A copper/silver-based electrode based on a conductive bacterial cellulose composite film

A bacterial cellulose and composite electrode technology, which is applied in battery electrodes, organic compound/hydride/coordination complex catalysts, circuits, etc., can solve the problem of reduced efficiency, inability to tightly combine catalysts and substrate materials, and no nano-network structure To achieve the effect of increasing the contact specific surface area, improving Faraday efficiency, and multiple catalytic active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

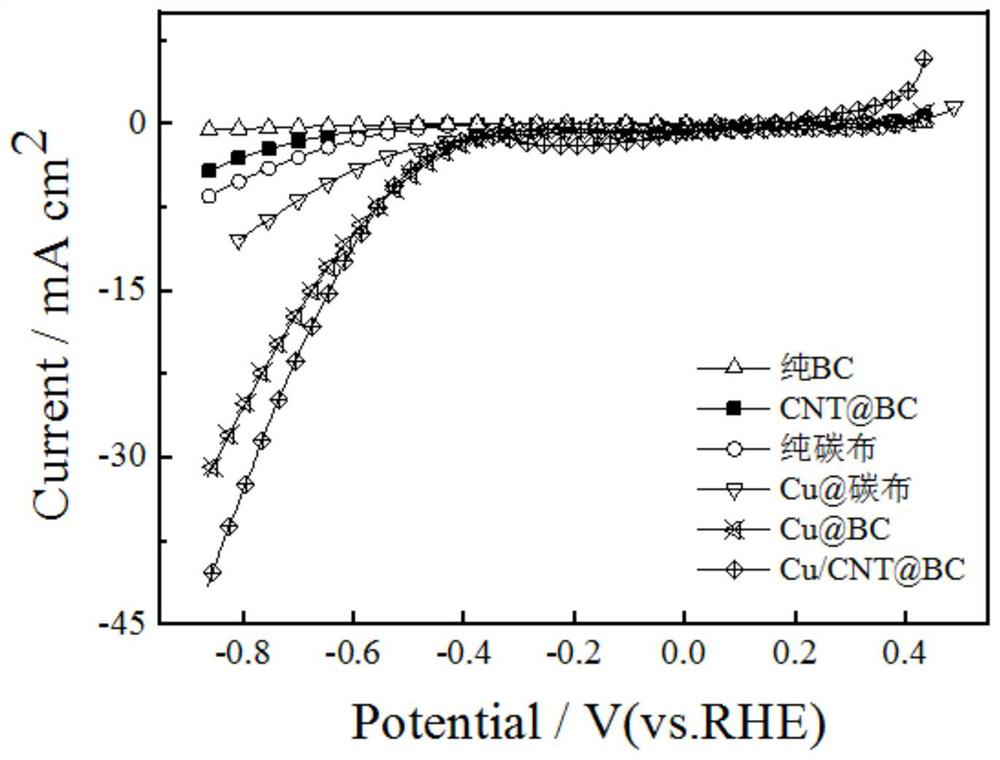

[0062] The copper-based electrode for electrochemical catalysis in this example is composed of a static in-situ cultured CNT@BC composite film loaded nano-copper electrode. The electrode is synthesized by an in-situ catalytic reduction method, and its preparation method is as follows:

