Horizontal reinforced polysaccharide polymer modification agitating ball mill reactor

A technology of polymer modification and agitation ball milling, applied in grain processing and other directions, can solve the problems of reduced ball milling efficiency, larger distance between the rod tip and ball mill cylinder, inconvenient to increase or decrease the number of plough blades, etc. The effect of suppressing heat-sensitive reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

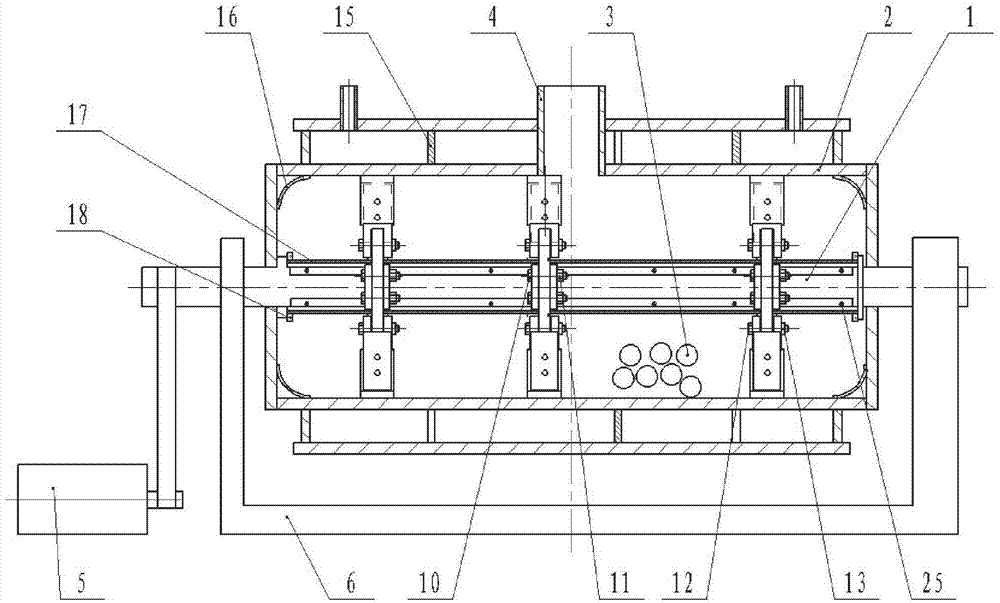

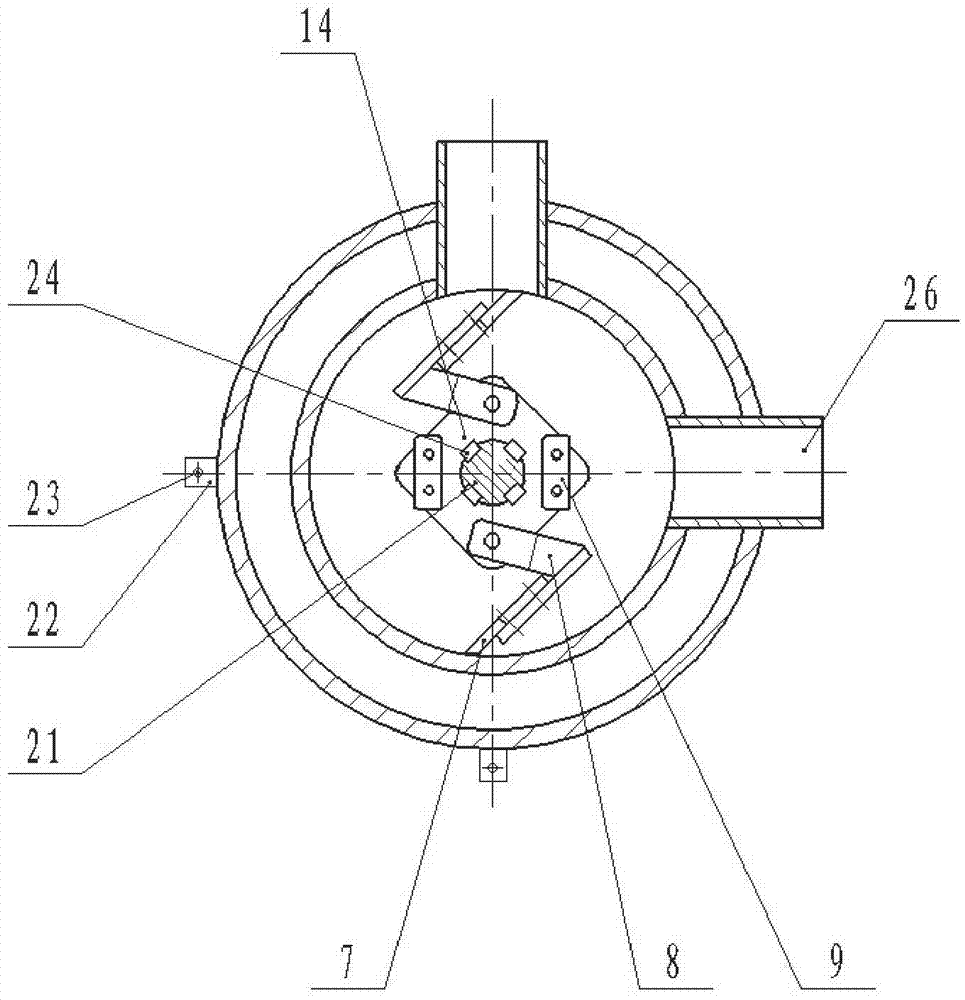

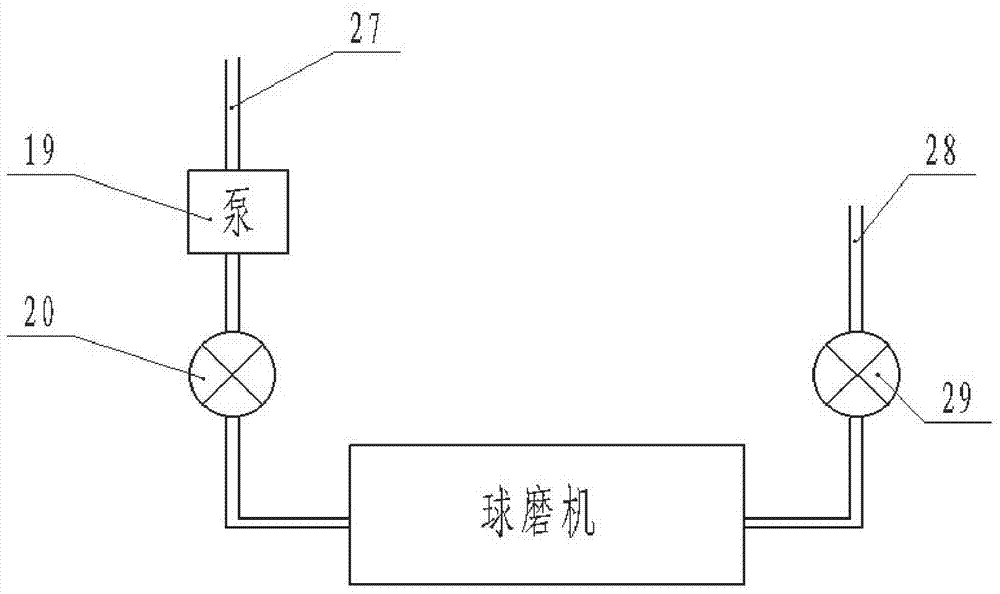

[0037] Such as figure 1 As shown, a horizontal reinforced polysaccharide polymer modified stirring ball mill reactor, the main structure includes a stirring device 1, a ball mill cylinder 2, a grinding ball 3 placed in the ball mill cylinder 2, a feed inlet 4, a motor 5 and an outlet The feed port 26, the stirring device 1 includes the main shaft 21 connected in sequence, the guide key 24 for transmitting torque, the spline seat 14, the U-shaped frame 8 and the plow blade 7, and the electric motor 5 is connected to the stirring device 1 through the transmission device. The main shaft 21 is connected to and drives the U-shaped frame 8 to swing radially along the main shaft 21. The plow blade 7 is driven by the U-shaped frame 8 to stir the grinding ball 3 to roll in the ball mill cylinder 2. Directly above the reactor, the discharge port 4 is located on the side of the ball mill reactor and arranged at 90 degrees to the feed port 26 .

