Porous noble metal-based membrane electrode as well as preparation method and application thereof

A precious metal and pore technology, applied in the direction of electrodes, battery electrodes, metal material coating technology, etc., can solve the problems of complicated treatment process, high loss of precious metals, difficulty in removing intermediate reactants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A. Soak the graphite fiber cloth in 0.5mol / L H at 30°C 2 SO 4 In the solution for 5 minutes, after cleaning and dehydrating with deionized water and absolute ethanol at room temperature, then dry at 50°C for 10 minutes under normal pressure to obtain a pretreated carbonaceous carrier;

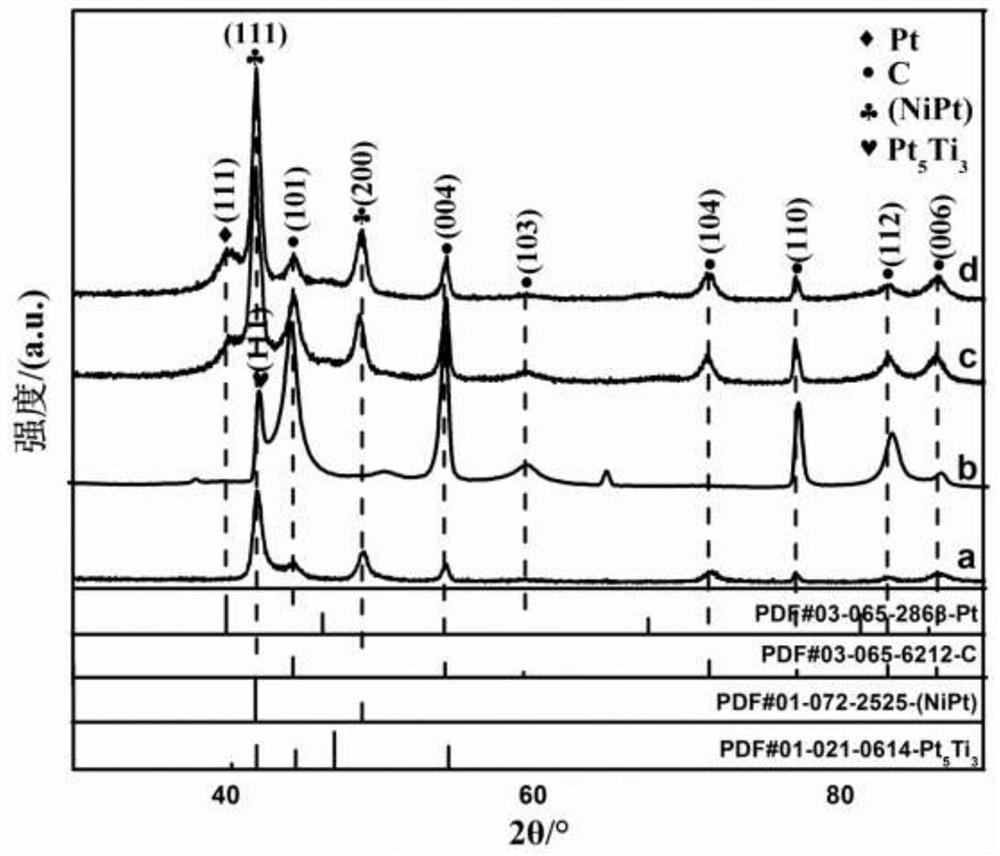

[0059] B. Place the carbonaceous carrier obtained in step A in an ion beam sputtering device, heat it to 350°C and keep it warm at 8.0×10 - 3 In the vacuum of Pa, 7.5 sccm of high-purity Ar was introduced, the sputtering screen pressure was controlled to 2.5kV, and the beam current was 70mA. The ion beam sputtered the Pt target containing Ni for 20min, and then naturally cooled to room temperature in the same vacuum degree. Obtain carbon-supported PtNi alloy catalyst;

