Technology for producing aluminium titanate material

A technology of aluminum titanate and raw materials, which is applied in the field of preparation of aluminum titanate (Al2TiO5) materials, can solve the problems of low expansion, complex additives, single additives, etc., to improve high temperature performance, inhibit thermal decomposition, reduce cracks and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

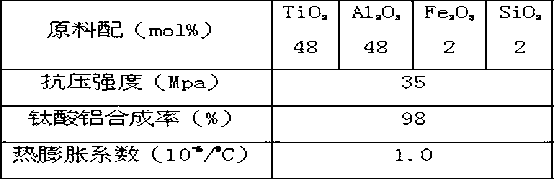

[0024] (1) Prepare chemically pure TiO 2 and industrial pure Al 2 o 3 and oxide additives (Fe 2 o 3 , SiO 2 ) powder, wherein: the molar ratio of each raw material component is: TiO 2 :Al 2 o 3 : Fe 2 o 3 : SiO 2 =49:49:1:1.

[0025] (2) Wet mixing is adopted, that is, the weighed mixed powder is added to 10% PVA and wet mixed to form a muddy mixture.

[0026] (3) When the mixture obtained in (2) is dried to a humidity of 5%, use the molding method to make the above muddy mixture into a cylindrical compact with a diameter of 20 mm and a height of 25 mm, and then place the compact in a drying oven at 100 ° C. Incubate for 5 hours in medium temperature, and the heating rate from room temperature to 100°C is 50°C / h.

[0027] (4) Put the dry compact in (3) into a high-temperature resistance furnace, and set the temperature rise program: the temperature rise rate is 50°C / h from room temperature to 400°C, and the temperature rise rate is 200°C / h from 400°C to 1450°C. h,...

Embodiment 2

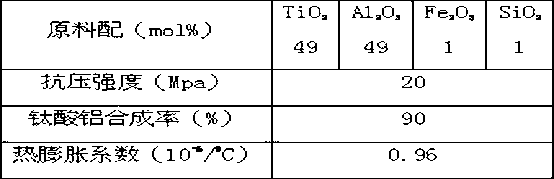

[0031] According to the ratio of raw materials and oxide additives, it is TiO 2 :Al 2 o 3 : Fe 2 o 3 : SiO 2 =42.5%: 42.5%: 6%: 9%. Other processes are with embodiment 1. The performance of the obtained product is shown in Table 2.

[0032] Table 2

[0033]

Embodiment 3

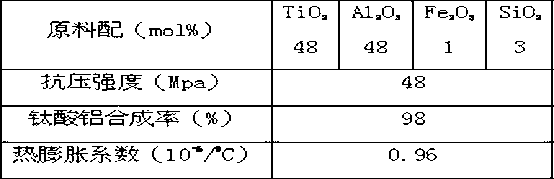

[0035] Change the ratio of raw materials and oxide additives to TiO 2 :Al 2 o 3 : Fe 2 o 3 : SiO 2 =46%:46%:3%:5%. Other processes are with embodiment 1. The properties of the obtained product are shown in Table 3.

[0036] table 3

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com