Stress corrosion test apparatus

A technology of stress corrosion and test equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, and the use of stable tension/pressure to test the strength of materials, etc. Potential, current and other issues, to achieve the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

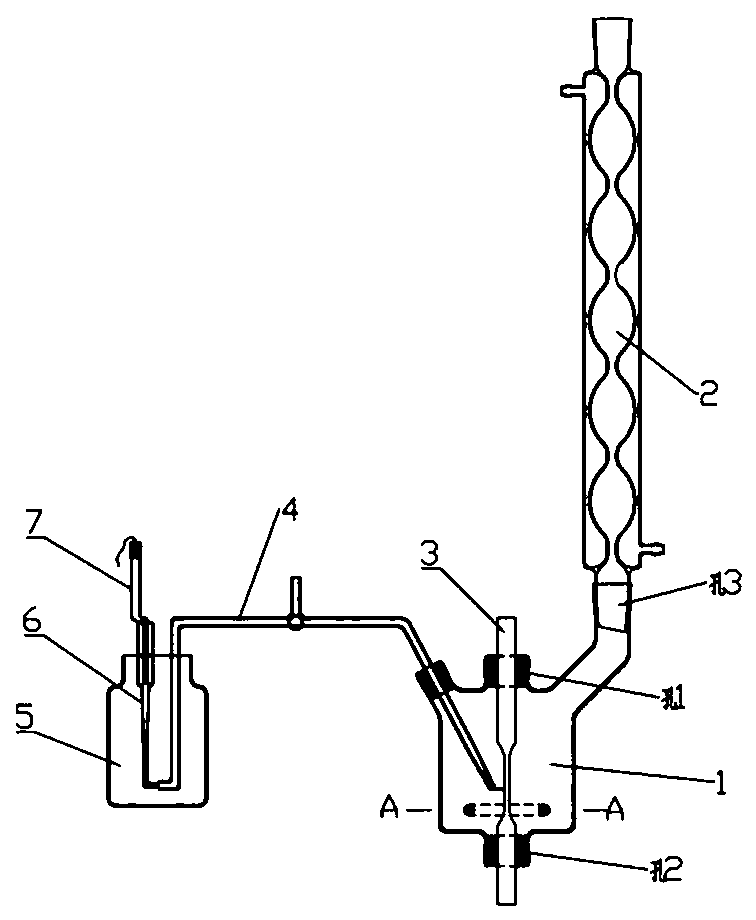

[0016] Such as figure 1 As shown in the sectional view of the stress corrosion test device, the stress corrosion test device includes a stress corrosion container (1), a spherical condenser (2), a tensile specimen (3), a salt bridge 1 (4), and a jar (5) , salt bridge 2 (6), reference electrode (7), platinum electrode, computer (8), electrochemical workstation (9), electric furnace wire (10), thermocouple thermometer (11), temperature controller (12), AC transformer (13), etc.

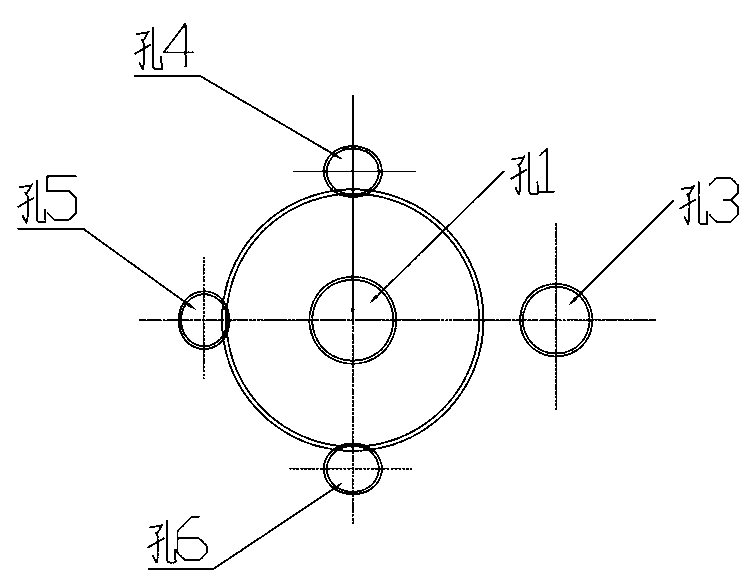

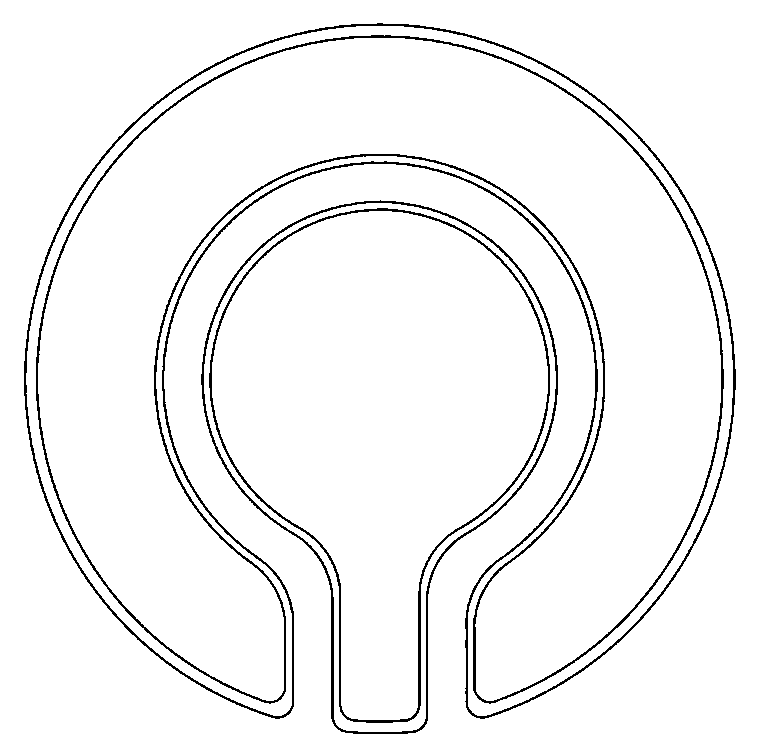

[0017] Stress corrosion container (1) is made of heat-resistant glass, with 6 holes, hole 1 and hole 2 are used to pass through the sample, hole 3 is connected to spherical condenser (2), holes 4-6 are connected to platinum electrode and salt bridge 1 (4), thermocouple thermometer (11), holes 1 to 2, and holes 4 to 6 are all sealed with rubber plugs to prevent steam from leaking and changing the concentration of the corrosive medium. When the sample is elongated, the sample and hole 2 The rubber stopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com