Magnetic door seal made of thermoplastic polyolefin materials and for refrigerator and freezer and preparation method thereof

A thermoplastic polyolefin and door seal technology, which is applied in lighting and heating equipment, applications, household appliances, etc., can solve the problem of affecting the service life of PVC rubber sleeves, low elongation at break of PVC rubber sleeves, shortening the service life of PVC rubber sleeves, etc. Problems, good anti-aging and migration resistance, improved dispersion effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

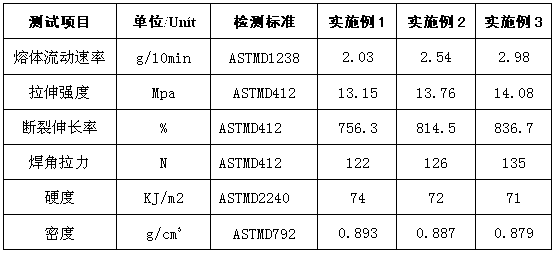

Embodiment 1

[0043] The thermoplastic polyolefin elastomer door seal rubber sleeve of the magnetic door seal is composed of the following components in parts by weight:

[0044] POE 40 copies

[0045] 10 parts naphthenic oil

[0046] 30 parts polypropylene

[0047] SEBS 15 copies

[0048] PS 15 copies

[0049] PE wax 0.8 parts

[0050] Hydrotalcite 16 parts

[0051] Carbon black 2 parts.

Embodiment 2

[0053] The thermoplastic polyolefin elastomer door seal rubber sleeve of the magnetic door seal is composed of the following components in parts by weight:

[0054] 50 copies of POE;

[0055] 15 parts naphthenic oil;

[0056] 25 parts of polypropylene;

[0057] 8 copies of PE;

[0058] PS 7 copies;

[0059] 1.0 parts of stearic acid;

[0060] 5 parts of calcium carbonate;

[0061] Phthalocyanine blue 0.2 parts.

Embodiment 3

[0063] The thermoplastic polyolefin elastomer door seal rubber sleeve of the magnetic door seal is composed of the following components in parts by weight:

[0064] 60 copies of POE;

[0065] 20 parts naphthenic oil;

[0066] 23 parts of polypropylene;

[0067] PS 5 copies;

[0068] 1.6 parts of PE wax;

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com