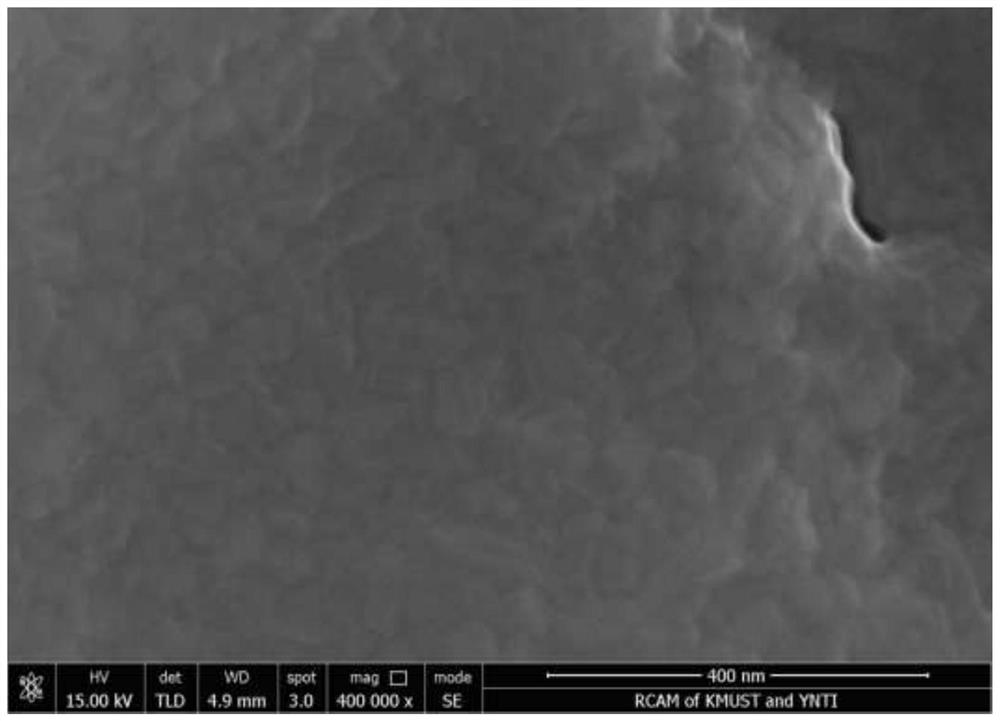

[0060] C. Immerse the carbon-supported PtNi composite catalyst obtained in step B in an electrolytic cell with a 0.5mol / L HCl solution at 60°C for 60 minutes of electrochemical corrosion; then wash with deionized water...

Embodiment 2

[0064] A. Soak the graphite fiber cloth in 0.8mol / L H at 40°C 2 SO 4 In the solution for 10 minutes, after cleaning and dehydrating with deionized water and absolute ethanol at room temperature, and then drying at 60°C for 20 minutes under normal pressure to obtain a pretreated carbonaceous carrier;

[0065] B. Place the carbonaceous carrier obtained in step A in an ion beam sputtering device, heat it to 250°C and keep it warm at 1.5×10 - 2 In a vacuum of Pa, 8.5 sccm of high-purity Ar is introduced, the sputtering screen pressure is 2.0kV, the beam current is 50mA, the ion beam sputters the Pt target containing Ti for 30min, and then it is naturally cooled to room temperature in the same vacuum degree. Obtain carbon-supported PtTi alloy catalyst;

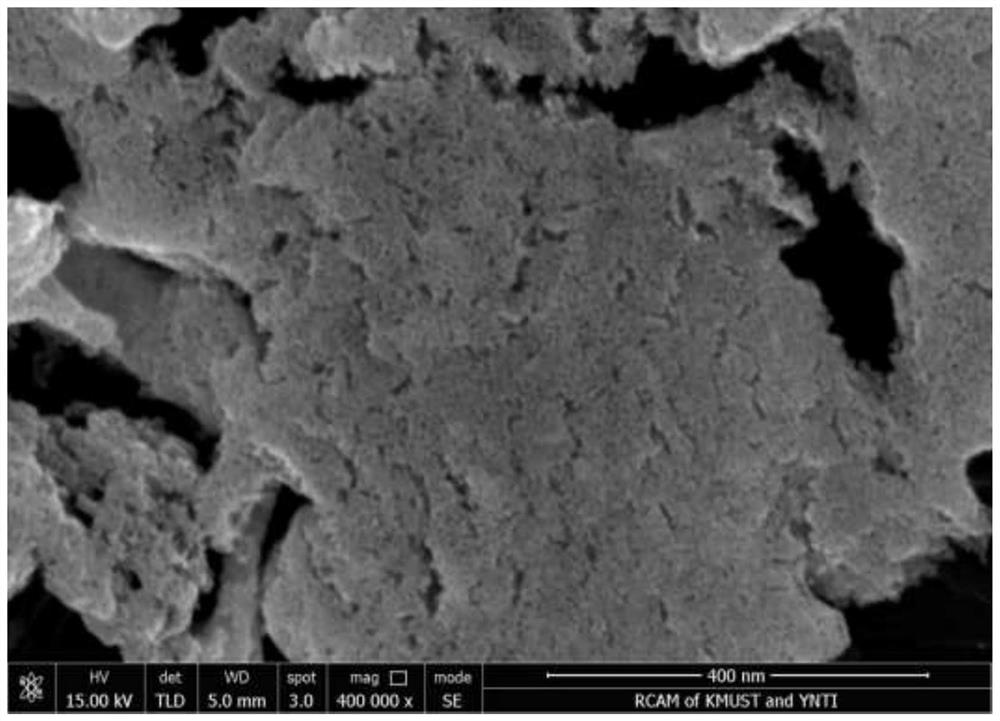

[0066] C. Immerse the carbon-supported PtTi composite catalyst obtained in step B in an electrolytic cell equipped with a 1.0mol / L HCl solution at 50°C for 90 minutes of electrochemical corrosion, during which the ultrasonic pow...

Embodiment 3

[0070]A. Immerse conductive carbon paper in 1.0mol / L H at 50°C 2 SO 4 In the solution for 5 minutes, after cleaning and dehydrating with deionized water and absolute ethanol at room temperature, then dry at 80°C for 15 minutes under normal pressure to obtain a pretreated carbonaceous carrier;

[0071] B. Place the carbonaceous carrier obtained in step A in an ion beam sputtering device, heat it to 350°C and keep it warm at 1.0×10 - 2 In the vacuum of Pa, 8.0sccm high-purity Ar was introduced, the sputtering screen pressure was controlled to 3.0kV, and the beam current was 100mA. The ion beam sputtered the Pt target containing Ni for 15min, and then cooled naturally to room temperature in the same vacuum degree. Obtain carbon-supported PtNi alloy catalyst;

[0072] C. Immerse the carbon-supported PtNi composite catalyst obtained in step B in an electrolytic cell equipped with a 0.2mol / L HCl solution at 40°C for 30 minutes of electrochemical corrosion, during which the ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com