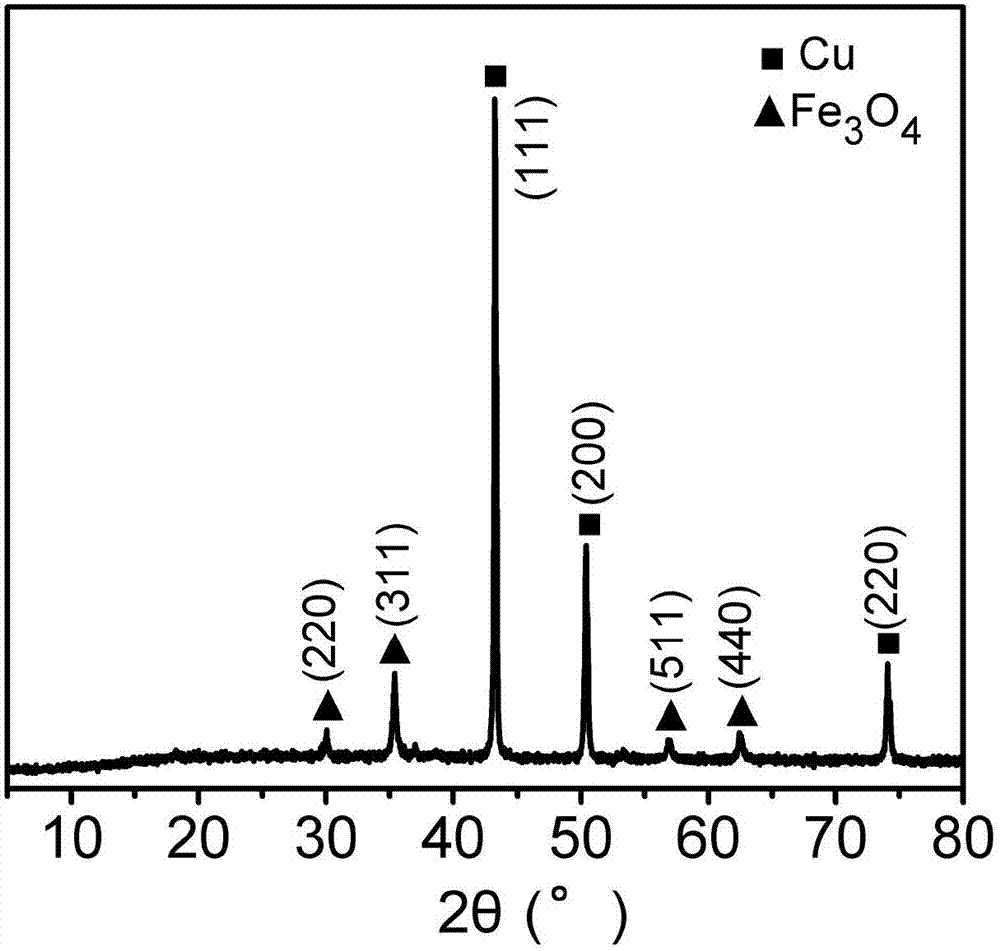

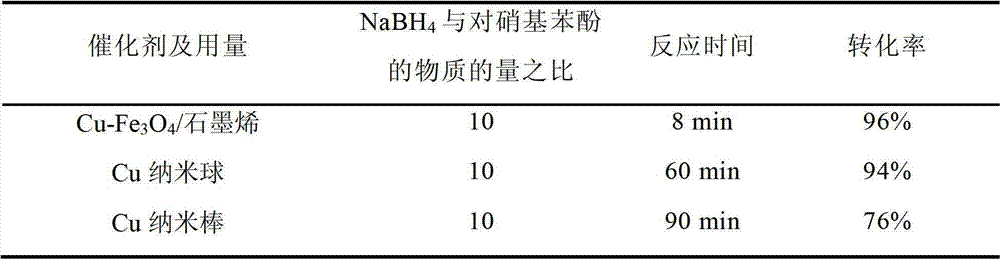

Preparation of magnetic nano Cu-Fe3O4/grapheme composite catalyst and application of composite catalyst in reduction of nitro-compounds

A graphene composite, cu-fe3o4 technology, which is applied in the preparation of amino compounds, organic compounds, amino hydroxyl compounds, etc., can solve the problems of complex process, restriction of industrial production, and many steps, and achieve simple method and recycling Convenience and the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