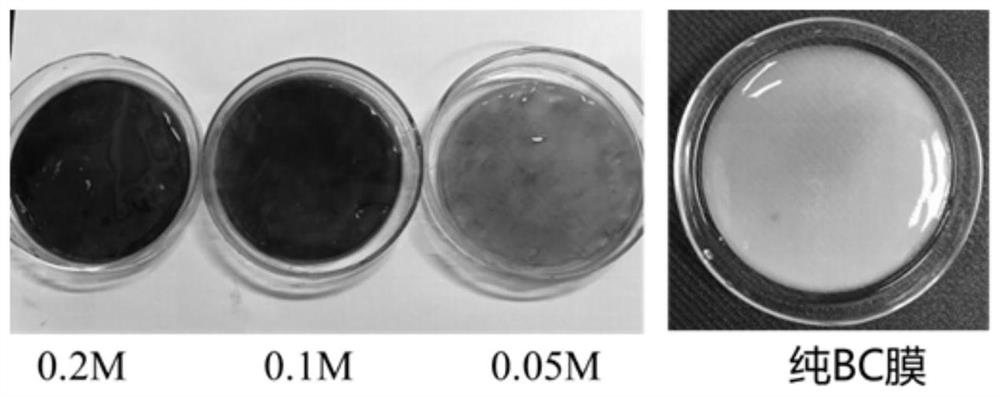

[0063] (1) With Acetobacter xylinum as the strain (Komagataeibacter xylinusATCC23770, the same below), adding molar concentrations of 0.05M, 0.1M, 0.2M carbon nanotubes (industrial grade multi-walled carbon nanotubes, >90%, inner diameter: 5- 15nm, outer diameter: >50nm, length: 10-20 μ m, 50g, Aladdin Reagent (Shanghai) Co., Ltd., other examples are the same) respectively with fermentation medium (50g / L glucose, C 6 h 12 o 6 , AR, Sinopharm Reagent Co., Ltd.; 5g / L tryptone, BR, Sinopharm Reagent Co., Ltd.; 3g / L yeast powder, BR, Sinopharm Reagent Co., Ltd., the same below) mixed solution (in-situ static constant temperature culture 2 -3 days, take out the CNT@BC composite membrane and place ...

Embodiment 2

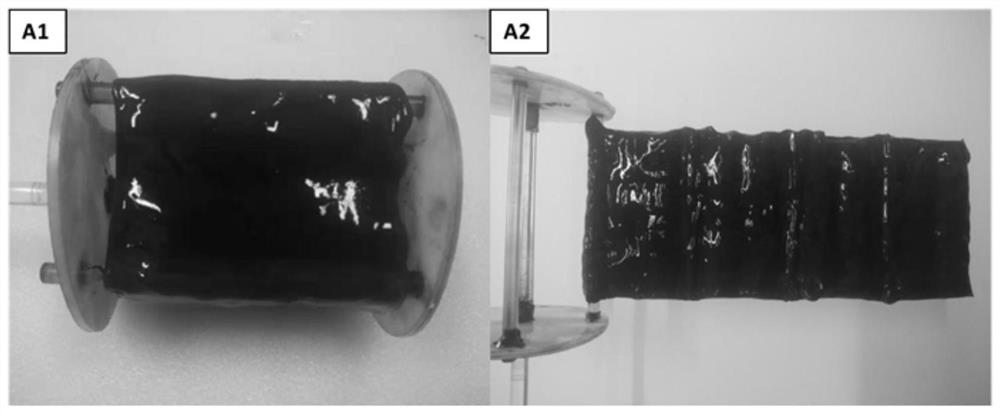

[0076] The silver-based electrode used for electrochemical catalysis in this embodiment is composed of a CNT@BC composite film supported by a dynamic in-situ cultured nano-copper electrode. The electrode is synthesized by an in-situ catalytic reduction method, and its preparation method is as follows:

[0077] (1) With Acetobacter xylinum as the strain, add 200 mL of a mixed solution of carbon nanotubes and medium with a concentration of 0.1M in a horizontal drum reactor, add two drops of Tween 80 as a dispersant with a rubber dropper, and mix well Cultivate for 24h. In the aseptic workbench, continue to add 200ml of 0.1M CNT and fermentation broth mixed medium into the glass fermenter through a peristaltic pump for subsequent fermentation and culture for 24 hours. Take out the CNT@BC composite membrane and place it in sodium hydroxide solution, treat it at 80°C for 2-4 hours, take it out, rinse it with deionized water until neutral, and obtain the CNT@BC composite membrane. ...

Embodiment 3

[0083] The copper-based electrode used for electrochemical catalysis in this example is composed of impregnated and cultured CNT@BC composite film loaded nano-copper electrode. The electrode is synthesized by in-situ catalytic reduction method, and its preparation method is as follows:

[0084] (1) Use Acetobacter xylinum as the bacterial species, prepare bacterial cellulose pure film by static culture for 2-4 days, take out the pure film and place it in sodium hydroxide solution, treat it at 80°C for 2-4h, take it out, and use it The pure BC membrane was obtained after rinsing with deionized water to neutrality.

[0085] (2) The pure BC membrane was dynamically impregnated with a carbon nanotube aqueous solution with a concentration of 0.1M, oscillated dynamically in a constant temperature oscillator at 30°C for 24 hours, and the CNT@BC composite membrane was obtained after taking it out. Multi-walled carbon nanotubes can be dispersed for 30 minutes with an ultrasonic cleanin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com