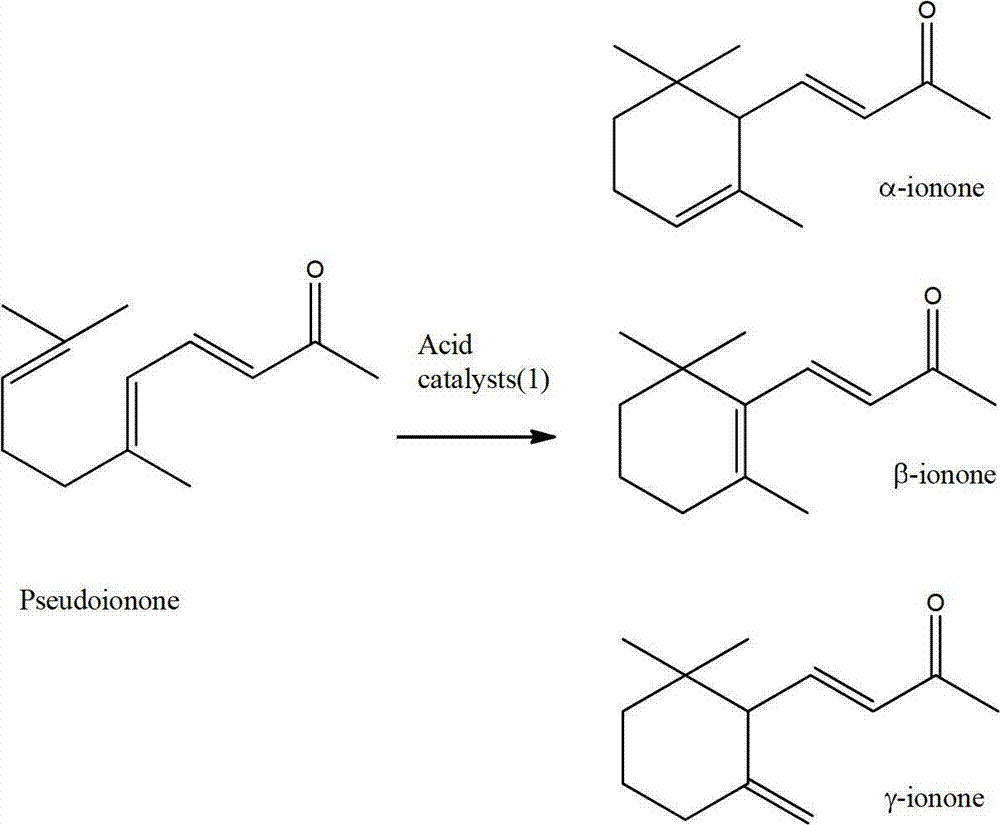

Method for preparing ionone by using super-strong acid or super-strong-acid-based ionic liquid as catalyst

An ionone and pseudoionone technology, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of low catalyst yield, large catalyst usage, etc., and achieve high reaction conversion rate and Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