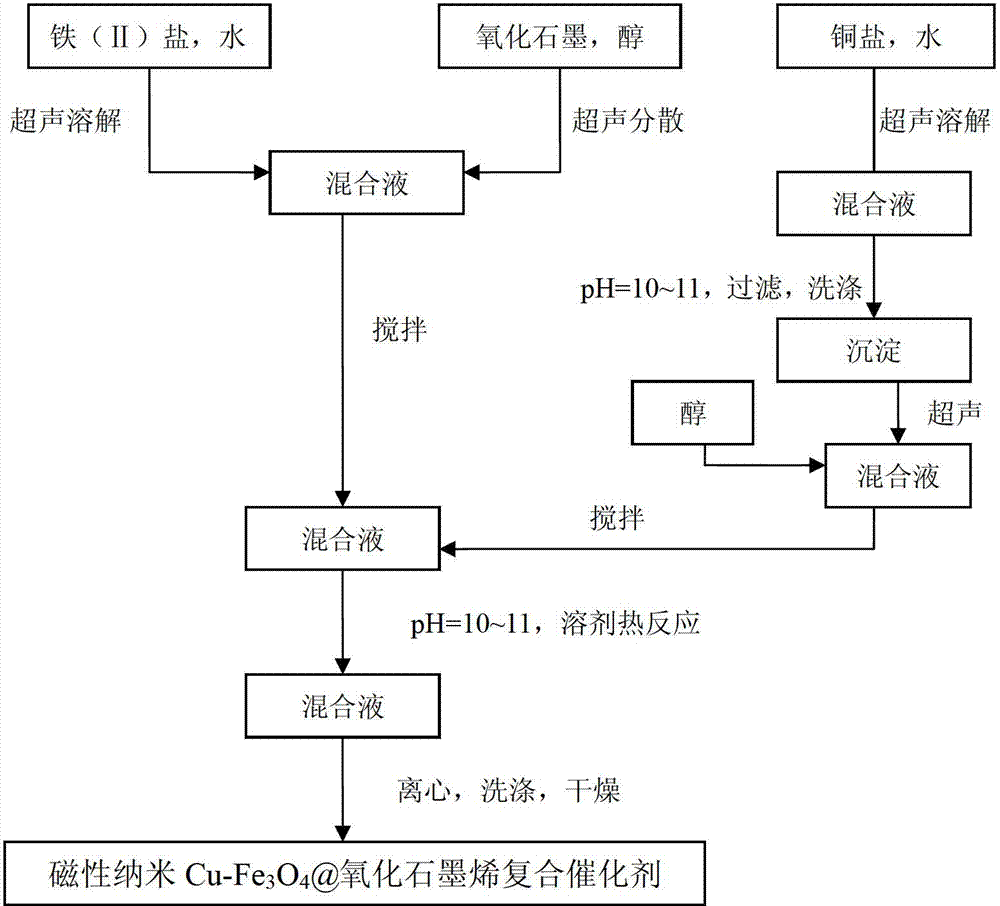

[0029] Embodiment 1: The present invention one-step solvothermal method prepares magnetic nanometer Cu-Fe 3 o 4 / graphene composite catalyst, comprises the following steps:

[0030] (1) Put 30mg of graphite oxide in 60mL of ethanol and ultrasonically disperse for 45min;

[0031] (2) Weigh 0.3025g of ferrous sulfate and ultrasonically dissolve it in 5mL of water, sonicate for 15min, add dropwise to step (1), and stir for 30min;

[0032] (3) Ultrasonic dissolve 0.9060g of copper nitrate in water, add sodium hydroxide solution to adjust the pH to 10~11, filter and wash to obtain a solid product, put it in ethanol for ultrasonic dispersion for 60min, and then add dropwise to the mixture of (2) Stir evenly, then add dropwise sodium hydroxide solution to adjust the pH to 10~11, stir evenly, place in a hydrothermal kettle, 200°C, and react for 10h;

[0033] (4) The product of step (3) is subjected to magnetic separation, and the solid product is separated, washed with deionized wa...

Embodiment 2

[0036] Embodiment 2: The present invention one-step solvothermal method prepares magnetic nanometer Cu-Fe 3 o 4 / graphene composite catalyst, comprises the following steps:

[0037] (1) Put 30mg of graphite oxide in 60mL of ethanol and ultrasonically disperse for 45min;

[0038] (2) Weigh 0.3528g of ferrous sulfate and ultrasonically dissolve it in 5mL of water, sonicate for 15min, add dropwise to (1), and stir for 30min;

[0039] (3) Ultrasonic dissolve 0.7520g of copper nitrate in water, add sodium hydroxide solution to adjust the pH to 10~11, filter and wash to obtain a solid product, place it in ethanol for ultrasonic dispersion for 60min, and then add dropwise to the mixture of (2) Stir evenly in the middle, then add dropwise sodium hydroxide solution to adjust the pH to 10~11, stir evenly, place in a hydrothermal kettle, 120°C, react for 24h;

[0040] (4) The product of step (3) is subjected to magnetic separation, and the solid product is separated, washed with deion...

Embodiment 3

[0041] Embodiment 3: The present invention one-step solvothermal method prepares magnetic nanometer Cu-Fe 3 o 4 / graphene composite catalyst, comprises the following steps:

[0042] (1) Place 30mg of graphite oxide in 60mL of ethylene glycol for ultrasonic dispersion for 45min;

[0043] (2) Weigh 0.1895g of ferrous chloride and ultrasonically dissolve it in 5mL of water, sonicate for 15min, add dropwise to (1), and stir for 30min;

[0044] (3) Dissolve 0.3021g of copper nitrate in water ultrasonically, add sodium hydroxide solution to adjust the pH to 10~11, filter and wash to obtain a solid product, place it in ethylene glycol for ultrasonic dispersion for 60min, and then add it dropwise to (2) Stir in the mixture evenly, then add dropwise sodium hydroxide solution to adjust the pH to 10~11, stir evenly, place in a hydrothermal kettle, 120°C, and react for 15h;

[0045] (4) The product of step (3) is subjected to magnetic separation, and the solid product is separated, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com