Refining method of vitamin C

A refining method and vitamin technology, which is applied in the fields of medicine and chemical industry, can solve the problems of high purity, easy oxidation, complicated operation, etc., and achieve the effects of stable quality, reduced oxidation, and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

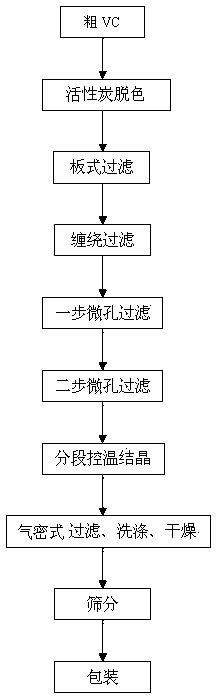

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.8 tons of crude VC in 3.5m 3 Add 3 times the mass of purified water to the dissolution tank, and rapidly raise the temperature to 85°C under the condition of a stirring speed of 60 rpm to fully dissolve the crude VC, add 2% (W / W) medical powder activated carbon, and decolorize for 40 minutes. The decolorized vitamin C solution was filtered through a plate filter of 0.3m activated clay filter cake, 1 textile fiber sand core with a filtration precision of 2μm, 10 polypropylene filter membranes with a filtration precision of 0.3μm, and 15 filtration precision 0.1 Filter through a μm polypropylene filter. The filtrate obtained after the four-stage filtration is crystallized by segmental temperature control. First, the crystallizer is preheated with hot purified water, the accumulated water is drained, and the air in the crystallization tank is replaced with nitrogen gas. The temperature is lowered while feeding, and the first hour 80~45℃, 45~30℃ in the second hour,...

Embodiment 2

[0033] Weigh 1.5 tons of crude VC at 3.5m 3 Add purified water of the same quality to the dissolution tank, and rapidly raise the temperature to 80°C at a stirring speed of 75 rpm to fully dissolve the crude VC, add 3% (W / W) medical powder activated carbon, and decolorize for 20 minutes. The decolorized vitamin C solution was filtered through a plate filter of 0.5m activated clay filter cake, 2 textile fiber sand cores with a filtration precision of 3μm, 12 polypropylene filter membranes with a filtration precision of 0.3μm and 12 filtration precision 0.2 Filter through a μm polypropylene filter. The filtrate obtained after the four-stage filtration is crystallized by segmental temperature control. First, the crystallizer is preheated with hot purified water, the accumulated water is drained, and the air in the crystallization tank is replaced with nitrogen gas. The temperature is lowered while feeding, and the first hour 80~45℃, 45~30℃ in the second hour, 30~18℃ in the third...

Embodiment 3

[0038] Weigh 1.2 tons of crude VC in 3.5m 3 Add 2 times the mass of purified water to the dissolution tank, and rapidly raise the temperature to 60°C at a stirring speed of 120 rpm to fully dissolve the crude VC, add 5% (W / W) medical powdered activated carbon, and decolorize for 10 minutes. The decolorized vitamin C solution was filtered through a plate filter of 0.1m activated clay filter cake, 3 textile fiber sand cores with a filtration precision of 1μm, 15 polypropylene filter membranes with a filtration precision of 0.5μm and 10 filtration precisions of 0.3 Filter through a μm polypropylene filter. The filtrate obtained after the four-stage filtration is crystallized by segmental temperature control. First, the crystallizer is preheated with hot purified water, the accumulated water is drained, and the air in the crystallization tank is replaced with nitrogen gas. The temperature is lowered while feeding, and the first hour 80~45℃, 45~30℃ in the second hour, 30~18℃ in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com