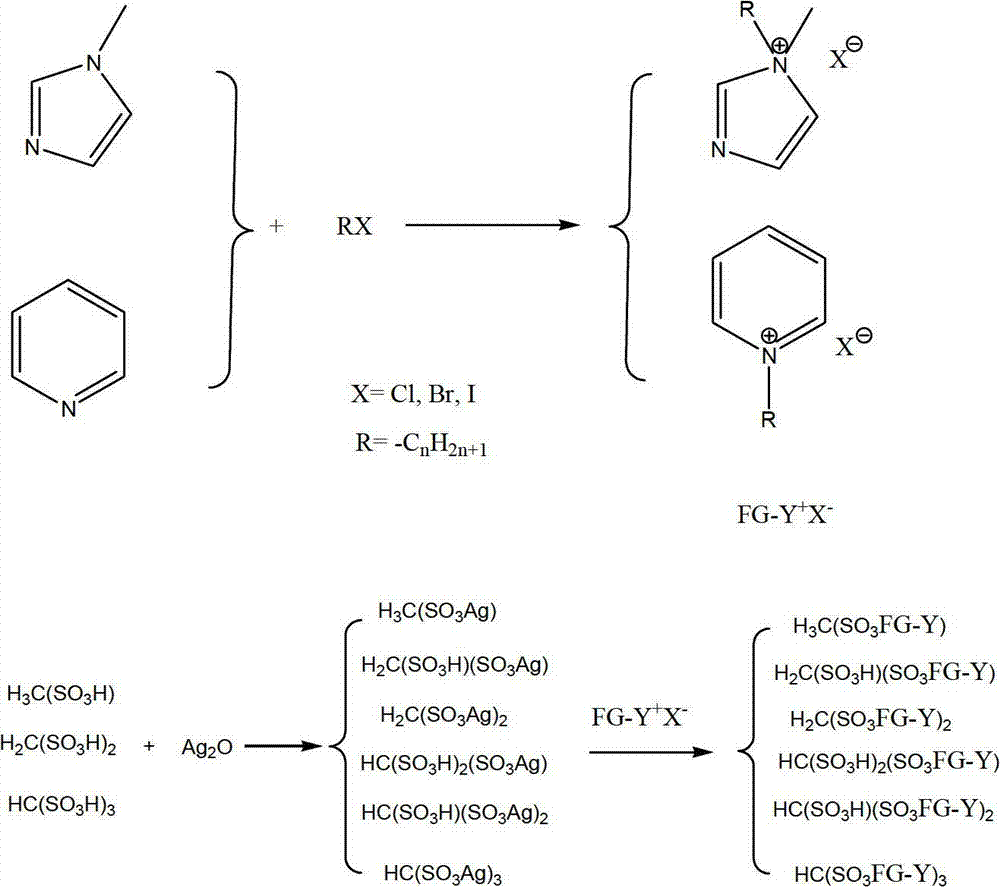

[0019] The preparation of embodiment 1 catalyst

[0020] Both methanesulfonic acid and methanedisulfonic acid involved in the present invention can be purchased through commercial channels.

[0021] 1. Referring to the existing literature (Sustainability 2009.1.161-168) to synthesize methanetrisulfonic acid superacid solid

[0022] 1. Slowly add acetone dropwise to 65% oleum at low temperature and constant temperature, and control the temperature at -2°C±1°C;

[0023] 2. After the dropwise addition is completed, keep the temperature at low temperature for 30 minutes;

[0024] 3. Move the reaction solution to a water bath at 85°C and keep it warm for 3 hours;

[0025] 4. Slowly add the reaction solution to 500ml of ice-cold distilled water, and refrigerate the solution overnight;

[0026] 5. Add KOH caustic soda to the solution to make the pH of the reaction solution around 7.0;

[0027] 6. Pour the reaction solution into a 3L beaker, add distilled water, and refrigerate fo...

Embodiment 2-7

[0038] Embodiment 2-7 Pseudo-ionone synthesizes ionone

[0039]Add 2g of dry methanetrisulfonic acid solid in a three-necked flask, then add 100ml of gasoline, keep stirring at a temperature of 60°C, add 6.5g of pseudo-ionone while stirring, and react at a temperature of 60°C for 1.3 hours, After the reaction, the methyltrisulfonic acid solid catalyst was separated by filtration, then gasoline was separated in a rotary evaporator, and finally the target products α-ionone and β-ionone were separated by vacuum distillation. The conversion rate of raw materials is above 99%, and the yield of ionone is 92%.

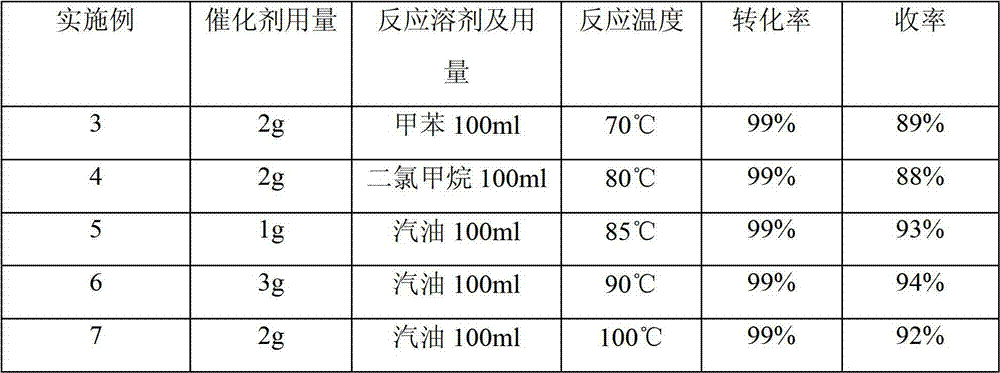

[0040] With reference to the above-mentioned synthetic method, select different methyltrisulfonic acid catalyst consumptions, reaction solvent and reaction temperature, the conversion rate and the yield obtained are shown in the following table:

[0041]

Embodiment 8-13

[0043] Referring to the above synthesis method, select different acid catalysts, use gasoline as a solvent, and see the following table for the reaction conversion rate and yield at a temperature of 80°C:

[0044] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com