Composite light wall board and production method thereof

A light-weight wallboard and wallboard technology, which is applied to building components, pressure rollers, buildings, etc., can solve problems such as lack of heat preservation and sound insulation, harsh construction environment, and high energy consumption, and achieve good self-insulation and sound insulation effects. The overall mechanical properties are good and the effect of sufficient hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

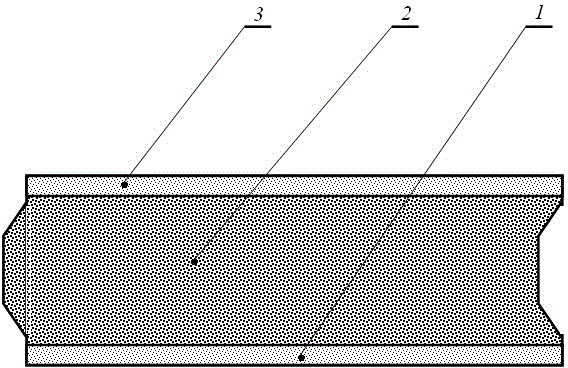

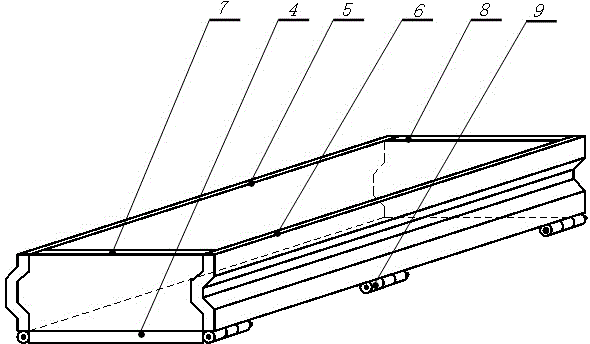

[0020] Embodiment 1: A composite lightweight wallboard, which is a three-layer composite structure formed by compounding the lower dense surface layer 1, the lightweight sandwich layer 2 and the upper layer dense surface layer 3 without gaps, and the composite lightweight wallboard The side has a notch and tenon fit shape, the inner dense surface layer and the outer dense surface layer have the same thickness, the thickness is 10mm, and the thickness of the sandwich layer is 130mm.

[0021] The composition of the lower dense surface layer 1 and the upper layer dense surface layer 3 of the composite lightweight wallboard is the same, and it is composed of mortar and a layer of alkali-resistant glass fiber mesh cloth. The composition of the mortar is medium sand, cement, and pulverized coal. Ash, fine expanded perlite, sawdust, lignin fiber, polyvinyl alcohol powder and water, the cement is ordinary Portland cement with a label of 42.5MPa, based on the addition of medium sand, ce...

Embodiment 2

[0030] Embodiment 2: A composite lightweight wallboard, which is a three-layer composite structure formed by compounding the lower compact surface layer 1, the lightweight sandwich layer 2 and the upper compact surface layer 3 without gaps, and the lightweight composite wallboard The side has a notch and tenon fit shape, the inner dense surface layer and the outer dense surface layer have the same thickness, the thickness is 5mm, and the thickness of the sandwich layer is 80mm.

[0031] The composition of the lower dense surface layer 1 and the upper dense surface layer 3 of the composite lightweight wallboard is the same, and it is composed of mortar and a layer of alkali-resistant and alkali-resistant glass fiber mesh cloth. The composition of the mortar is medium sand, cement, powder Coal ash, fine expanded perlite, sawdust, lignin fiber, polyvinyl alcohol powder and water, cement is slag Portland cement with a label of 42.5MPa, based on the addition of medium sand, cement a...

Embodiment 3

[0040] Embodiment 3: A composite lightweight wallboard, which is a three-layer composite structure formed by compounding the lower dense surface layer 1, the lightweight sandwich layer 2 and the upper dense surface layer 3 without gaps, and the composite lightweight wallboard The side has a notch and a tenon fit shape, the inner dense surface layer and the outer dense surface layer have the same thickness, the thickness is 7.5mm, and the thickness of the sandwich layer is 135mm.

[0041] The composition of the lower dense surface layer 1 and the upper dense surface layer 3 of the composite lightweight wallboard is the same, and it is composed of mortar and a layer of alkali-resistant and alkali-resistant glass fiber mesh cloth. The composition of the mortar is medium sand, cement, powder Coal ash, fine expanded perlite, sawdust, lignin fiber, polyvinyl alcohol powder and water, the cement is ordinary Portland cement with a label of 42.5MPa, based on the addition of medium sand,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com