A kind of doped nickel-iron phosphide-based three-dimensional ultra-thin nanosheet material and its preparation method and application

A nickel-iron-based, nano-sheet technology, applied in nanotechnology, electrolytic components, electrodes, etc., can solve problems such as difficult matching, large overpotential of catalyst materials, and poor electron conversion efficiency, so as to improve performance and high-efficiency electrocatalytic hydrogen evolution analysis Oxygen performance, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

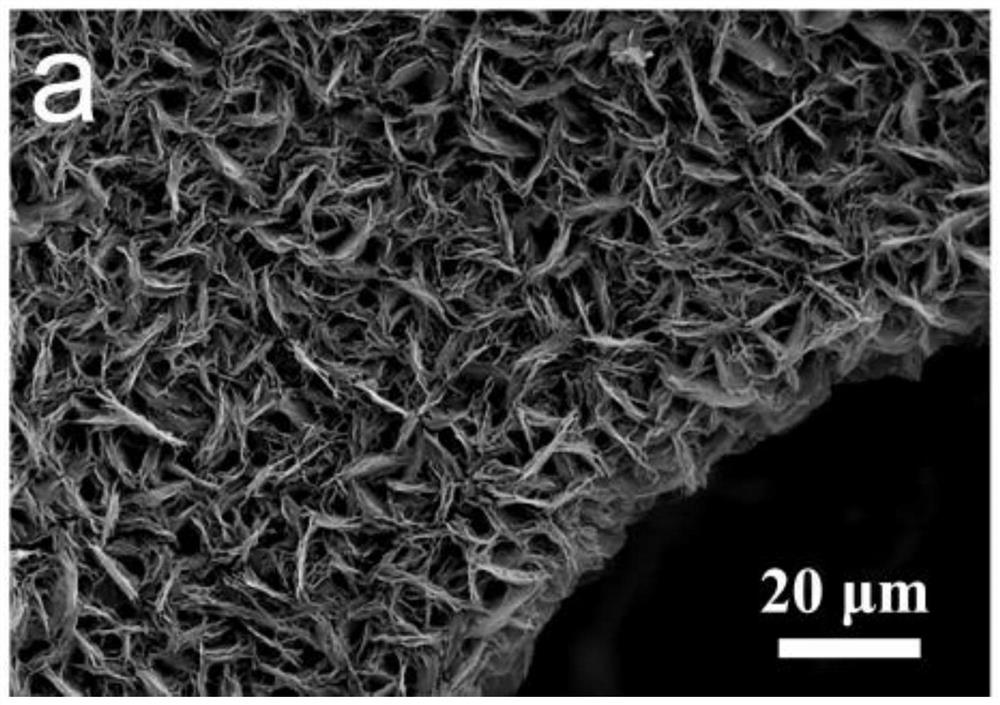

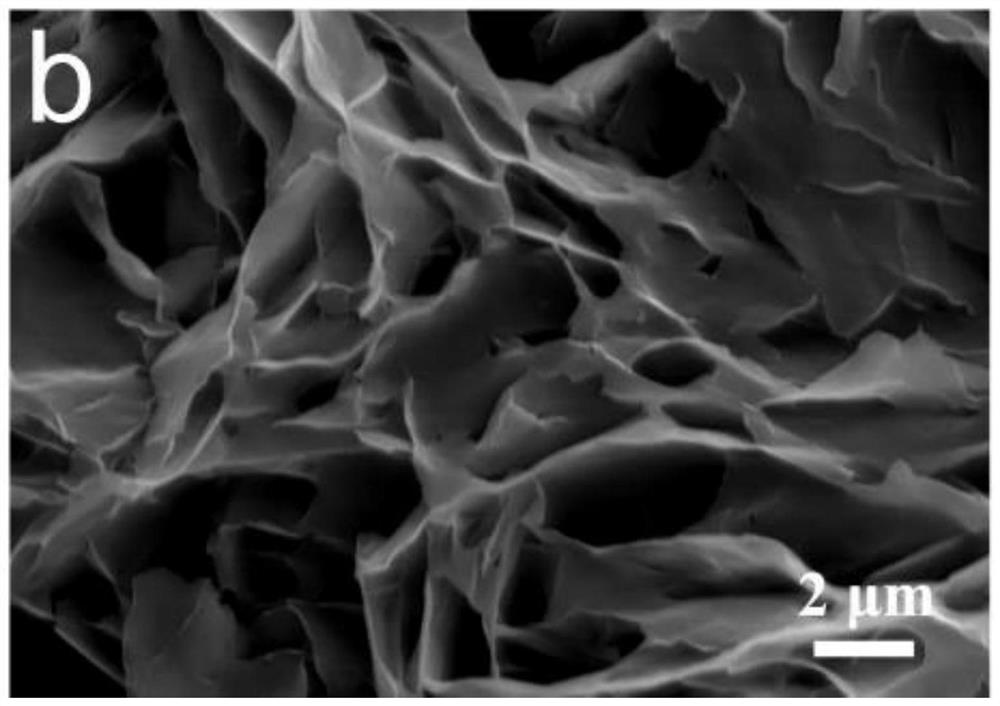

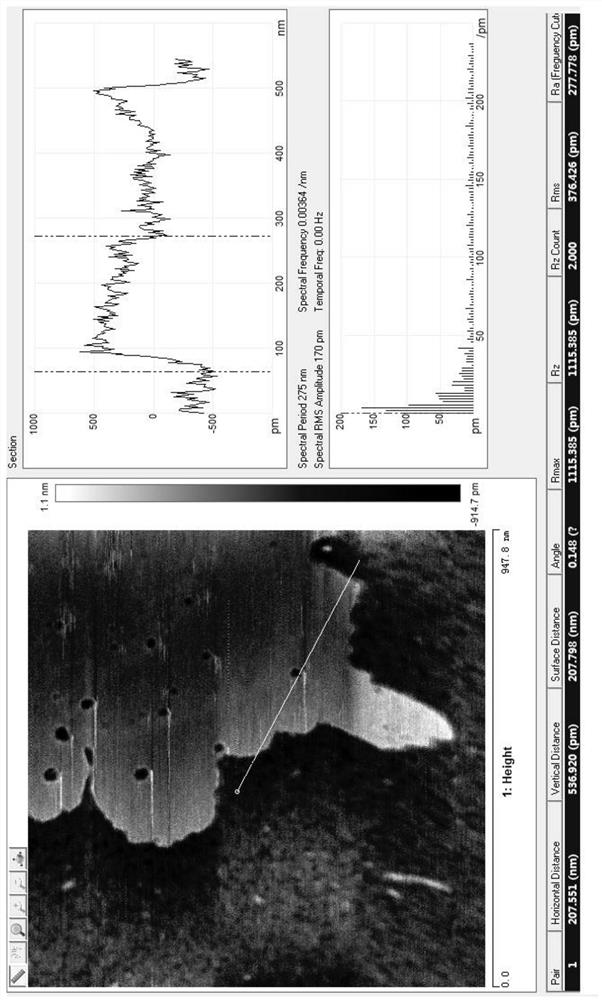

[0045] Embodiment 1: The preparation method of the doped nickel-iron phosphide-based three-dimensional ultra-thin nanosheet material of this embodiment is carried out according to the following steps:

[0046] 1. Pretreatment of foamed nickel: First, ultrasonically clean the foamed nickel with a cut size of 3cm×3cm in 50mL of acetone, 50mL of ethanol and 50mL of deionized water for 5 minutes, and then dry it in a vacuum drying oven at a temperature of 80°C. Nickel foam that removes organic matter and oxide film can be obtained;

[0047] 2. Add 2 mmol of ferric nitrate, 1 mmol of zinc acetate, 6 mmol of urea and 6 mmol of hexamethylenetetramine into 30 mL of ethanol, and stir for 3 hours at a stirring speed of 100 r / min to obtain a mixed solution;

[0048] 3. Transfer the mixed solution obtained in step 2 to a 50mL reactor, and then put the nickel foam pretreated in step 1 into the reactor for solvothermal reaction. The temperature of the solvothermal reaction is 150°C, and the...

Embodiment 2

[0058] Embodiment 2: The preparation method of the doped nickel-iron phosphide-based three-dimensional ultra-thin nanosheet material of this embodiment is carried out according to the following steps:

[0059] 1. Pretreatment of foamed nickel: First, ultrasonically clean the foamed nickel with a cut size of 3cm×3cm in 50mL of acetone, 50mL of ethanol and 50mL of deionized water for 15 minutes, and then dry it in a vacuum drying oven at a temperature of 80°C. Nickel foam that removes organic matter and oxide film can be obtained;

[0060] 2. Add 2mmol of iron acetate, 1mmol of manganese acetate, 7mmol of urea and 7mmol of hexamethylenetetramine into 30mL of isopropanol, and stir for 2h at a stirring speed of 150r / min to obtain a mixed solution;

[0061] 3. Transfer the mixed solution obtained in step 2 to a 50mL reactor, and then put the nickel foam pretreated in step 1 into the reactor for solvothermal reaction. After cooling to room temperature, the precursor is obtained;

[...

Embodiment 3

[0065] Embodiment 3: The preparation method of the doped nickel-iron phosphide-based three-dimensional ultra-thin nanosheet material of this embodiment is carried out according to the following steps:

[0066] 1. Pretreatment of foamed nickel: First, ultrasonically clean the foamed nickel with a cut size of 2cm×2.5cm in 50mL of acetone, 50mL of ethanol and 50mL of deionized water for 5 minutes, and then dry it in a vacuum drying oven at a temperature of 60°C , the nickel foam that removes organic matter and oxide film can be obtained;

[0067] 2. Add 3mmol ferric nitrate, 1mmol zinc acetate, 10mmol urea and 6mmol hexamethylenetetramine to 30mL water and ethanol mixture, the volume ratio of water and ethanol in the water and ethanol mixture is 1:1; Stir for 2 hours at a speed of 150r / min to obtain a mixed solution;

[0068] 3. Transfer the mixed solution obtained in step 2 to a 50mL reactor, and then put the nickel foam pretreated in step 1 into the reactor for solvothermal re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com