[0038] In this embodiment, a mixing test ...

Embodiment 2

[0040] The difference from Embodiment 1 lies in that arc plates 16 are provided at both ends of the inner cylinder of the ball mill cylinder.

[0041]In this embodiment, the viscous material was subjected to a mixing test, and the reaction reagent was added during stirring. After 2 hours, no material stuck to the inner wall of the ball mill cylinder and the arc plate.

Embodiment 3

[0043] The difference from Embodiment 1 is that the spline seat 14 is provided with a pin shaft hole at both ends of the diagonal line, and is hinged with the U-shaped frame 8 through the pin shaft 12 and the elastic retaining ring 13, and the described main shaft 21 is provided with 4 keyways, and described guide key 24 sections are fixed in the keyway with screw 25, and described spline seat 14 can be disassembled symmetrically, is fixed together with connecting plate 9 and bolt 10, nut 11, and all The main shaft 21 is provided with a positioning sleeve 17 that can be disassembled symmetrically, and the positioning sleeve 17 is set on the main shaft 21 through a screw 18 .

[0044] In this embodiment, a group of agitating plow blades is added to the main shaft 21. First, the screws 18 on all the positioning sleeves 17 on the original main shaft 21 are removed, the position of the spline seat 14 is adjusted, and a plow blade is added at the required position. The key seat 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com