Novel CMOS-MEMS compatible uncooled infrared sensor pixel level packaging method

An uncooled infrared and sensor pixel technology, which is applied in the field of new CMOS-MEMS compatible uncooled infrared sensor pixel level packaging, can solve the problems of poor reliability and abnormal operation of the detector, achieve high reliability and realize mass application , The effect of reducing packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in conjunction with the accompanying drawings.

[0017] The purpose and technical solutions of the present invention will be described in detail below in conjunction with specific examples.

[0018] Such as figure 1 As shown, the device wafer has a readout circuit, a detector sensitive element 2 , a first sacrificial layer and a degasser 8 .

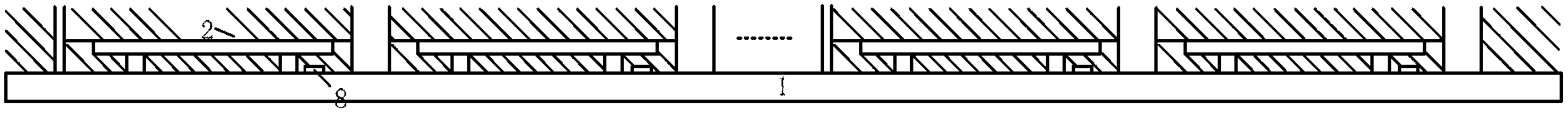

[0019] The first sacrificial layer 3 of the device wafer 1 after the processing of the sensitive element 2 is not released, and it is different from the usual processing process in that the degassing agent 8 must be prepared in advance in the process of making the detector sensitive element 2, so The material of the degassing agent is titanium; the second sacrificial layer 3' is prepared on the first sacrificial layer 3, such as figure 2 As shown, the height of the first sacrificial layer 3 and the second sacrificial layer 3' is 2.5um, and the material of the first sacrificial lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com