Core material for vacuum insulation panel and manufacturing method for same

一种真空绝热面板、芯材的技术,应用在热交换设备、绝缘改善、机械设备等方向,能够解决产生废水、芯材长期耐久性能降低、过多费用等问题,达到提高长期耐久性能、维持最佳化、降低工序费用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

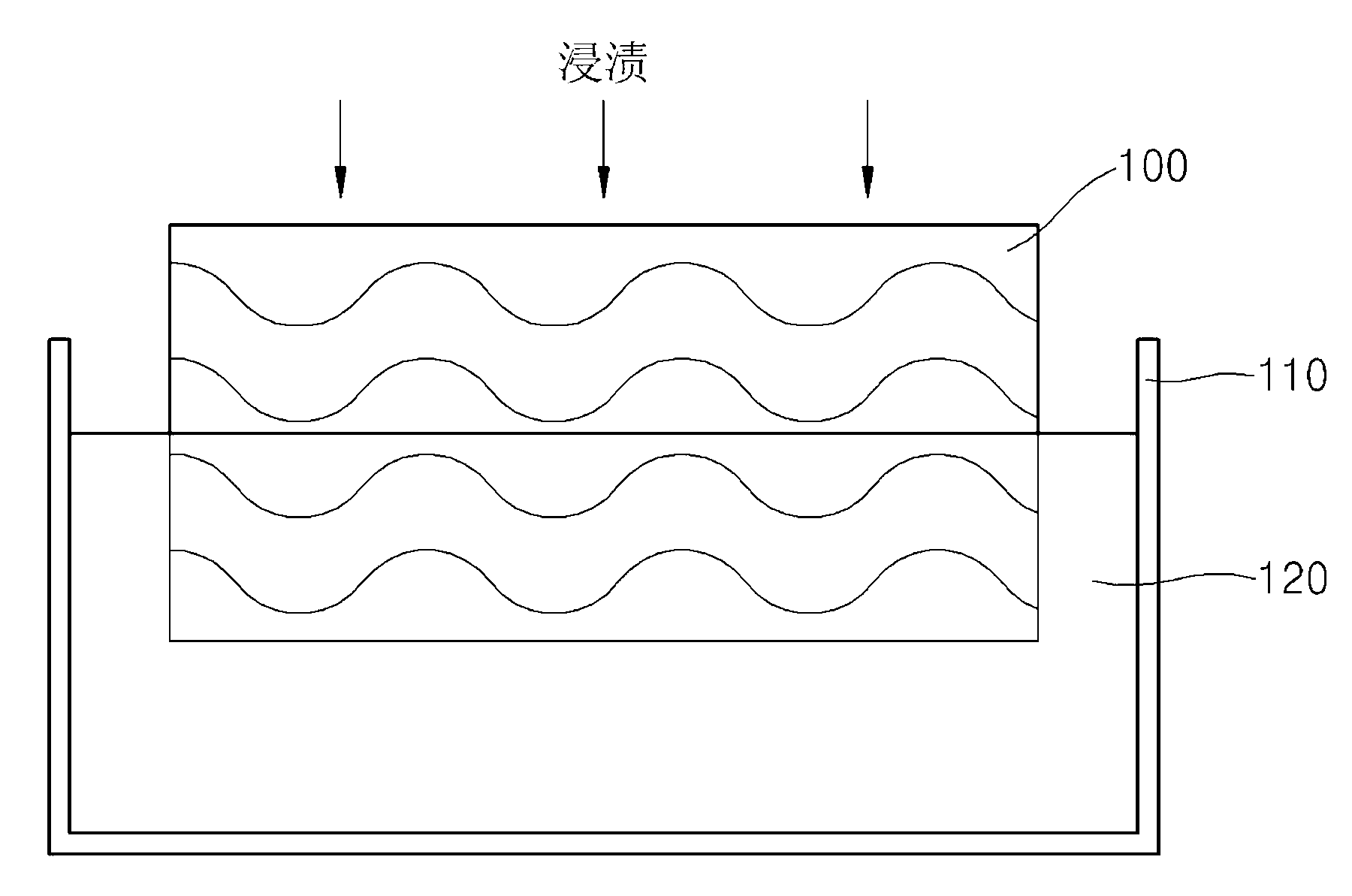

[0038] The preparation method of the core material for the vacuum heat insulation panel of the present invention firstly dips the glass wool (Glass Wool) in the solution mixed with the inorganic binder, and then fishes out the glass wool that has absorbed the inorganic binder solution. After that, the drying process is carried out while removing the residual inorganic binder.

[0039] Secondly, a skin material having a laminated structure of a surface protection layer, a metal barrier layer and an adhesive layer is formed.

[0040] Next, an absorbent prepared by packing quicklime (CaO) powder in a bag was formed.

