Method for preparing hesperetin monoglucoside by fermentation, enzymolysis, extraction and coupling

A technology of monoglucoside and hesperetin, which is applied in the field of conversion and extraction of biochemical substances, can solve the problems of high price, easy degradation, and low yield of hesperidinase, and achieve reduced production costs, improved conversion rates, and improved product quality. yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing hesperetin monoglucoside by coupling fermentation-enzymolysis-extraction, the method is carried out according to the following steps:

[0047] 1) Preparation of culture medium: the components of the following two types of culture medium and the mass percentage of each component are as follows:

[0048] a. Bacteria activation culture medium: 3% glucose, 0.3% beef extract, K 2 HPO 4 ·3H 2 O 0.3%, MgSO 4 ·7H 2 O 0.05%, FeSO 4 ·7H 2 O 0.01%, make up to 100% with water, and reserve;

[0049] b. Production of fermentation broth: 3% sucrose, 0.3% beef extract, K 2 HPO 4 ·3H 2 O 0.3%, MgSO 4 ·7H 2 O 0.05%, FeSO 4 ·7H 2 O 0.01%, make up to 100% with water, and reserve;

[0050] 2) Preparation of strain seed solution: Fusarium nivale ( Fusarium nivale ) HESPER strain CGMCC No.6238 is the strain, pick a small amount of strains in the strain activation culture medium, activate and cultivate at 30 ℃, 150 r / min for 48 h, until the number ...

Embodiment 2

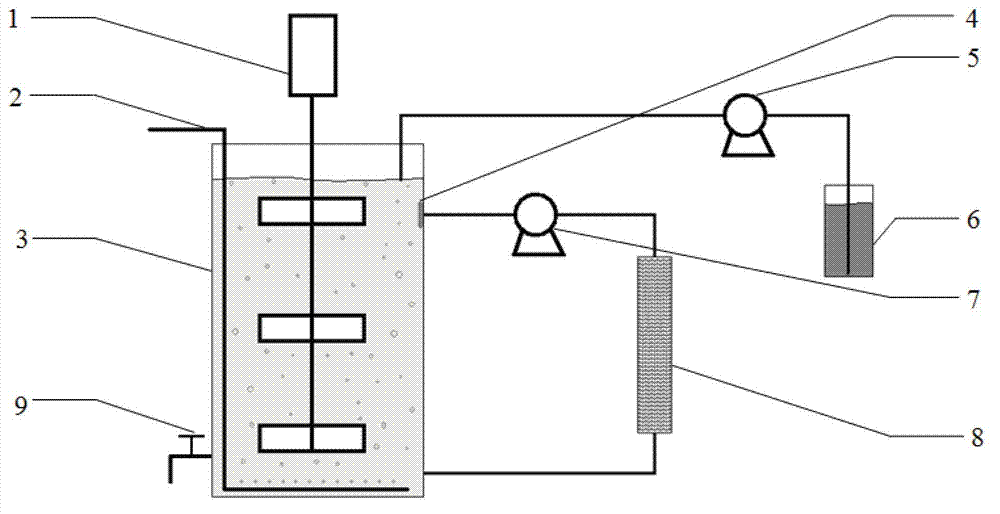

[0058] In this example, step 2) preparation of strain seed liquid: culture speed is 170 r / min, activation time is 36 h; step 3) preparation of fermentation liquid for hesperidin production: strain seed liquid: production fermentation culture liquid: Hesperidin = 1.5mL: 75mL: 0.75g; Step 4) Cultivation of Hesperidin Production Fermentation Broth: Sterile air input rate is 2.5 L / min, stirring speed is 50 r / min; Step 5) Resin of Fermentation Broth Adsorption, reflux, discharge and feeding: the macroporous resin adopts the AB-8 model, the reflux rate of the fermentation broth is 2 column volumes / h, the material discharge interval is 20 h, the material discharge is 20%, and the feed is 20% at the same time ; Step 6) Elution and collection of resin: the amount of water washing is 5 column volumes / h, the ethanol concentration is 85%, and the ethanol elution rate is 1 column volume / h; the remaining steps and processes are the same as in Example 1.

[0059]

Embodiment 3

[0061] In this example, step 2) preparation of strain seed liquid: culture speed is 180 r / min, activation time is 24 h; step 3) preparation of fermentation liquid for hesperidin production: strain seed liquid: production fermentation culture liquid: Hesperidin = 2mL: 100mL: 1g; Step 4) Cultivation of Hesperidin Production Fermentation Broth: Input rate of sterile air was 5 L / min, stirring speed was 80 r / min; Step 5) Resin adsorption of Fermentation Broth, Reflux, discharge and feeding: the macroporous resin adopts the D101-I model, the reflux rate of the fermentation broth is 4 column volumes / h, the material discharge interval is 30 h, the material discharge is 30%, and the feed is 30% at the same time; steps 6) Resin elution and collection: the amount of water washing is 8 column volumes / h, the ethanol concentration is 100%, and the ethanol elution rate is 2 column volumes / h; the rest of the steps and processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com