Preparation method of nano-palladium or palladium-nickel alloy catalyst having three-dimensional porous structure

An alloy catalyst and three-dimensional porous technology, applied in the field of electrochemistry, can solve the problems of complex template removal process and unfavorable reactant transport, and achieve the effect of easy preparation, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Carry out pretreatment on the glassy carbon electrode, including polishing, ultrasonic, electrochemical cleaning, etc. The specific method is the same as step 1 of the comparative example.

[0035] 2. Prepare the solution required for electrodeposition, including 20 mM PdCl 2 , 0.5 M H 2 SO 4 , 0.1 M NH 4 Cl.

[0036] 3. Three-dimensional porous Pd was obtained by electrodeposition on an electrochemical workstation using a three-electrode system, and the specific conditions were deposition at a potential of -4 V for 60 s.

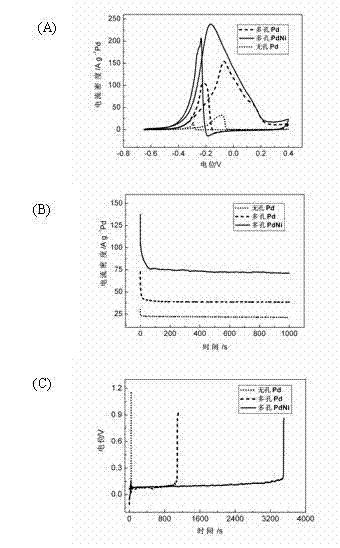

[0037] 4. The prepared catalyst was tested for the electrocatalytic oxidation of methanol.

[0038] 5. Result description:

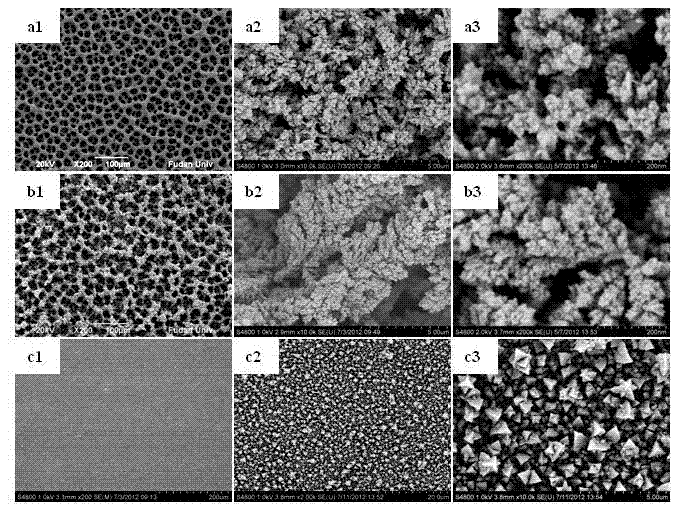

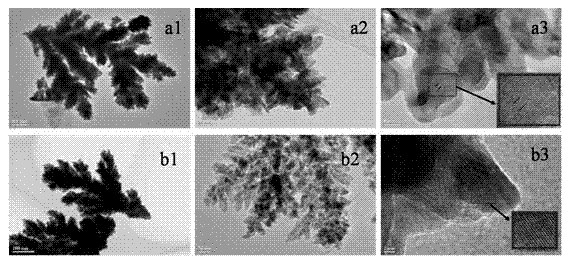

[0039] (a) As can be seen from the schematic diagrams in Figure 1a1-Figure 1a3, through this simple method, we have obtained a Pd catalyst with a porous structure. Figure 1a1 shows that the catalyst has regular micron-scale pores, which are conducive to The transport of reactants reduces the diffusion effect; Figure 1a...

Embodiment 2

[0043] 1. Carry out pretreatment on the glassy carbon electrode, including polishing, ultrasonic, electrochemical cleaning, etc. The specific method is the same as step 1 of the comparative example.

[0044] 2. Prepare the solution required for electrodeposition, including 20 mM PdCl 2 , 0.1 M NiCl 2 , 0.5 M H 2 SO 4 , 0.1 M NH 4 Cl.

[0045] 3. Three-dimensional porous PdNi was obtained by electrodeposition on an electrochemical workstation with a three-electrode system, and the specific conditions were deposition at a potential of -4 V for 60 s.

[0046] 4. The prepared catalyst was tested for the electrocatalytic oxidation of methanol.

[0047] 5. Result description:

[0048] (a) It can be seen from the schematic diagrams in Figure 1b1-Figure 1b3 that through this simple method, we have obtained a PdNi catalyst with a porous structure. Compared with the catalyst, the pore wall is relatively rough; Figure 1b2 shows that the pore wall is composed of porous dendrite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com