Application of chitosan to yolk fatty deposition and derosination technology

A technology of chitosan and chitosan solution, applied in the preparation method of peptides, from egg immunoglobulin, organic chemistry, etc., can solve the problems of large amount of degreasing reagents, high loss rate of IgY, difficult to remove, etc. Achieve the effects of low environmental conditions, less IgY loss, and less reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

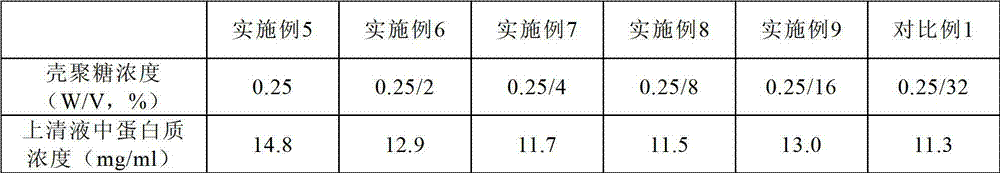

Examples

Embodiment 1

[0024] In an environment of 4-50°C, take the yolk out of the egg, break the yolk membrane, measure 100m1 of the yolk stock solution, and place it in a 500m1 beaker. Accurately weigh 0.4g of chitosan and dissolve it in 100m1 of 1% (V / V) acetic acid solution, stir until completely dissolved to obtain a chitosan solution, then pour the chitosan solution into the egg yolk stock solution and mix well, let stand Precipitation for 24h. The precipitated mixed solution is divided into two layers, the bottom precipitate is egg yolk lipid component, and the supernatant is egg yolk water-soluble component, that is, a mixed solution containing immunoglobulin IgY.

Embodiment 2

[0026] In an environment of 4-50°C, take the yolk out of the egg, break the yolk membrane, measure 100m1 of the yolk stock solution, put it in a 500m1 beaker, add 100m1 distilled water to dilute, mix well, and make the yolk dilution. Accurately weigh 0.6g of chitosan and dissolve it in 100m1 of 1% (V / V) acetic acid solution, and stir until completely dissolved. Pour the chitosan solution into the egg yolk dilution and stir well, then let the solution stand for 3 hours. The precipitated mixed solution is divided into two layers, the bottom precipitate is the egg yolk lipid component, and the supernatant is the egg yolk water-soluble component, that is, the mixed solution of immunoglobulin IgY and other proteins.

Embodiment 3

[0028] In an environment of 4~50°C, after taking the yolk out of the egg, break the yolk membrane, measure 100m1 of the yolk stock solution, add 0.8g chitosan, 300m1 of 1% (V / V) acetic acid solution, stir well, and then put The mixture was allowed to settle overnight. The precipitated mixed solution is divided into two layers, the bottom precipitate is the egg yolk lipid component, and the supernatant is the egg yolk water-soluble component, that is, the mixed solution of immunoglobulin IgY and other proteins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com