Neutron tube with drive-in target

A technology of neutron tube and ion source, which is applied in the direction of DC voltage accelerator to achieve the effect of ensuring electrical parameters, long service life and good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

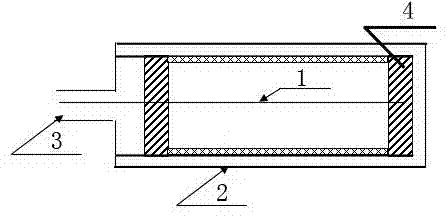

[0020] Self-contained target neutron tube, composed of ion source, acceleration system, target and deuterium-tritium storage. The ion source is a cold cathode 2 Penning ion source, which consists of an anode 1, a cathode 2, an output cathode 3 and a samarium cobalt magnet 4. The cathode 2 is formed of a convex molybdenum material, and the distance between it and the anode 1 is 2 mm. The output cathode 3 is in the shape of a plane disc. The acceleration system is a single-gap acceleration system, which is composed of the output cathode 3 and the acceleration electrode in the ion source. Wherein the aperture of the output cathode 3 is 4-5mm. The target is a conical concave oxygen-free copper material. The getter in the deuterium-tritium storage is zirconium-graphite material.

Embodiment 2

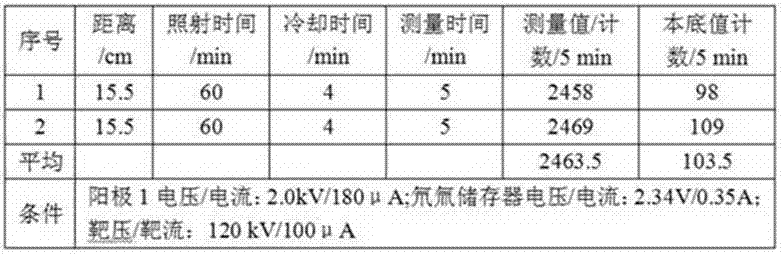

[0022] In a room temperature environment, the neutron yield of the self-targeting neutron tube described in Example 1 was detected by a copper activation method. The results are shown in the table below.

[0023]

[0024] According to the above method and test data, the neutron yield of the neutron tube under the condition of 120 kV / 100μA is 2.9×10 8 n / s.

Embodiment 3

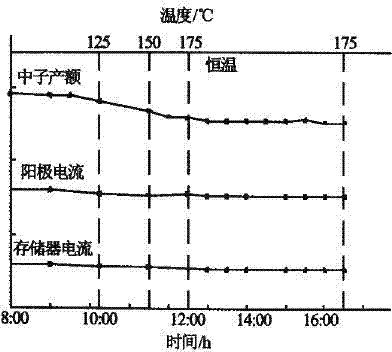

[0026] The self-targeting neutron tube described in Example 1 was subjected to a high temperature experiment at 175°C for 8.5 hours. During the experiment, by adjusting the voltage or current value of the deuterium-tritium storage, keeping the target pressure and target current value unchanged (that is, the target voltage is 120 kV, the target current is 100 μA), and the neutron yield and the change of the anode 1 current are observed. See the experimental curve figure 2 . Depend on figure 2 It can be seen that in the first 1 h, that is, when the temperature is below 50°C, the neutron yield changes little. When the temperature is in the range of 60~175℃, the neutron yield shows a downward trend as the temperature gradually rises. When the temperature rises to 175°C and enters the constant temperature zone, the neutron yield also tends to be stable as the temperature stabilizes. The anode 1 current has been very stable throughout the experiment, with a maximum variation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com