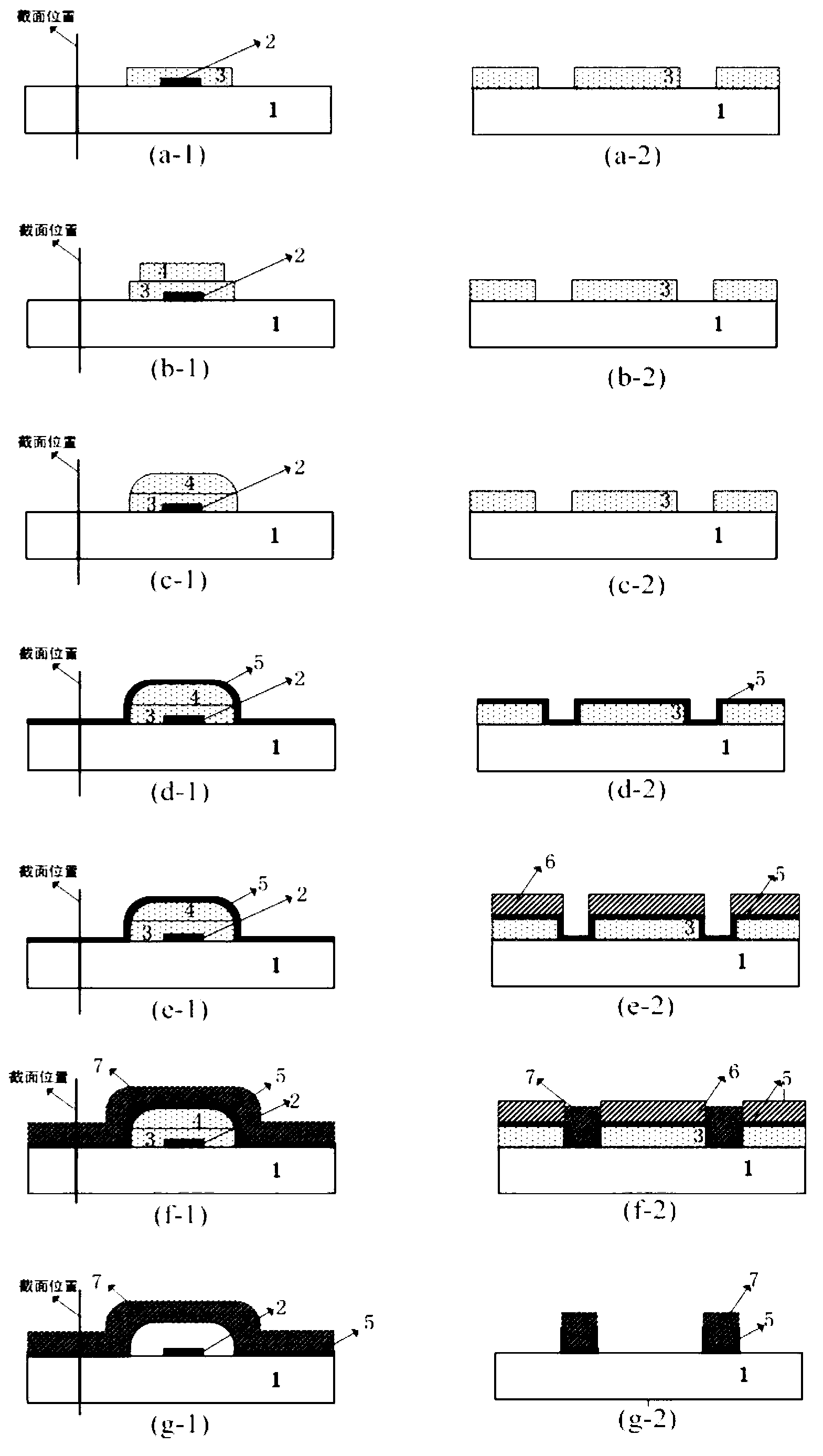

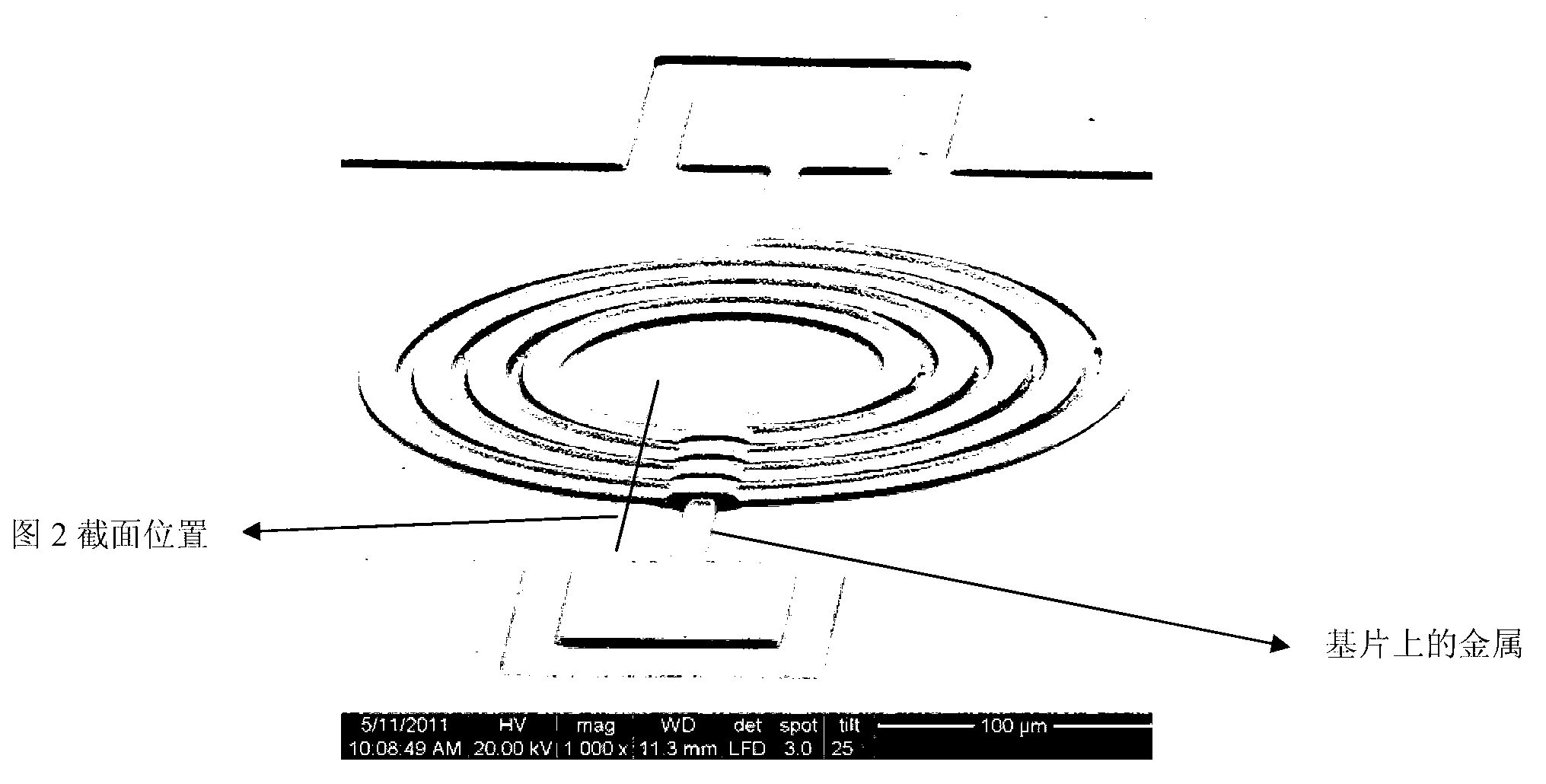

[0045] This embodiment is a manufacturing process of a spiral inductor. In order to avoid the overlapping of the lead wire of the inductor and the coil of the spiral inductor, an air bridge needs to be made. figure 1 For the flow chart of the steps of the method for making the air bridge of this embodiment, the specific instructions are as follows:

[0046] Step 101: Coating photoresist on the substrate to form a first sacrificial adhesive layer, and performing photolithography, exposure, and development on the sacrificial adhesive layer according to the defined pattern of the inductor coil. The undeveloped sacrificial adhesive layer at the metal lead-out line forms an air bridge to support the substrate.

[0047] When coating the sacrificial adhesive layer, it is necessary to cover the metal on the substrate, that is, the lead wire of the inductor. The met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com