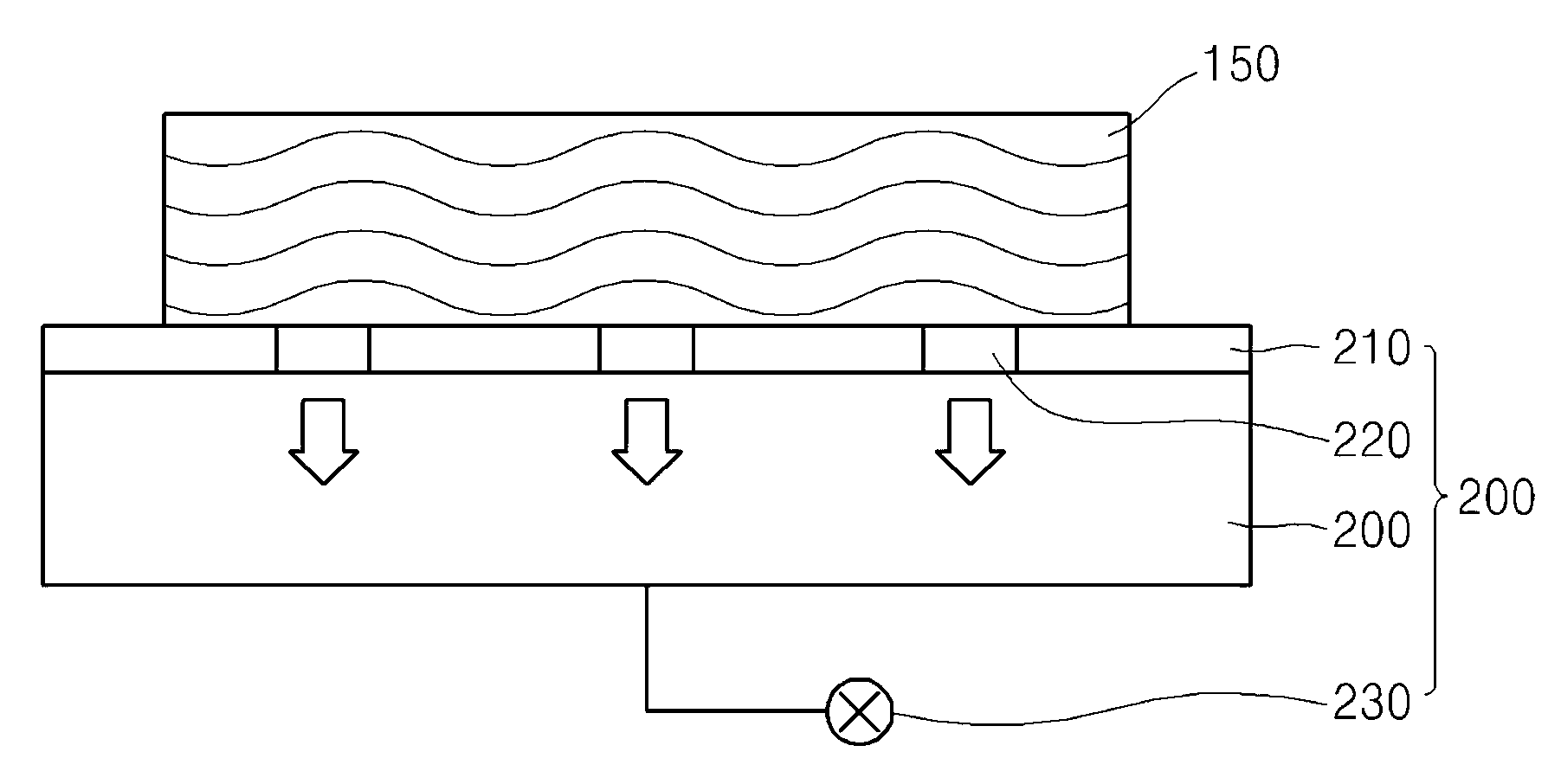

[0041]Next, the above-mentioned absorbent is attached to the upper part of the above-mentioned core material or the above-mentioned absorbent is inserted into the surface of the above-mentioned core material, and the bag is formed with the above-mentioned outer skin material, and then the core material is put into the bag and sealed in a vacuum state. Vacuum insula...

Embodiment 1

[0075] First, the above image 3 The glass wool type (Glass Wool Type) core material described in is prepared into a size of 25×300×400 mm (thickness×width×length) and used as a core material for vacuum insulation panels.

[0076] Here, the inorganic binder solution for impregnating glass wool uses silica as an inorganic binder, and prepares the silica in a sol form to be thoroughly mixed in water. Next, an aqueous silica sol solution obtained by mixing 4% by weight of silica sol and the rest of water was prepared.

[0077] Next, an external bag is formed, which is made of 12 μm polyvinylidene chloride (PVDC) / polyethylene terephthalate (PET) film, 25 μm nylon (Nylon) film, 6 μm Al Foils as well as 50 μm linear low density polyethylene (LLDPE) film structures were formed.

[0078] Next, if Figure 6 As shown, two absorbents were inserted on the surface of the core material, wherein the absorbent was prepared by packing 25 g of quicklime (CaO) with a purity of 95% into a bag....

Embodiment 2

[0081] Prepare a vacuum insulation panel with the same conditions as in Example 1 above, using an aqueous solution of silica sol mixed with 2% by weight of silica sol and the rest of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com