Method for gradient oxygen-increasing combustion supporting of glass melting furnace and special gradient oxygen-increasing combustion-supporting system

A glass melting furnace and combustion-supporting system technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of inability to reduce the NOx content of flue gas, high preheating temperature of oxygen-enriched gas, and not too high preheating temperature , to achieve the effect of protecting the parapet, reducing the temperature of the space flame, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

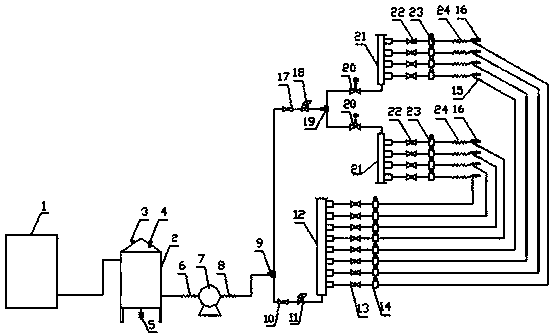

[0066] Taking the 600-ton float glass production line as an example, the oxygen production equipment produces 1000Nm of oxygen with a purity greater than 90%. 3 / h. Oxygen is sent to the oxygen collection tower from the outlet of the lower part of the air separator, and the oxygen sent from the outlet of the oxygen collection tower is sent to the 2-way oxygen split pipeline through the oxygen pressurizer and the three-way split connection, and the manual shut-off valve is used to The oxygen is distributed in proportion, and the distribution ratio is 3:7; one of them is decompressed to 0.09MPa through the low-pressure reducer, and the low-pressure oxygen decompressed by the low-pressure reducer is diverted to a low-pressure branch passage with 10 outlet ports. Each outlet port is connected to a low-pressure branch pipeline, and each low-pressure branch pipeline is connected in series with a low-pressure valve and a low-pressure flowmeter. The low-pressure flowmeter displays the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com